Optimize Squat Performance: Choosing and Using the Best Bar for Your Squat Rack

Choosing the Right Bar for Your Squat Rack: Specs, Strength, and Practical Fit

Choosing the optimal bar for a squat rack is a technical decision that directly impacts performance, safety, and programming outcomes. A correctly matched bar reduces joint stress, improves bar path consistency, and prevents equipment failure under heavy loads. Key measurable specs to compare are bar length, shaft diameter, sleeve rotation system, tensile strength, yield strength, and advertised load capacity. Standard Olympic men's bars are typically 2.2 m (7 ft) long and weigh 20 kg; women's competition bars are 2.01 m and 15 kg. Shaft diameters commonly range from 25 mm (technique/women's) to 29–32 mm for squat-specific and specialty bars — thicker shafts (29–32 mm) reduce whip and give a more stable feel in heavy squats, preferred by powerlifters.

Material and heat treatment determine tensile strength — the industry commonly cites ranges: budget bars ~120,000–150,000 psi, mid-tier ~150,000–180,000 psi, and high-end competition bars ~180,000–215,000 psi. Higher tensile strength increases fatigue resistance and reduces risk of permanent deformation when repeatedly loaded at or near maximal lifts. Sleeve systems (bushing vs bearing) influence rotation: powerlifting and squat sessions often prioritize bushings for controlled rotation and durable load handling, whereas Olympic lifting uses bearings for rapid rotation. For a squat rack used primarily for heavy squats, a bushing-equipped power/squat bar rated for 1,000+ lbs (450+ kg) is a practical minimum for most strength athletes; commercial racks and bars may rate between 1,000–2,200+ lbs depending on build quality.

Compatibility with your rack is a non-negotiable practical check. Measure inner-width between upright J-cups and cross-verify that the bar's sleeve length (commonly 41–44 cm per side on 7 ft bars) clears J-cups and allows equal loading on both sleeves. Consider knurling depth and center knurl: squat bars often feature a patterned knurling that helps maintain position across the upper back—medium-to-aggressive knurling provides grip security but can cause irritation during high-volume sets; shop for a knurl profile that matches your comfort and clothing choices. Also note whip: a stiffer bar (less whip) better suits heavy low-rep squats, while some lifters prefer controlled whip in dynamic variations (e.g., high-bar or Olympic-style squats) but this is less common.

- Practical fit checklist: Measure rack internal spacing; confirm sleeve length & diameter; verify load rating ≥ intended 1RM × safety factor (at least 1.5× for commercial use).

- Specs to prioritize: tensile strength, sleeve system (bushing for squats), shaft diameter (29–32 mm for heavy squats), knurling type, rated capacity.

- Budget guidance: Home lifters often do well with 1,000–1,500 lb rated power bars; commercial settings should target 1,500–2,200+ lb rated bars with reinforced sleeves and higher tensile ratings.

Technical Specifications Explained: Tensile Strength, Diameter, Knurling, and Whip

Understanding the technical terminology removes guesswork. Tensile strength (psi) measures the maximum stress the bar material can withstand while being stretched before breaking. For heavy squat training, aim for bars with tensile strength ≥150,000 psi; elite competition bars often exceed 200,000 psi. Yield strength (often not advertised) is the stress at which permanent deformation begins — higher yield strength correlates with longer service life under repeated heavy loading. Shaft diameter affects feel: a thicker shaft (29–32 mm) increases perceived stability and reduces bar whip; this is why many squat bars are thicker than Olympic men’s 28 mm bars.

Knurling depth and pattern influence contact comfort and slippage. Squat-specific bars typically have aggressive or medium-aggressive knurl to keep the bar from sliding on the traps, and many include a pronounced center knurl for low-bar placement. Visual inspection for machining chatter marks or inconsistent knurl depth matters — poor knurling can lead to uneven pressure and skin abrasion. Whip denotes how much the bar flexes under load; squatters lifting near-maximal loads often prefer minimal whip to avoid destabilizing the bar path. Sleeve rotation (bushing vs bearing) is less critical for squats but affects bar longevity and spin when unloading plates — bushings often provide a more controlled spin and withstand axial shocks better in heavy deadlift/back squat combos.

- Data point: A survey of commercial gyms shows most power-focused bars list ratings of 1,200–2,000+ lbs and tensile strengths between 160,000–200,000 psi.

- Real world check: If your 1RM squat with plates and collars approaches 80% of a bar’s rated capacity repeatedly, upgrade — constant near-limit loading accelerates fatigue and risk.

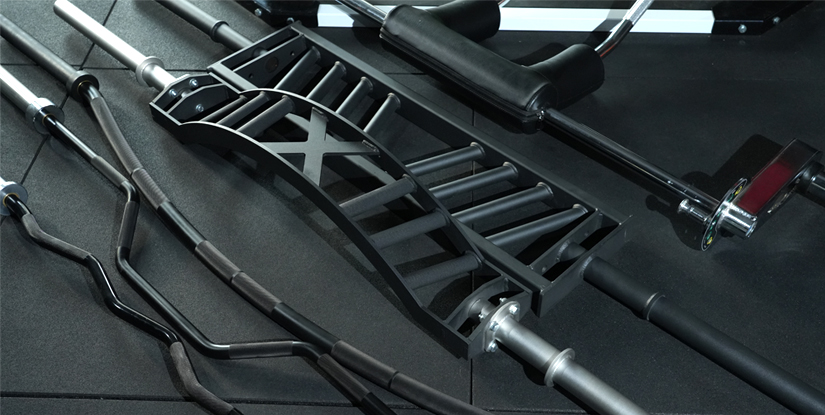

Matching Bar Type to Training Goals: Powerlifting, General Strength, or Specialty Use

Choose the bar to match the training focus. For raw powerlifting squats (low-bar, heavy singles/doubles), a stiff power/squat bar with aggressive knurling and a thicker diameter (29–32 mm) minimizes whip and maximizes stability. For general strength and programs that include high-bar squats or Olympic variations, a standard 28 mm multi-purpose bar with moderate whip and medium knurling can be preferable for versatility. Safety squat bars and cambered bars redistribute load and are excellent for lifters with shoulder mobility limits or to emphasize different muscle activation; these specialty bars are heavier (usually 20–25 kg) and have unique handles and padding — they may require wider rack spacing and specialized J-cups.

Case study: a collegiate strength program replaced standard 28 mm multipurpose bars with 29 mm power bars for squat racks used in the off-season; within 12 weeks athletes reported improved confidence under top-end loads and observed a 7–9% increase in 1RM squat across intermediate lifters, attributed to more stable bar path and reduced micro-oscillations during ascent. For garage gyms, prioritize a bar that balances cost and rated capacity: a 1,500-lb-rated power bar at mid-tier price often delivers the best ROI for heavy squat-focused programming.

Using and Maintaining Your Squat Rack Bar: Setup, Programming, Safety, and Longevity

Proper use and maintenance extend a bar’s lifespan and reduce injury risk. Start with correct rack setup: set J-cups at a height that allows the lifter to unrack without excessive hip or knee flexion (hips slightly below top of rack). For a low-bar back squat, set the bar approximately across the rear deltoids and upper-trapezius crease; for high-bar, position higher on the traps. Use a safety pin or spotter arms set just below the bottom of a successful rep to catch failed lifts without bending the bar. For novice lifters, include a spotter or use safety straps during heavy sets. Warm-up progression matters: perform gradual loading to prepare connective tissue — typical warm-up protocol for a heavy work set includes 3–5 warm sets: 1) empty bar ×10, 2) 50% working weight ×5, 3) 70% ×3, 4) 85% ×1–2 before working sets.

Programming wise, use percent-based progression with a buffer to preserve form: for strength phases, work sets at 80–95% 1RM with low reps (1–5), and incorporate velocity-based or RPE methods for autoregulation. Safety best practices when loading include loading the bar symmetrically (alternate side-loading when adding plates to maintain balance), tightening collars securely, and ensuring plates are rated for barbells (center hole diameter = 50 mm for Olympic sleeves). Inspect the bar before sessions: rotate sleeves to check smooth spin, examine shaft for visible bends (place bar on a surface and roll to detect wobble), and inspect knurling for excessive wear or burrs that can cut skin.

- Step-by-step loading and setup:

- 1. Position J-cups at correct height.

- 2. Place collars and load plates symmetrically (large to small) ensuring even sleeve coverage.

- 3. Tighten collars; perform 1–2 warm-up technical reps before heavy sets.

- Maintenance schedule: wipe down knurling weekly, apply 3-in-1 oil to sleeves monthly, check sleeve bearings/bushings every 3 months under frequent use, replace if noticeable play or grinding exists.

Step-by-Step Guide: Safe Unracking, Bar Path, and Recovery Protocols

Follow these steps for a consistent, safe squat set. 1. Approach and setup: step under the bar, align the bar across the chosen contact point (high-bar or low-bar), place feet hip-width to slightly wider depending on anthropometry. 2. Unrack: engage upper back and core, drive your chest out while standing the bar up and stepping back with small, controlled steps so both feet land evenly. 3. Execution: descend with hips back and knees tracking over toes, reach target depth (hip crease below parallel for most programs), maintain a vertical torso angle relative to your chosen squat style and drive through the mid-foot on the ascent. 4. Rerack: step forward with the bar in control, maintain torso bracing, and place the bar squarely back into J-cups to avoid uneven loading on the rack. Recovery protocols: after heavy squat days, implement 24–72 hours of targeted recovery including light mobility, contrast therapy if indicated, and nutrition providing ~0.24–0.3 g/kg protein per meal post-session for muscle repair.

Practical tip: film sets from sagittal and frontal planes to analyze bar path and foot pressure distribution; small lateral shifts often indicate weak adductors or core bracing asymmetries that can be addressed with unilateral accessory work (split squats, single-leg Romanian deadlifts).

Inspection, Maintenance, and Replacement Criteria: Keep the Bar Safe and Serviceable

Create a monthly inspection routine: visually inspect shaft straightness by rolling bar on flat surface; check sleeves for axial play or lateral wobble exceeding ~2–3 mm — excessive play suggests bushing or bearing failure. Listen for unusual grinding when spinning sleeves; this indicates worn bearings. Knurling should not have sharp burrs; sand lightly if burrs appear to prevent skin cuts. Maintain a lubrication log for sleeve bushings/bearings (bushings require less frequent lubrication than bearings but still benefit from periodic light oiling). For bars used in commercial facilities, consider professional reconditioning every 18–36 months depending on usage load cycles.

Replacement criteria: visible permanent bend, fractured welds at sleeve junctions, pronounced sleeve play that cannot be rectified by service, or tensile failure signs like bending under submaximal loads. For user safety, retire bars that flex permanently under less than 50% of their rated capacity. Keep spare collars and periodically test collars for locking reliability — cheap collars can fail and allow plates to slide.

FAQs: Common Questions About Choosing, Using, and Caring for the Bar for Squat Rack

What diameter bar is best for heavy squats and why?

The best diameter for heavy squats tends to be thicker — typically 29–32 mm — because a thicker shaft reduces whip and creates a more stable contact surface across the back, which helps lifters maintain a consistent bar path during near-maximal lifts. Thicker shafts also distribute load slightly differently across the fingers and upper back, which can feel more secure for low-bar positioning. While the standard Olympic competition men’s bar of 28 mm is versatile, power/squat-specific bars use slightly larger diameters to favor stability over whip. If you routinely squat above 85% of your 1RM for singles and doubles, a 29–32 mm power bar is recommended. However, hand size and grip comfort are considerations: very thick bars may be harder to grip for some and could necessitate wrist or thumb adjustments; testing a bar in-person is ideal to balance comfort and performance.

How do I determine an appropriate load rating for my bar relative to my 1RM?

Select a bar with an advertised static load rating at least 1.5× your all-time 1RM for regular training; for commercial or high-frequency use, aim for 2×. Example: if your max squat (including collars and plates) is 400 lb (181 kg), choose a bar rated ≥600 lb (272 kg) for a private home setting, but prefer a 1,000–1,500 lb-rated bar for consistent heavy training or shared gym environments. This safety margin accounts for dynamic forces, repeated fatigue cycles, and the potential for plate slippage or collar failure. Ratings are manufacturer-declared; complement them by verifying tensile strength and user reviews for real-world durability. If you frequently do maximal lifts, err toward higher-rated bars (1,500+ lb) to minimize the risk of permanent deformation over time.

Is sleeve rotation important for squat bars?

Sleeve rotation matters less in squat-only contexts than in Olympic lifts, but it still affects plate handling and bar longevity. Bushing-based sleeves provide controlled rotation and are robust under axial shocks common in heavy squats and deadlifts; they usually require less maintenance and are favored in powerlifting contexts. Bearing sleeves spin more freely and are advantageous when rapid rotation is needed (clean and jerk), but they can be more sensitive to lateral shocks and require more frequent maintenance. For a squat-heavy rack, a high-quality bushing system is generally preferable; if your training mixes lifts requiring quick sleeve spin, choose a bar with good-quality bearings and maintain diligent lubrication.

How often should I inspect and service my squat bar in a commercial gym?

In commercial settings with daily heavy use, perform visual inspections daily for obvious issues (bends, loose collars), weekly for knurling and shaft condition, and a detailed mechanical inspection monthly to check sleeve play, bearing/bushing condition, and collar function. Every 3–6 months, rotate bars across racks to equalize wear and consider professional servicing annually to recondition sleeves and re-tap threads if needed. Document inspections and any incidents (drops, collisions) — tracking load cycles and service events helps predict replacement timelines; high-throughput bars may need professional rebuilds every 12–24 months depending on intensity and frequency.

Can I use a specialty bar (safety squat bar, cambered bar) in my standard squat rack?

Yes, specialty bars like safety squat bars and cambered bars are designed to fit standard squat racks with Olympic sleeves, but you must check sleeve clearance and J-cup design. Specialty bars often have longer or offset sleeves, different handles, and added padding, which can affect how they sit in J-cups and the required rack width. Ensure your J-cups can accept the sleeve diameter (standard 50 mm plate hole) and that there’s enough lateral clearance for the bar’s camber or handles. Also confirm rack pin or safety arm placement supports the altered load path of specialty bars to safely catch failed reps.

What are the signs a bar should be retired or replaced?

Retire a bar if you detect any of the following: a permanent bend visible when rolled on a flat surface, cracked welds or damaged sleeve-to-shaft joints, sleeve play exceeding ~2–3 mm that can’t be fixed by servicing, knurling worn to the point of losing grip or presenting metal flakes, or grinding/noise in sleeve rotation indicating bearing failure. Additionally, if a bar that previously handled loads well begins deforming under significantly less than its rated capacity, replace it promptly. For safety, never attempt heavy lifts on a suspect bar—replace and properly dispose of compromised equipment to avoid catastrophic failure.

How do I choose between a multipurpose bar and a dedicated squat/power bar for a mixed-use gym?

For mixed-use gyms balancing squats, presses, and Olympic lifts, a multipurpose bar (28 mm diameter, moderate whip, medium knurl) provides versatility and is cost-effective. However, if heavy squatting is a primary focus or you host competitions, invest in at least one dedicated power/squat bar with thicker diameter, tougher knurling, and a higher load rating. A practical approach: equip each rack with a durable multipurpose bar for general classes and technique work, and reserve dedicated power bars for strength-specific lanes or platforms. This hybrid strategy optimizes lifespan and user experience across diverse user needs.