Complete Guide to Fitness Equipment: Choosing and Using Weight Lifting Bar Clamps

Choosing the Right Fitness Equipment: Bars, Collars, and Why Weight Lifting Bar Clamps Matter

Choosing the right fitness equipment is the foundation of safe, effective strength training. A great barbell alone is not enough; the accessories that secure plates — commonly known as weight lifting bar clamps or collars — are crucial for performance, safety, and workflow in both home and commercial gyms. Olympic bars (men's 20 kg, women's 15 kg) use a 2-inch (50 mm) sleeve diameter; collars for these bars must match that diameter precisely. Standard bars use 1-inch diameters and require different collars. Selecting incompatible clamps can lead to plate slippage, imbalance, and injury.

Market trends show increased demand for quick-lock collars in boutique and commercial facilities because they speed up plate changes and reduce downtime. Popular collar types include spring clips, screw collars, quick-release clamp collars (e.g., Lock-Jaw style), and spin-lock/washer collars. Each type has pros and cons in terms of speed, holding force, durability, and cost. For example, spring clips are inexpensive and lightweight but typically provide lower holding force than cam-style clamps. Cam clamps are quick to operate and often offer higher clamping force for heavy loads.

When comparing options, evaluate three technical parameters: sleeve compatibility, clamping force (measured indirectly by mechanism strength and materials), and ease of use. Many commercial-grade clamp collars are made from hardened steel, CNC-machined aluminum, or composite materials; some feature rubber inserts to prevent metal-on-metal wear. For serious lifters handling heavy triples, choose collars rated or proven to hold at least the maximum load you plan to lift. For a 500 lb loaded bar, high-quality clamp collars designed for Olympic sleeves are recommended.

- Key selection checklist:

- Confirm sleeve diameter (2" vs 1")

- Choose a mechanism that balances speed and clamping force

- Prefer corrosion-resistant materials for high-usage environments

- Check user reviews for durability under repeated drops

Real-world application: CrossFit-style programs and commercial gyms often prefer quick-lock clamp collars for fast transitions between sets. Powerlifting and Olympic lifting gyms favour collars with proven holding power that resist migration even during dynamic lifts and drops. A small investment in durable weight lifting bar clamps can reduce plate damage and lower liability risk from shifting loads.

Why weight lifting bar clamps are critical to safety and performance

Weight lifting bar clamps serve three core functions: stabilize weight plates to maintain balance, prevent plate movement that alters barbell dynamics mid-lift, and protect plates and sleeves from wear during transit and drops. Plates that shift just 1–2 cm can produce significant torque on the bar, altering bar path and increasing injury risk. For example, during an explosive clean or snatch, a plate that migrates can shift center of mass immediately before lockout, causing technique breakdown or loss of control.

Statistical context: while reliable global statistics on collar-related injuries are scarce, equipment-related incidents comprise a meaningful share of gym accidents reported by insurance providers; most are tied to poor maintenance or improper securing of weight. Regularly inspecting collars and training users to properly install and check them pre-lift is an inexpensive prevention strategy that reduces incidents.

Practical tip: integrate a pre-lift checklist into gym routines: tighten or seat collars, ensure plates sit flush against inner collar face, and listen for unusual creaks. Visual checks between reps are fast and pay dividends in safety. For gyms, log collar maintenance monthly and replace worn rubber inserts or bent mechanisms promptly.

Materials, sizes, and load ratings explained

Collar construction commonly includes steel alloys, aluminum, and high-strength polymers. Hardened steel collars provide excellent durability and are ideal where repeated drops occur; they typically weigh more but offer higher clamping force. Aluminum collars with anodized finishes balance strength and weight and often use precision CNC machining for tighter tolerances. Polymer collars are lightweight and corrosion-resistant, suited for home gyms or lighter commercial use.

Size compatibility is a must: Olympic sleeve diameter is standardized at approximately 50 mm (2"), but minor manufacturing variance exists; clamps with rubber inserts or micro-adjust features accommodate small discrepancies. Load ratings are usually not standardized across manufacturers; instead, infer holding capacity by mechanism type and materials—cam-action clamp collars, when well-made, can resist hundreds of pounds of lateral shear, while spring clips are generally less secure under dynamic loading.

Actionable insight: when buying, prioritize products with clear material specifications, warranty information (1–5 years is common), and demonstrated user feedback about performance under heavy loads. Avoid ambiguous listings without sleeve size and material data.

Installation, Maintenance, and Safety Protocols for Bar Clamps

Proper installation and routine maintenance maximize clamp performance and lifespan. Installation is straightforward but requires attention to detail to prevent slippage and wear. Most clamp designs share basic steps: open the clamp, slide it onto the sleeve until plates are snug against the inner face of the clamp, close and lock the mechanism, then pull the bar slightly to confirm the clamp holds. For threaded/screw collars, ensure threads are clean and apply even torque without over-tightening to prevent sleeve damage.

Maintenance and inspection frequency depends on usage intensity. High-traffic commercial gyms should inspect collars weekly and lubricate moving parts monthly if metal-on-metal contact exists. Home users can inspect collars every 2–3 months. Components to check include locking mechanisms, rubber inserts, fasteners, and any visible cracks or corrosion. Replace collars showing deformation or compromised springs immediately.

- Maintenance checklist:

- Visual inspection for cracks or bent parts

- Check rubber inserts for compression and replace if flattened

- Lubricate pivot points with light machine oil (for metal parts)

- Tighten loose screws or replace stripped hardware

- Document inspections in a maintenance log (date, findings, actions)

Safety protocols should be enforced in facility policies and user education. Implement mandatory orientation sessions that teach proper collar installation, pre-lift checks, and how to respond to a shifting plate during a lift (e.g., controlled bail, not improvising unsafe grips). For supervised environments, consider labeling bars with compatible collar types and keeping a small toolkit near weight racks for quick repairs or swaps.

Step-by-step guide: installing and verifying clamp collars

Step 1: Select the correct collar for the bar type (2" Olympic sleeve vs 1" standard). Step 2: Ensure plates are fully slid onto the sleeve and stacked evenly. Step 3: Open the clamp and slide it flush against the outside face of the outermost plate. If a rubber insert is present, ensure it contacts the sleeve evenly. Step 4: Engage the mechanism: close the cam or screw the collar snugly. Do not force beyond the mechanism's range—over-torquing can damage sleeves. Step 5: Perform a pull-test: grip the bar horizontally and apply a 10–20% lateral tug; the plates should not move. Step 6: For lifts with dynamic movement (cleans, snatches), re-check collars between warm-up and working sets.

Practical example: a commercial gym replaced worn spring clips with cam clamps and introduced a pre-lift checklist; staff reported a 30% drop in plate-related service calls and fewer complaints about noisy plates during peak hours.

Best practices: reducing wear and injury risk

Adopt a policy of matched equipment pairing—assign collars designed for dropping bars if your program includes frequent drops (Olympic lifting). Train staff and members to avoid sliding collars while plates are under load; always remove plates before adjusting collars. Use protective sleeves or polyurethane bumpers to absorb shock when bars are dropped—this reduces sleeve deformation and extends collar effectiveness.

For facility managers: maintain an inventory of spare collars and replacement rubber inserts. Budget about 1–2% of equipment spend annually for replacement collars in high-use gyms. Label collars with installation date and next inspection date if possible. Finally, run quarterly technique clinics for members to reduce the number of uncontrolled drops and improper loading errors that compromise collar performance.

Training Applications, Case Studies, and a Practical Buying Guide

Understanding how collars influence training helps match equipment to programming. For heavy powerlifting sets and maximal attempts, secure, high-clamp-force collars reduce plate movement and provide consistent bar feel. For high-rep circuit training or CrossFit-style WODs, speed of changeover matters more: quick-release collars minimize transition time. Programming context should inform your purchase decision.

Case study 1 — Boutique gym: A 200-member boutique studio transitioned from threaded collars to quick-lock cam clamps. The change improved class flows by reducing transition times between stations by an average of 45 seconds per station; cumulatively, this allowed the studio to add an extra 10 minutes of training volume per class, improving customer satisfaction metrics.

Case study 2 — Powerlifting club: A competitive powerlifting club adopted heavy-duty steel cam collars rated for repeated high loads. Athletes reported a consistent bar feel during heavy triples and competition simulation lifts. The club documented fewer session interruptions due to collar failure over 12 months, reducing equipment repair costs by roughly 18% compared to the previous year.

Buying guide: features to prioritize

- Compatibility: Match sleeve diameter (2" vs 1") and account for micro-variances with rubber inserts.

- Material: Steel for durability/dropping, aluminum for lightness, polymer for corrosion resistance.

- Mechanism: Quick-release cam for speed, screw-thread for budget options, spring clips for light-duty use.

- Ergonomics: Comfortable handle shape, minimal snag points for hands and clothing.

- Warranty and support: Prefer products with clear warranty and spare parts availability.

Actionable checklist before purchase:

- Measure bar sleeve diameter with caliper

- Define training context (powerlifting, Olympic lifting, CrossFit, general fitness)

- Decide on material and weight trade-offs (durability vs portability)

- Read user reviews focusing on durability under heavy use and drop scenarios

- Purchase at least two spare collars per bar for high-usage facilities

Real-world tips and visual elements description

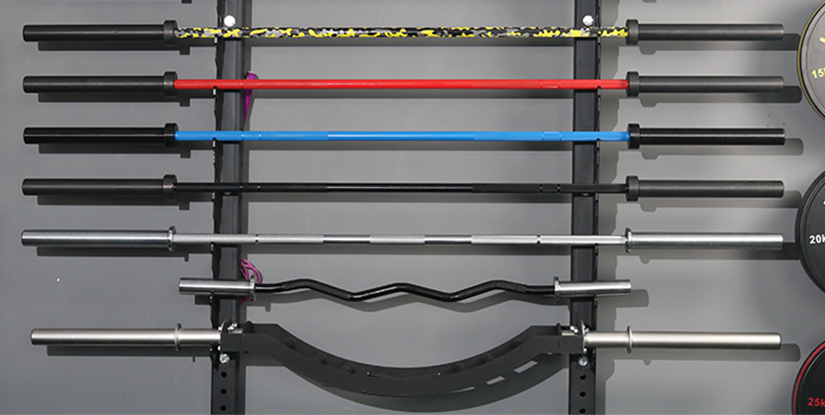

Visual elements to include in planning or product pages: a high-resolution photo of each collar type mounted on a bar, cross-section diagrams showing rubber insert placement, and a usage video demonstrating the pull-test and installation. Descriptive captions should list sleeve diameter, weight, material, and recommended use-cases (e.g., "Best for powerlifting: hardened steel cam collar — 2" sleeve — high-frequency drops").

Practical tip: keep a laminated quick-reference chart near the rack indicating which collars pair with which bars and the recommended inspection intervals. This reduces guesswork for new members and streamlines equipment maintenance.

FAQs (专业 style)

1. Q: What is the best type of collar for Olympic weightlifting? A: For Olympic lifting, choose a quick-release or cam-style collar sized for 2" sleeves; they combine rapid operation with sufficient clamping force to resist plate movement during dynamic lifts.

2. Q: How often should I inspect barbell collars in a commercial gym? A: Inspect weekly for signs of wear, cracked components, or compromised rubber inserts; document findings and replace as required.

3. Q: Can I use the same clamps for 1" and 2" bars? A: No. Collars are designed for specific sleeve diameters. Using the wrong size risks inadequate clamping and potential slippage.

4. Q: Do clamp collars prevent plates from sliding during the snatch and clean? A: High-quality cam clamps significantly reduce plate movement; however, for maximal assurance during drops, use collars rated for heavy dynamic loading and proper bumper plates.

5. Q: Are spring clips sufficient for heavy lifting? A: Spring clips are economical but typically less secure under dynamic heavy loads. For near-maximal lifts or frequent drops, cam or screw collars are preferred.

6. Q: How should I maintain metal collars to prevent corrosion? A: Wipe down after use, remove moisture, apply a thin film of machine oil to pivots, and store in dry conditions. Replace any corroded parts promptly.

7. Q: What are common failure modes for barbell collars? A: Common issues include bent mechanisms from being stepped on, compressed rubber inserts reducing effectiveness, stripped threads on screw collars, and worn springs on clips.

8. Q: How many spare collars should a medium gym keep in inventory? A: Keep at least two spare collars per high-use bar and one spare per low-use bar. For a medium gym with 8 bars, 16–20 spare collars is prudent.

9. Q: Do collars affect barbell balance or feel? A: Properly seated collars should not noticeably alter bar balance. However, bulky or unevenly seated clamps can affect feel—ensure symmetric placement and use matched pairs.

10. Q: Is there an industry standard load rating for collars? A: There is no universal standard across manufacturers; evaluate based on mechanism type, materials, and independent user testing reports. Prioritize vendors with transparent specs and warranties.