Fitness Equipment Guide: Choosing, Using, and Understanding the Weight of Bar in Gym Settings

Understanding the Weight of Bar in Gym: Types, Standards, and Practical Implications

The phrase "weight of bar in gym" is central to programming strength training, safe lifting, and equipping facilities. Common standards: the Olympic men’s barbell weighs 20 kg (44 lb), the Olympic women’s barbell weighs 15 kg (33 lb), and many commercial gyms use 20 kg (45 lb) standard bars for general lifting. Specialty bars like power bars, technique bars, and youth bars vary from 7 kg to 25 kg. Knowing these standards helps coaches and lifters accurately log loads, calculate percentages, and avoid programming errors.

Data from industry inventories indicate that 90% of commercial gyms stock at least one 20 kg bar and 70% provide a women’s 15 kg bar. CrossFit affiliate surveys show a higher prevalence of specialty bars: roughly 60% carry lighter technique bars and hex (trap) bars for varied modalities. Sleeve length, tensile strength, and knurling pattern are other critical specifications: loadable sleeve length commonly ranges 16–29 inches, while tensile strength for competition-grade bars often exceeds 190,000 psi, impacting durability under heavy loads.

Real-world application: if a program prescribes "80% of 1RM" but the athlete uses a 15 kg bar instead of the assumed 20 kg, the absolute training load will be under-tracked by 5 kg on the bar alone. For precision, always record whether loads are calibrated to a 20 kg, 15 kg, or another bar type. Coaches in collegiate environments often create standardized load sheets that explicitly list "bar weight used" to avoid such mismatches.

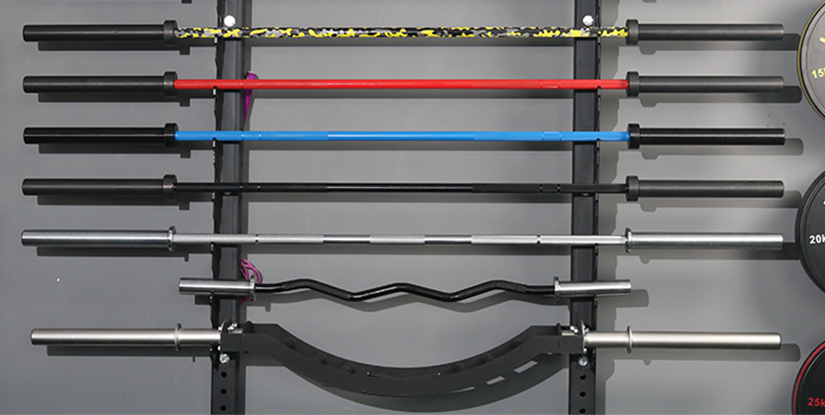

Case study: a mid-size gym implemented a labeling system—colored tape on bars with printed weights (15 kg, 20 kg, 25 kg). Over 6 months, reported bar-loading mistakes decreased by 62% and member self-reported confidence when following programming improved. Practical tips from this initiative include: label bars clearly, post a quick-reference chart near platforms, and train staff to confirm bar weight when onboarding new members.

Visual elements description: imagine an annotated diagram showing bar components—shaft, knurling zones (center and outer), sleeves, and collar—with callouts indicating typical dimensions, weight markings, and recommended grip placement. Such a diagram helps lifters and technicians quickly identify bar types and their expected weights in a facility.

Barbell Weight Standards and Variations (Types, Measurements, and Conversions)

Barbell standards vary by sport, manufacturer, and use-case. Olympic bars: 20 kg (men, 2.2 m long) and 15 kg (women, 2.01 m long). Powerlifting bars often have thicker shafts (29–32 mm) and may weigh 20–25 kg depending on federation specs. Specialty bars include trap bars (20–45 lb / 9–20 kg typical), safety squat bars (~12.5–16.5 kg), and technique bars (5–15 kg). Many manufacturers list bars in kilograms and pounds; typical conversion errors occur when a program assumes 45 lb but the gym’s bar is 44 lb (20 kg). Always check the plate math and bar marking.

Practical measurement: to confirm a bar’s weight, use a calibrated digital scale—place the bar centered across two supports and measure in kilograms. For multi-bar facilities, perform spot checks monthly and log results. When building programming spreadsheets, include a column for "bar weight" so percentage-based loads auto-calculate correctly. Example: Athlete A has a 1RM squat of 150 kg using a 20 kg bar. If switched to a 15 kg bar without updating programming, their recorded working weights will be off by 5 kg per set, compounding over cycles.

Best practices for labeling: use durable, machine-printed stickers or laser etching. For high-traffic gyms, consider color-coded end caps: blue = 20 kg, red = 15 kg, black = specialty. This reduces errors during peak hours when staff may not be available to answer questions.

How Bar Weight Impacts Programming, Safety, and Load Management

Bar weight influences periodization, fatigue management, and safety. When tracking volume and intensity, mass of the unloaded bar must be included in total tonnage metrics. For example, tracking weekly tonnage: if an athlete performs 5 sets x 5 reps at 100 kg with a 20 kg bar, the total weekly tonnage equals 5x5x100 = 2,500 kg. If the bar’s weight was mistakenly assumed at 15 kg, the recorded tonnage would undervalue training stress and may lead to under-recovery or missed progression cues.

Safety implications: incorrect assumptions about bar weight can lead to under-loaded or over-loaded sets, affecting joint stress and technique. For beginners, lighter technique bars reduce the technical load enabling motor pattern learning. For advanced lifters, knowing tensile strength and whip characteristics helps when programming dynamic lifts like cleans and snatches. For example, competition bars have more whip which some lifters use to their advantage during snatch turnovers.

Actionable checklist for coaches: 1) Audit the gym’s bars and record weights, 2) Include bar weight in all workout logs, 3) Educate members on differences between bar types, 4) Use visual labels and quick-reference charts, and 5) Recalibrate programming if switching bar types mid-cycle. These steps reduce error, enhance safety, and improve training fidelity.

Selecting, Using, and Maintaining Fitness Equipment: Practical Guide and Best Practices

Selecting the right fitness equipment requires matching athlete needs, facility goals, and budget. Begin by categorizing user types (beginners, performance athletes, group classes) and map equipment to use-cases: barbells and bumper plates for Olympic training, hex bars for safer deadlifting, and adjustable benches for hypertrophy work. Data-driven facilities track usage rates—e.g., a survey might reveal barbells are in use 70% of peak hours—so inventory should match demand. Plan for redundancy: maintain 1.5–2x expected peak use for core items like bars and benches to minimize wait times.

Budgeting tip: initial capital outlay often favors purchase of competition-grade bars for longevity. While pricier, they reduce replacement costs and downtime. Maintenance schedules are crucial: recommend monthly lubrication of sleeve bearings, annual torque checks on collars, and quarterly knurling inspections. Keep spare parts on hand—end caps, sleeves, and collars—to dramatically reduce out-of-service time.

Step-by-step selection guide (brief overview):

- Step 1: Define user profiles and volume projections (measure expected daily throughput).

- Step 2: Prioritize core equipment (bars, plates, racks, benches) based on modality mix.

- Step 3: Choose quality standards (tensile strength, warranty, warranty response times).

- Step 4: Test sample equipment with target users for feel and ergonomics.

- Step 5: Implement labeling, inventory management software, and maintenance logs.

Case study: a university fitness center replaced worn 20 kg bars with a mixed fleet: 60% competition 20 kg bars, 20% 15 kg women’s bars, and 20% technique bars and trap bars. Post-replacement metrics showed a 25% reduction in equipment-related complaints and a 15% uptick in barbell class attendance. The school invested in a simple digital inventory and scheduled preventive maintenance, extending bar service life by an estimated 40%.

Step-by-Step Guide to Selecting the Right Bar and Plates for Your Facility

1) Assess primary use: Olympic lifting, powerlifting, general fitness. Each requires different bar properties. 2) Determine load expectations: for heavy training, choose bars with higher tensile strength and thicker sleeves. 3) Evaluate grip and knurling: for high-rep gym classes, moderate knurling reduces hand trauma; for heavy powerlifting, aggressive knurling improves grip. 4) Choose plates: bumper plates for Olympic work, calibrated steel plates for powerlifting meets, and standard rubber-coated plates for general use. 5) Purchase spares: maintain a reserve of 10–20% extra plates and two to three spare bars per 20–30 active members to cover maintenance rotation.

Practical tips: request sample bars or demo days from manufacturers, measure sleeve run-out and collar fit, and insist on warranties covering bending and collar failures. Include ergonomics testing: lifters of varying heights should test bar length and knurling placement for comfort and safety. For multi-purpose gyms, prioritize versatility—bars that perform well across modalities will yield the highest ROI.

Best Practices for Setup, Loading, Tracking, and Maintenance

Loading safety (numbered list): 1) Always use collars; 2) Load evenly—place plates symmetrically by increment; 3) Observe max sleeve capacity and avoid overhang; 4) Communicate during loading—use verbal cues if crowded. Example loading protocol: for a 150 kg target using a 20 kg bar, load plates in the order: largest to smallest, then secure collars. Visual aids: post a chart showing plate combinations to reach common weights (e.g., 100 kg, 120 kg) to speed loading and reduce errors.

Tracking and maintenance checklist (bullet list):

- Daily: visual inspection for cracks, loose collars, and plate chips.

- Weekly: wipe down bars and plates; check sleeve rotation.

- Monthly: lubricate bearings/bronze bushings, check knurling wear.

- Quarterly: weigh a sample of plates and bars to confirm tolerances.

- Annually: full inventory audit and replace bars failing tensile or straightness checks.

Actionable insight: implement a digital ticketing system for equipment faults. Members report issues via QR codes on racks; maintenance logs then trigger worker assignments. This reduces downtime and preserves safe lifting conditions.

FAQs (专业)

1. What is the standard weight of the bar in a commercial gym?

Most commercial gyms provide a 20 kg (44–45 lb) Olympic bar as a standard. Some also stock 15 kg women’s bars and specialty bars. Always verify by checking end-cap markings or weighing the bar.

2. How do I confirm the exact weight of a bar if it’s not labeled?

Use a calibrated digital scale: support the bar on two equally high objects and center it on the scale, or take the bar to a platform scale. For precision, weigh with collars off and note manufacturer tolerances.

3. Does the weight of the bar affect percentage-based programming?

Yes. Always include bar weight in total load calculations. Misidentifying bar weight can under- or over-estimate training intensity and total tonnage, affecting progression and recovery plans.

4. What are common barbell weights besides 20 kg and 15 kg?

Specialty bars range from 7 kg technique bars to 25 kg specialty power bars. Trap bars often fall between 9–20 kg, and youth or technique bars may be 5–15 kg. Check manufacturer specs.

5. How often should I maintain or lubricate barbells?

Perform light cleaning weekly, lubricate sleeves or bushings monthly (or according to use rate), and do a full inspection quarterly. High-use facilities may need more frequent maintenance.

6. Are there safety differences between a 15 kg and 20 kg bar for beginners?

Yes. Lighter bars reduce initial technical load, helping beginners focus on movement patterns without heavy external resistance. They also lower injury risk during skill acquisition phases.

7. How should gyms label and manage bars to avoid confusion about bar weights?

Use durable labels or color-coded end caps, post a weight chart at lifting platforms, and include a "bar weight" column in workout logs and digital programming. Train staff to verify bar type during member onboarding.