Complete Guide to a Functional Trainer with Squat Rack: Buy, Setup, Program, and Maintain

Overview: What a Functional Trainer with Squat Rack Is and Why It Matters

A functional trainer with squat rack combines a cable-based pulley system with a free-weight, barbell-friendly rack. This hybrid design enables both high-control, variable-resistance movements and heavy compound lifts like squats, bench presses, and overhead presses. For gym owners, personal trainers, and dedicated home athletes, the configuration reduces footprint and increases exercise variety — one frame covers cable crossovers, single-arm rows, lat pulldowns (with attachments), plus barbell squats and rack-based safety work.

Market demand has driven innovation: compact hybrid rigs are increasingly common in boutique studios and higher-end home gyms. Industry indicators show the overall home and commercial fitness equipment market expanding post-2020, with hybrid units appealing because they replace multiple machines. For example, a single commercial-grade functional trainer with squat rack typically replaces a cable station, squat rack, and sometimes a smith or leg press machine, freeing floor space and delivering a lower total cost of ownership over five years.

Key performance metrics to evaluate include maximum load capacity, pulley ratio, attachment compatibility, rack pinhole spacing, footprint, and plate storage. Typical commercial units offer rated capacities from 600 lb per pulley to integrated 1,500+ lb rack supports. Pulley ratios vary; a 2:1 reduction means 100 lb on the handle may actually lift 200 lb on the weight stack or plates — understanding this impacts programming and accurate load progression.

Use cases span: personal training in small studios, corporate wellness rooms, rehabilitation clinics where controlled cable resistance is preferred, and performance centers where barbell work remains essential. The blend of unilateral cable work and bilateral barbell lifts supports balanced strength development, improved stability, and functional movement patterns that translate to sport and daily life.

Key Technical Specifications to Evaluate Before Purchase

Selecting the right model starts with measuring how you'll use it. Important specs include:

- Load ratings: rack uprights (e.g., 1,000–2,000 lb safe working load) and pulley capacity (per cable)

- Pulley ratio: 1:1 vs. 2:1; determines perceived resistance and how many plates you actually need

- Adjustable carriage range: vertical travel and anchor points for handles

- Pinhole spacing on the rack: 1-inch increments are ideal for precise racking and safety bar height

- Space and footprint: depth and width including barbell loading clearance and cable travel radius

- Compatibility: ability to accept Olympic plates, storage pegs, chin-up bars, landmine attachments, and safety arms

Practical tip: Measure your ceiling height and allow at least 12–18 inches above the top of the rack for bar path clearance (more if you’ll use a long bar for overhead lifts). Visual description: imagine a front-view diagram showing bar path, attachment points, and the footprint with a 2D floor plan overlay indicating where plates and benches will fit.

Benefits, Performance Outcomes, and Real-World Applications

Combining a functional trainer with squat rack delivers multiple performance benefits. First, it improves training efficiency: having cable and barbell options in one station shortens transition time between sets. In commercial settings, throughput increases because clients can work in circuits — e.g., cable row superset into barbell back squat — without moving between machines.

Second, the hybrid setup promotes balanced development through unilateral and bilateral modalities. Cables allow constant tension through joint arcs, reducing sticking points and facilitating tempo work, while the rack supports maximal strength training. Research and practitioner reports indicate that integrating both modes increases hypertrophy and neuromuscular adaptations when programmed concurrently: for instance, pairing heavy squats (3–6 reps) with cable accessory work (8–15 reps) optimizes motor unit recruitment and muscle balance.

Third, safety and rehabilitation use cases benefit from the adjustable safety pins and the controlled resistance of cables. Physical therapists value the precise resistance scaling and eccentric control cables provide; a patient recovering from knee surgery can start with low, variable load single-leg cable extensions before progressing to loaded rack work as strength returns.

Real-world applications vary by environment:

- Home gyms: space-conscious athletes use the unit for full-body training, prioritizing plate storage and bench compatibility.

- Boutique studios: functional trainers enable group classes to rotate stations, combining strength and conditioning segments efficiently.

- Commercial gyms: heavy-duty units withstand high daily usage cycles and reduce equipment redundancy.

Case Studies and Data-Driven Examples

Case study 1: A boutique studio replaced three pieces (dual cable machine, half rack, and lat tower) with two hybrid rigs, increasing usable floor space by 18% and enabling 20% more small-group classes per week. Revenue per square foot improved by an estimated 12% within six months due to higher booking rates.

Case study 2: In a corporate wellness pilot with 150 employees over six months, inclusion of a hybrid trainer improved engagement metrics: 35% of participants reported using the station weekly, and strength testing showed average squat 1RM increases of 8–12% in novices who followed a structured 12-week program integrating both cable accessory sessions and rack-based strength days.

Data note: When evaluating ROI, count not only equipment cost but also reduced need for multiple machines, plate and attachment consolidation, and potential membership retention gains driven by variety and programming effectiveness.

How to Buy, Site, and Assemble a Functional Trainer with Squat Rack

Buying and installing a hybrid unit requires planning. Follow a checklist to avoid common pitfalls: confirm ceiling height, floor loading (concrete floor vs. wood), delivery/installation logistics, warranty coverage, and service access for cables and pulleys. Many manufacturers offer on-site installation; for home installations, expect two adults and 2–4 hours for assembly for commercial-grade frames — less for modular home models.

Cost breakdown: entry-level home hybrids can start around $900–$1,800, mid-range commercial-lite models $2,000–$5,000, while full commercial rigs with dual pulleys, stainless-steel carriages, and integrated plate storage run $6,000–$12,000+. Factor in accessories: adjustable bench $200–$800, Olympic barbell $150–$400, bumper plates $2–3 per lb for good quality, and landmine/lat pulldown attachments $100–$400.

Best practice: prioritize durability features—weld quality, powder-coat finish, and nylon-bushed pulleys—over cosmetic extras. Warranty terms are critical: look for at least 2–5 years on the frame and 1–2 years on moving parts for commercial settings.

Step-by-Step Assembly, Placement, and Safety Checklist

- Unpack and inventory parts against manufacturer list. Photograph any damaged pieces immediately for claims.

- Position base plates and align uprights; loosely fasten bolts first, then torque to spec in a criss-cross pattern.

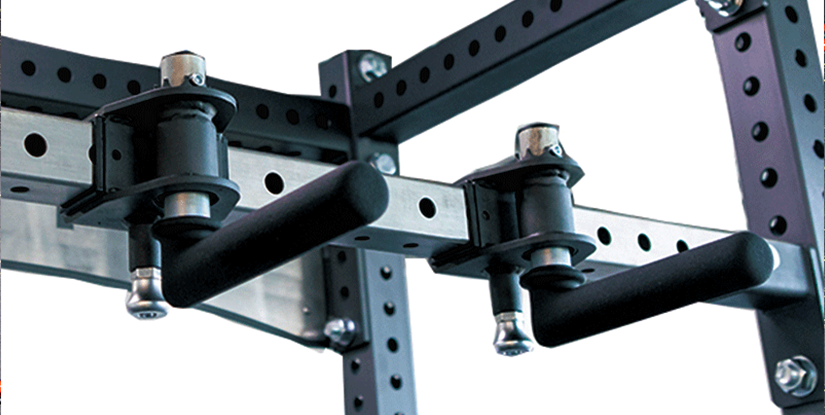

- Install pulleys and cable runs, checking for smooth travel; route cables as instructed to avoid chafing points.

- Fit safety spotter arms, J-cups, and any adjustable carriages; verify pinhole alignment across both uprights.

- Attach accessories (lat bar, handles, landmine) and test range of motion without load, then with light plates to confirm stability.

- Perform a safety audit: confirm floor anchoring if required, ensure 360-degree clearance (minimum 3–4 ft around), and mark high-traffic zones.

Practical tip: Use a spirit level and a torque wrench. If installing in a multi-level building, consult a structural engineer to confirm floor load capacity when planning heavy plate stacks or high-rep group usage.

Programming, Workouts, and Maintenance for Long-Term Performance

Programming around a functional trainer with squat rack allows periodized cycles incorporating maximal strength, hypertrophy, and functional conditioning. A balanced weekly split could include two heavy barbell days (e.g., squat and deadlift days), two accessory days using the cable system for unilateral and core work, and one conditioning day combining sleds, sled-like pushes, and cable-resisted carries. This hybrid approach leverages both absolute load capacity and constant tension for comprehensive adaptation.

Quantifiable progression: track barbell 1RM and estimated working sets for progressive overload, while recording cable resistance as plate equivalents adjusted for pulley ratio. Example: if your cable setup is 2:1 and you place 50 lb plates (per side) the effective load on a single-handle exercise is 100 lb; log both plate weight and effective load in training notes for precise progression.

Maintenance schedule: inspect cables and housings monthly in high-use environments, lubricate guide rods per manufacturer guidelines, and replace worn nylon bushings or pulley wheels when lateral play appears. Safety pins and J-cups should be checked weekly in commercial facilities. Proper maintenance extends life and preserves warranty compliance.

Sample 8-Week Training Plan and Tracking Protocols

Eight-week microcycle example (overview): Weeks 1–4 focus on volume (3 sets × 8–12 reps on accessory cable work; 4 sets × 6–8 reps on main barbell lifts). Weeks 5–8 emphasize intensity (5 sets × 3–5 reps heavy barbell work; accessory cable work 3 sets × 10–15 focused on tempo and eccentrics).

- Day A: Heavy squat (progressive sets), cable Romanian deadlift (3×10), single-arm cable row (4×8 each), core Pallof press (3×12)

- Day B: Bench or press in rack (5×5), cable face pulls (4×15), Bulgarian split squat (3×8), loaded carry with landmine or cables (4×40m)

- Day C: Dynamic effort lower (speed squats), circuit of cable chops, pull-throughs, and sled/conditioning

Tracking protocol: use a simple spreadsheet logging date, exercise, plate weight, pulley plate equivalents, sets, reps, RPE, and notes on form or pain. Visual element description: a sample spreadsheet screenshot would show columns for each metric and a small chart plotting 1RM trends and weekly volume to identify plateaus or overreaching.

10 Professional FAQs

- Q: Is a functional trainer with squat rack suitable for heavy Olympic lifting?

A: It supports heavy barbell lifts if the rack’s uprights and J-cups are rated for sufficient load and have narrow pinhole spacing for correct bar placement; however, dedicated Olympic platforms and racks are preferred for competitive lifts due to bar bounce and floor shock considerations. - Q: How do pulley ratios affect exercise selection?

A: A 2:1 ratio reduces the felt load and lets you use lighter plate stacks for equivalent resistance; use 1:1 for direct plate-to-handle relationships when precise loading is needed. - Q: What are the maintenance priorities?

A: Monthly cable inspections, pulley wheel checks, bolt torque verification, and annual replacement of high-wear components in commercial settings. - Q: How much space do I need around the unit?

A: Minimum 3–4 ft clearance on all sides and additional overhead space; allow extra for barbell loading and bench movement. - Q: Can rehab protocols be performed safely?

A: Yes—start with low-load, high-control cable work and progress to rack-supported lifts as strength and movement patterns return; always follow clinician guidance. - Q: What accessories should I budget for?

A: Adjustable bench, Olympic bar, bumper plates, landmine, lat/row bar, assorted handles, and plate storage pegs. - Q: Is plate storage needed?

A: Yes—integrated storage keeps plates off the floor, reduces trip hazards, and balances the frame under load. - Q: How to integrate into group classes?

A: Use it as a station in circuits: pair a 90-second cable metabolic drill with a 3-rep heavy rack movement rotated across groups to maintain safety and flow. - Q: What warranty terms should I expect?

A: Commercial units typically carry longer frame warranties (3–10 years) and shorter parts warranties (1–3 years); confirm labor and shipping terms. - Q: Can I use specialty bars?

A: Most commercial racks accept Olympic bars; hex/trap bars or specialty cambered bars may require additional space or adapters for safe use.