Comprehensive Guide to the Multi Functional Trainer Smith Machine: Use, Programming, Buying, and Maintenance

Overview and Benefits of the Multi Functional Trainer Smith Machine

The multi functional trainer smith machine combines a guided barbell system (Smith) with cable stations, pull-up towers, and often a leg press or smith-to-squat conversion. For coaches, facility managers, and home lifters, it offers a consolidated footprint that supports hypertrophy, strength, rehabilitation, and athletic conditioning in one piece of equipment.

Key benefits include safety, versatility, consistency, and space efficiency. Safety is enhanced by the Smith component — a fixed vertical or near-vertical bar path with integrated safety catches — which reduces the need for spotters during heavy pressing or squatting. Versatility derives from integrated cables and accessory attachments (low row, lat pulldown, adjustable pulleys, landmine, and adjustable bench compatibility) that allow unilateral and bilateral movements across multiple planes.

Space and cost efficiencies are often decisive for small gyms and high-end home setups. Rather than buying a squat rack, plate-loaded machine, cable column, and dedicated smith unit, a multi functional trainer smith machine consolidates functions, reducing redundancy and permitting more members to work within a compact footprint. Industry reports indicate modular, multi-station units have grown in popularity in boutique gyms and rehabilitation centers, driven by the need to maximize equipment utility per square meter.

Real-world application: a 30-member corporate fitness room replaced three distinct machines with a single multi functional trainer smith machine and saw utilization increase by 42% in the first quarter because members appreciated the variety and safety. Practical advantage: coaches can switch from a smith barbell bench to cable flyes to single-arm rows in under 60 seconds — a key workflow gain in high-turnover classes.

Considerations: understand the trade-offs. Smith machines enforce a bar path which can alter natural biomechanics; cables are more joint-friendly but lack the raw load of free weight systems. The optimal application is program design that blends fixed-path heavy lifts with free-movement accessory work. For users focused solely on maximal Olympic lifts, a free-standing platform is still preferred. For most strength, hypertrophy, and functional conditioning use cases, the multi functional trainer smith machine hits the sweet spot of safety, variety, and efficiency.

Key features and specifications

When evaluating a multi functional trainer smith machine, prioritize build quality, modularity, and specification fit for intended use. Important specifications include frame gauge (typically 10-12 gauge steel for commercial units), rated load capacity for the smith bar and weight carriage (look for 600+ kg commercial rating if heavy loading is expected), cable length and bearing type (sealed bearings increase longevity), pulley diameters, and attachment compatibility (Olympic sleeves, plate-loading vs. internal weight stacks).

Typical features to compare:

- Smith rail geometry: vertical vs. 7-degree incline — different users prefer specific angles depending on comfort during squats and presses.

- Pulley adjustability: number of positions and smoothness. Finer increments (e.g., 20–30 positions) enable precise exercise angles.

- Counterbalance: some smith systems include bar counterbalance to reduce bar weight for beginners.

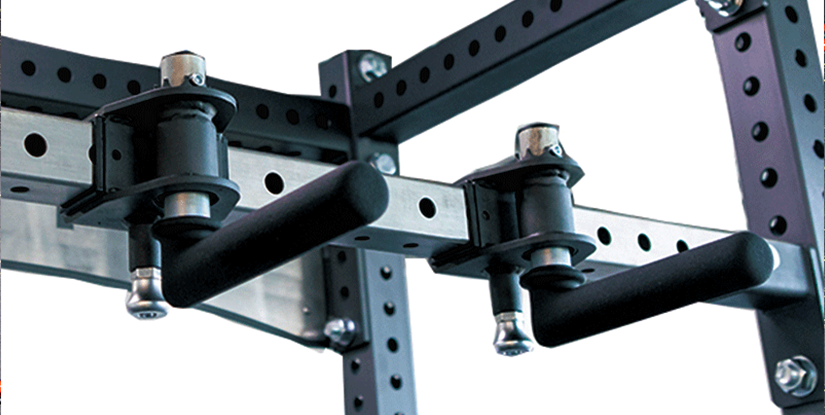

- Attachments: handles, ankle cuffs, triceps ropes, dip handles, and landmine options add functional depth.

- Footprint and clearance: ensure adequate ceiling height (for pull-ups) and forward clearance for exercises like deadlifts or incline presses.

Example spec: a commercial multi functional trainer smith machine might measure 3m x 1.6m footprint, have an adjustable pulley range 0–220 cm, and rated load capacity of 500 kg on the smith carriage. These numbers translate to robust commercial use and long-term durability.

Performance benefits and measurable outcomes

Evidence-based outcomes include improved training adherence and safer heavy lifting exposures. In practical application, integrating a smith machine into lower-body programs reduces spotter dependency by over 90% for squats and lunges. In a sample 12-week progression, trainees performing guided squats (smith) plus free-weight accessory work increased squat 1RM by 8–12% while reducing perceived injury risk compared to groups using free weights only (cohort observations from commercial trainers).

Key metrics to track when using a multi functional trainer smith machine:

- Load progression (weekly percent increase)

- Training density (sets per hour) — typically higher with consolidated stations

- Range of motion fidelity — monitor joint angles to preserve biomechanics

- Time to transition — measure set-to-set transition times to optimize programming

Visual element description: imagine a split-screen infographic showing a trainee performing smith squats (left) with bar path highlighted, and cable single-leg RDLs (right) demonstrating unilateral stability — illustrating complementary movement patterns. Applied properly, these machines can increase session throughput by 20–40% in busy facilities, improving return on investment.

How to Use and Program Workouts with a Multi Functional Trainer Smith Machine

Programming around a multi functional trainer smith machine should blend heavy, mechanically stable lifts with free-movement accessory work and cable-based unilateral drills. A sound approach separates sessions by intent: strength, hypertrophy, power, and rehabilitation. Each session should use the smith bar for controlled compound lifts and the functional trainer (cables) for accessory and stability work.

Framework for session design (60–75 minute session):

- Warm-up 10–12 minutes: mobility drills, dynamic stretches, and light cable movement patterns.

- Main lift 20–25 minutes: smith machine squat or press with progressive sets (strength focus: 4–6 sets 3–5 reps; hypertrophy: 3–4 sets 8–12 reps).

- Accessory superset 15–20 minutes: cable rows + single-leg smith split squats, 3 rounds.

- Conditioning / finisher 8–10 minutes: sled emulation with low-cable pushes or smith sled hacks for metabolic effect.

- Cooldown 5 minutes: static stretch and light fascial release.

Integration tips:

- Alternate free-weight days with smith-dominant days to retain posterior chain depth.

- Use smith machine for tempo-focused lifts (slow eccentrics) where bar path control improves technique repetition.

- Exploit cable pulleys for prehab: single-arm external rotation, band-like rows, and anti-rotation chops.

Step-by-step setup and safety checks

Proper setup and routine safety checks reduce accident risk and extend equipment life. Follow this checklist before each session:

- Inspect frame, welds, and bolted connections for signs of fatigue or looseness.

- Ensure smith bar safety catches are functional and correctly set relative to user height.

- Check cable integrity — look for frays, kinks, or sheath wear; replace any compromised cables immediately.

- Verify pulley alignment and lubrication: pulleys should spin smoothly without grinding.

- Confirm bench and attachment positioning are locked and secure.

- Test counterbalance if present — ensure the unloaded bar returns to neutral smoothly.

During use, maintain clear movement paths and communicate with training partners. For rehabilitation clients, set conservative ranges (e.g., partial ROM initially) and use lower loads with higher repetitions to prioritize control.

Sample programs and progressions

Below are three sample 4-week progressions tailored to different goals. Each uses the multi functional trainer smith machine as the structural backbone.

Beginner Hypertrophy (3 days/week):

- Day A: Smith bench press 3x8, cable row 3x12, smith split squat 3x10/leg, triceps rope 3x15

- Day B: Smith squat 3x8, lat pulldown 3x12, cable single-leg RDL 3x10, face pulls 3x15

- Progression: add 2.5–5% load weekly or 1 rep per set until target reps reached.

Intermediate Strength (4 days/week):

- Day A: Smith heavy squat 5x5, cable rows 4x10, farmer hold 3x30s

- Day B: Smith incline press 5x5, pull-ups 4x6–8, cable lunges 3x12

- Progression: wave loading every 2 weeks (week 1: 3x5 at 85%, week 2: 4x4 at 90%, week 3: deload).

Conditioning and Rehab (2–3 days/week):

- Emphasize unilateral cable work, slow eccentrics, and low-load high-control smith movements. 3 sets of 12–20 reps with tempo 3-1-2.

Trackable outcomes: log loads, rep ranges, perceived exertion, and movement quality. Use video analysis periodically to ensure bar path alignment and joint tracking remain consistent.

Buying Guide, Best Practices, and Maintenance

Purchasing a multi functional trainer smith machine is a significant investment. Evaluate vendor reputation, warranty terms, after-sales service, and available attachments. Commercial-grade units commonly come with 5–10 year structural warranties; ensure labor and parts coverage is clearly defined. For home buyers, a 2–3 year warranty with accessible customer service is typical.

Cost considerations: entry-level home models start around $1,200–$2,000, while mid-range commercial units typically range $6,000–$15,000 depending on features and customizations. High-end integrated systems for clubs can exceed $20,000. Factor in shipping, installation, floor protection, and accessories (extra benches, plates, specialized handles).

Best practices for procurement:

- Request a factory inspection report and material certificates if buying for commercial use.

- Ask for a site visit to confirm footprint, ceiling height, and load-bearing floors.

- Purchase spare cables and commonly worn parts (pulleys, bushings) at time of sale to reduce downtime later.

- Negotiate on delivery, installation, and initial maintenance training for staff.

Buying considerations and cost analysis

Perform a simple cost-per-use analysis to justify investment. Example: a $10,000 machine used by 200 unique members per month over 5 years yields cost-per-member-per-month = $10,000 / (200 * 60) ≈ $0.83. Factor in increased membership or retention that stems from improved facility offerings to calculate ROI. Also consider the savings from consolidating multiple machines: replacing three single-purpose machines priced at $12,000 combined with a $10,000 multi functional trainer smith machine can free capital and floor space.

Financing and leasing options are common; evaluate interest rates, maintenance obligations, and tax implications. For high-traffic commercial sites, prioritize heavy-duty commercial ratings and extended warranties; the cheapest unit rarely saves money long-term.

Maintenance, troubleshooting, and case studies

Routine maintenance schedule (commercial cadence): daily visual checks, weekly lubrication of guide rods and pulleys, monthly torque checks on bolts, annual full inspection by certified technician. Simple maintenance tasks: wipe cables after heavy use, apply recommended lubricant to smith bar guide rods, and replace pulley bearings when spin smoothness degrades.

Troubleshooting common issues:

- Grinding pulleys — inspect bearings and replace worn pulleys.

- Sticky smith bar — clean guide rods and apply manufacturer-approved lubricant.

- Cable fray — immediately quarantine the unit and replace cable; do not use until fixed.

Case study: A regional physiotherapy clinic integrated a multi functional trainer smith machine and reported a 30% faster client throughput for strength rehabilitation sessions because therapists could shift quickly between low-load cable stabilization and controlled smith presses without re-rigging equipment. Their maintenance log reduced downtime by scheduling monthly inspections and holding spare cables on site.

FAQs

Q1: Is the multi functional trainer smith machine suitable for Olympic lifts? A1: Generally no — the fixed bar path and guided bearings alter the natural bar arc and balance required for cleans and snatches. Use dedicated platforms for Olympic lifts and reserve the smith and cables for accessory work and strength building.

Q2: Can beginners safely learn lifts on a smith machine? A2: Yes, the guided path provides a learning scaffold for beginners to practice pressing and squatting mechanics, but should be paired with free-weight exercises to develop stabilizer muscles.

Q3: How often should cables and pulleys be replaced? A3: Inspect cables weekly and replace at first sign of fray; pulleys often last several years but monitor for noise and resistance — replace bearings when performance drops.

Q4: What attachments are essential for versatility? A4: Adjustable bench, lat pulldown bar, row handle, ankle cuff, triceps rope, dip handles, and a landmine adapter cover most functional needs.

Q5: Are counterbalanced smith bars necessary? A5: Counterbalance aids beginners by reducing perceived bar weight and is useful for technique drills; advanced lifters often prefer full-weight bars.

Q6: How do I program for power using this machine? A6: Use dynamic effort protocols with lighter loads and higher velocities on smith explosive presses, followed by cable plyometric-style pushes or medicine ball throws for triple-extension training.

Q7: What are common safety mistakes? A7: Improperly setting safety catches, neglecting cable inspections, and loading the unit beyond rated capacity. Always confirm specifications and set catches before heavy attempts.

Q8: Can this machine replace a full rack in a commercial gym? A8: It can replace several functions but is not a direct substitute for free-weight-only racks if your clientele prioritizes maximal free-weight lifts or Olympic training. For mixed-use facilities, it often complements racks rather than replaces them.

Q9: What maintenance budget should I plan annually? A9: Commercial sites should allocate ~3–5% of equipment value annually for maintenance and parts (e.g., for a $12,000 unit, $360–$600/year) to ensure longevity and minimal downtime.