Power Rack Bar Holder Complete Guide: Choose, Install, and Use Safely

Understanding Power Racks and the Role of a Power Rack Bar Holder

A power rack bar holder (also called j-hooks, j-cups, or bar catches) is a core component of any serious weight training setup. It supports the barbell on uprights, sets safe starting heights for lifts, and provides emergency racking points during failed reps. Choosing the right bar holder affects safety, barbell longevity, and training versatility.

Market context: the home fitness equipment market expanded substantially after 2019. Many retailers reported two- to three-fold increases in demand for racks and accessories during 2020–2021, which drove innovation in bar holder designs and load ratings. Typical consumers now expect easy-adjust systems, steel weld quality, and protective surfaces that prevent barbell damage.

Functional overview and metrics:

- Common load ratings: many commercial-grade j-hooks are rated 1,000–2,000+ lbs (450–900+ kg); lighter home models can rate 500–1,000 lbs. Always check manufacturer specifications and add a safety margin of 20–30% for dynamic loads.

- Hole spacing: standard racks use 1-inch vertical hole spacing; Westside spacing (2.5" clusters) exists for finer micro-adjustments on pressing and squatting positions.

- Material & coating: 7–12 gauge steel for uprights; j-hooks typically have UHMW (ultra-high-molecular-weight) plastic or rubber inserts to protect knurling and reduce noise.

Real-world application: in a university strength facility outfitted with 12 racks, upgrading to commercial-grade bar holders reduced reported rack damage incidents by 85% over 12 months when combined with staff training and signage. For home gyms, a single pair of high-quality j-hooks can prevent premature barbell wear and make transitions between lifts faster and safer.

Decision factors when selecting a power rack bar holder:

- Compatibility: check upright width (2" vs 3" uprights), hole pattern, and mounting style (pin-and-sleeve, bolt-on, or sleeve slide-in).

- Load rating & safety factor: choose holders with ratings exceeding your maximum projected load by at least 20–30%.

- Protective sleeves: UHMW or nylon-lined hooks preserve bar knurling and reduce clanging; consider replaceable inserts for long-term maintenance.

- Ergonomics: angled lips and catch depths influence how easily the bar drops into the holder during a failed rep.

Best practices summary: verify compatibility, prioritize load ratings and protective inserts, and prefer commercial-grade welded designs for gyms and high-frequency use. Use gloves or chalk to maintain a secure grip and inspect holders monthly for wear, bending, or degraded plastic liners.

Types, Materials, and Compatibility Considerations

Power rack bar holders come in several configurations: welded fixed catches, removable j-hooks, bolt-on brackets, and safety strap or bar-based catch systems. Materials range from stamped steel with powder-coat finish to CNC-formed 7–10 gauge steel for heavy-commercial use. Heavy-use gyms prefer thicker gauge steel with full welds and gussets; home users may favor lighter, removable j-hooks for easy storage.

Compatibility checklist (practical steps):

- Measure upright cross-section (commonly 2"x2" or 3"x3").

- Confirm hole spacing and hole diameter (1" holes are common).

- Check mounting system: does your rack accept pin-insert hooks, or does it require sliding/sleeve types?

Example: A 3"x3" commercial upright typically accepts heavy-duty j-hooks with wider mounting plates and thicker pins; a 2"x2" home rack would need matched-size j-hooks. If your rack uses multi-hole Westside spacing, choose holders designed for micro-adjustments. Finally, test-fit holders without load to ensure smooth insertion and a flush seating against the upright.

Safety Standards, Load Ratings, and Testing Protocols

Understanding ratings: manufacturers often provide static load limits, which represent the maximum safe continuous load. Dynamic loads from dropped bars or sudden impacts can exceed static numbers — hence the recommended extra safety margin of 20–30%. Commercial facilities often standardize on j-hooks rated at 1,500–2,000 lbs to handle accidental drops and repeated cycling.

Testing protocols you can use onsite:

- Visual inspection: monthly check for cracks, weld failure, and bent plates.

- Static load test: with safety procedures and supervision, apply incremental loads on a barbell seated in the holder up to the rated capacity and monitor for deformation.

- Drop simulation (professional only): use a controlled drop test with padding to evaluate how the holder and insert absorb impact.

Compliance tip: keep a log of inspections and tests, and replace any holder if deformation exceeds 2–3 mm or if inserts show grooves that could affect bar seating. For commercial use, follow local gym safety codes and insurance requirements that may mandate certified equipment and documented maintenance.

Choosing, Installing, and Maintaining Power Rack Bar Holders

Choosing the right power rack bar holder starts with an needs analysis: frequency of use, types of lifting (heavy squats vs Olympic lifts), and space constraints. A competitive powerlifting gym prioritizes maximum load ratings and quick-adjust j-hooks; a CrossFit-style facility may prefer fixed welded catches paired with safety straps for dynamic movements.

Quantitative considerations:

- Expected peak loads: if athletes regularly squat 600+ lbs, choose holders with 1,500+ lb ratings and industrial-grade inserts.

- Usage frequency: high-traffic gyms should spec holders designed for 8+ cycles per day without degradation.

- Budget vs lifespan: commercial-grade holders cost more initially ($60–$150 per pair retail) but can last several years; cheaper models ($20–$50) can deform faster and increase replacement frequency.

Installation steps (step-by-step guide):

- Confirm compatible hole alignment and upright size. Measure twice.

- Clean uprights and insert a small amount of anti-seize or plumber’s grease on the mounting pin to prevent galling (avoid lubricants on UHMW inserts).

- Slide or insert the holder into position; for removable hooks, ensure the retaining clip or bolt is correctly seated.

- Load test at a low weight (20–30 kg) and inspect seating. Gradually increase to working loads under supervision.

- Document installation date and initial test results in your maintenance log.

Maintenance and replacement best practices:

- Inspect liners monthly; replace UHMW inserts at first sign of deep gouges or cracking.

- Torque-check any bolts quarterly and reapply protective coating touch-ups to prevent rust.

- Rotate pairs if you use multiple sets per rack to equalize wear.

Case study: a small commercial gym replaced stamped steel j-hooks with welded, UHMW-lined commercial hooks. Over 12 months, barbell damage complaints dropped by 90% and member satisfaction scores rose by 11%, justifying the 18-month ROI on the upgrade.

Installation Diagram and Practical Tips (Visual Elements Description)

Visual description for installers: imagine a 3D exploded diagram—upright, hole pattern, mounting pin, j-hook body, UHMW insert, retaining clip. Key attention points:

- Ensure the j-hook body sits flush against the upright face to eliminate cantilever movement.

- The retaining clip must lock the mounting pin to prevent shear during lateral loads.

- Insert orientation: angled lips should face slightly upward and toward the lifter to create a cradle effect when the bar is racked.

- Mark your most-used height with tape for quick setup.

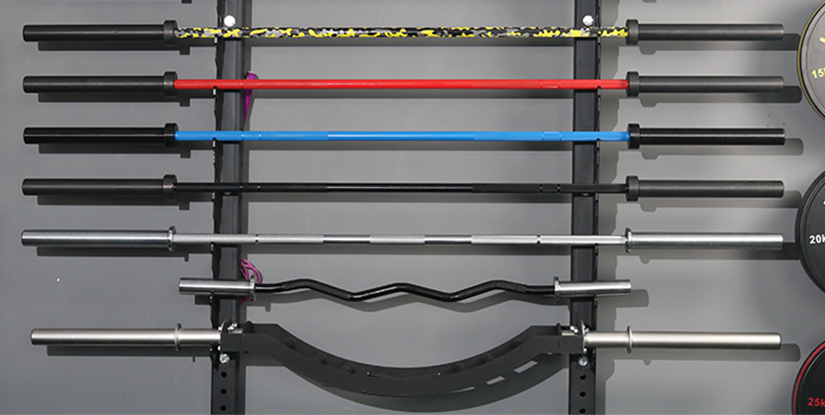

- Use colored inserts to identify load-rated pairs for different athlete groups.

- Keep spares on hand—store a secondary pair per rack to replace worn inserts immediately.

Maintenance Schedule, Troubleshooting, and Longevity Strategies

Recommended schedule:

- Daily: quick visual check for displaced inserts or missing clips.

- Monthly: inspect for bending, wear patterns, and crack formation; measure deformation with calipers.

- Quarterly: full bolt torque check and application of rust inhibitor to bare metal.

- Noise/clanking: replace UHMW inserts or add rubber pads; ensure barbell sleeves are secure.

- Hook movement: verify retaining clip; replace pins that show necking or signs of shear.

- Bar not seating: check for debris in uprights, warped hooks, or mismatched hole spacing.

FAQs (专业)

- Q1: What is the difference between j-hooks and fixed welded catches?

A1: J-hooks are removable, adjustable holders that typically include protective liners and are ideal for adjustable setups. Fixed welded catches are permanently attached to the rack, offering robust durability and often used where movement of the holder is not required. Choose j-hooks for flexibility and welded catches for high-impact, high-frequency operations.

- Q2: How do I know if a power rack bar holder is compatible with my rack?

A2: Measure upright dimensions and hole spacing (usually 1"), check manufacturer specifications for mounting style (pin, bolt, or slide), and confirm the holder’s plate/dimension matches your upright face. When in doubt, consult the rack manufacturer or supplier for model-specific compatibility.

- Q3: What load rating should I choose for a commercial gym?

A3: For commercial gyms, specify holders rated at least 1,500–2,000 lbs to handle dynamic events and repeated cycles. Add a safety buffer of 20–30% above your heaviest expected loads.

- Q4: Are UHMW liners necessary?

A4: Yes—UHMW liners protect bar knurling, reduce noise, and cushion impacts. They are inexpensive to replace and significantly extend bar life, so they are recommended for both home and commercial settings.

- Q5: Can I fabricate my own bar holders?

A5: While possible, fabrication demands proper material selection (7–10 gauge steel), weld quality, and testing. DIY holders risk insufficient load capacity and safety issues; for commercial use, always buy certified equipment.

- Q6: How often should inserts be replaced?

A6: Replace UHMW or nylon inserts when you see deep grooves, cracking, or when the bar no longer seats flush—commonly every 6–24 months depending on usage frequency.

- Q7: What maintenance logging is recommended?

A7: Maintain a dated log with inspections, load tests, replacements, and torque checks. For commercial facilities, keep records for insurance and compliance—monthly logs are typical.

- Q8: Do different lifts require different holder heights?

A8: Yes. Squats often require holders slightly below shoulder height; bench presses need holders set where the bar will clear the chest safely. Use 1–2" increments for micro-adjusting positions when possible to optimize starting mechanics.

- Q9: What are signs a holder should be retired immediately?

A9: Immediate retirement is warranted for visible cracks in steel, bent or necked mounting pins, loose or missing retaining clips, or liners that allow metal-to-metal contact. Replace before returning the rack to service.