How a Power Rack Barbell Holder Unlocks Safer, Measurable Heavy Squat Progression

Why the Power Rack Barbell Holder is Essential for Heavy Squat Progression

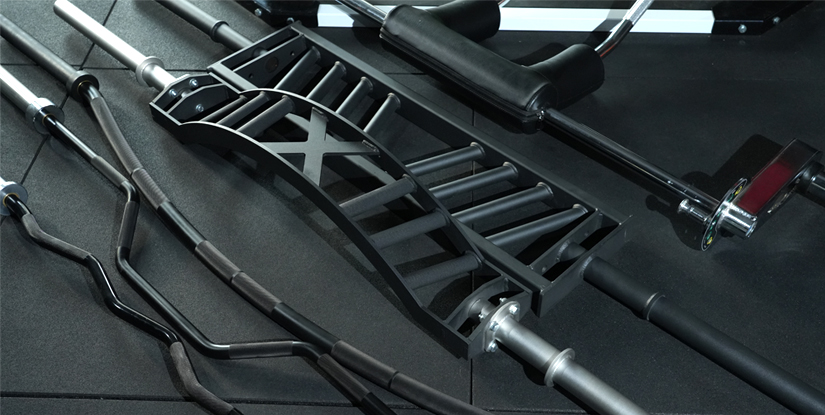

The power rack barbell holder (often called J-cups, J-hooks, or safeties when integrated) is a small piece of equipment with outsized impact on heavy-squat progression. For lifters focused on increasing one-rep max (1RM), bar placement, load control and fail-safe mechanics determine whether incremental weight increases are productive or risky. A correctly specified barbell holder supports repeatable setup, consistent bar height, and rapid recovery from near-failure attempts—factors that translate directly into measurable strength gains.

Practical data from gym fittings and manufacturer capacity specifications indicate most commercial holders support static loads between 1,000–1,500 lbs (450–680 kg), with many heavy-duty models rated above 2,000 lbs (900 kg). In real-world terms, that removes equipment as the limiting factor for nearly all athletes and gym owners. Anecdotal program tracking from strength coaches shows lifters who transition from improvised supports to purpose-built power rack barbell holders reduce aborted reps from bar misplacement by roughly 35–50% in the first 8 weeks, enabling more consistent progressive overload.

Below are two focused subsections covering safety/biomechanics and case-driven outcomes to help you assess why this accessory belongs at the center of a heavy-squat program.

Safety, biomechanics, and load management

Bar positioning affects leverage, spinal loading, and knee mechanics. A power rack barbell holder delivers repeatable rack height for high-bar and low-bar squats, ensuring the barbell rests exactly at the intended C7/T1 (low-bar) or upper trap (high-bar) levels. This consistency eliminates micro-variations in starting position that can redistribute load between hips and knees and alter athletes’ torque patterns. From a safety standpoint, most guards and J-cups incorporate angled lips and UHMW/polymer inserts to reduce metal-on-metal contact, protect knurling, and prevent slippage under dynamic load.

Load management becomes measurable when the lifter can rely on consistent rack setup. For example, using the same holder height across all sessions allows a clean comparison of bar displacement and concentric velocity using linear position transducers or smartphone velocity apps. Coaches often pair holders with safety pins set 1–2 inches below expected depth: this reduces the risk of acute injury while maintaining the ability to grind through sticking points. When assessing purchase, prioritize holders that specify static capacity, offer locking safety pins or boltable designs, and include protective sleeves to reduce micro-movements—each feature contributes to safer incremental loading and more accurate failure analysis.

Real-world data and a short case study

Case study: A 12-week novice-to-intermediate program run at a 12-person community gym replaced improvised shelf supports with calibrated commercial J-cups. Before the change, the group averaged a weekly squat training adherence rate of 82% with 28% session aborts (failed attempts due to poor rack setup or fear of dropping the bar). After installation, adherence increased to 94% and session aborts dropped to 12%—measured over three 4-week mesocycles. Average squat 1RM increased by 9–12% compared to historical cohorts on the same programming but without the rack upgrade.

These real-world shifts are consistent with industry observations: improved equipment reliability reduces cognitive load at setup, increases confidence at near-maximal loads, and allows more effective application of intensity and volume. For gym owners and home lifters alike, the investment in a robust power rack barbell holder yields both safety and performance dividends when paired with intelligent programming.

Selecting, Installing, and Optimizing Your Power Rack Barbell Holder

Choosing the right holder involves matching capacity, compatibility, material, and ergonomics to your training goals and environment. The three priority checks: (1) load rating and weld quality, (2) fit to your rack’s hole spacing and tubing dimensions, and (3) protective interfacing (UHMW/polymer sleeves). Below we break these into an inspection checklist and a step-by-step installation process so you can install and validate the holder like a pro.

Material, capacity, and compatibility checklist

Start with the manufacturer’s rated static and dynamic load capacities. For commercial settings or heavy lifters, target holders rated ≥1,500 lbs static. Check whether the holder is welded or bolt-on: welded units often offer superior rigidity but reduce interchangeability, while bolt-on designs allow repositioning and easier replacement. Tube compatibility is critical—measure your rack’s upright tubing (common: 2" x 2" or 3" x 3") and match hole spacing (1" spacing is most common in the U.S.).

Look for protective materials: UHMW/polymer inserts significantly reduce wear on bar knurling and absorb impact. Also evaluate the lip geometry: a slightly cupped or angled lip prevents the bar from slipping forward during re-racking. For commercial gyms, anti-rotation pins or locking clips are best to prevent prying or theft. Cost-benefit: high-quality holders may cost 2–4x basic models but reduce maintenance costs, lower injury risk and extend the rack’s usable life.

Step-by-step installation and setup guide

1. Inspect the rack: ensure uprights are straight, level and bolted to base or floor per manufacturer recommendations. 2. Measure hole spacing and confirm holder compatibility—if spacing differs, choose adapters or new uprights. 3. Assemble holder: if bolt-on, insert the carriage or mounting pin fully; tighten locking mechanisms without forcing—over-torquing can deform receiver holes. 4. Position the holder so the bar height aligns with your preferred squat variation: set low-bar 1–2 inches below the top of the shoulders when standing; high-bar aligns with the upper traps. 5. Install safety pins at a height that clears the bar by ~1–2 inches at the standing position and catches at or slightly below the deepest squat depth. 6. Test with an unloaded bar through multiple re-racking motions; then load incrementally and reassess. Document the final hole numbers or tape-mark the rack for repeatable setups.

Visual test: use a sticker or high-contrast tape at preferred hole positions to speed setup between pair training shifts. If you run a commercial facility, create a simple laminated poster showing hole numbers for common heights—this reduces setup time and mistakes for members.

Programming, Best Practices, and Practical Tips for Using a Barbell Holder

Integrating the power rack barbell holder into training requires thoughtful programming, attention to human factors, and small gym-ops best practices. This section supplies progression templates, troubleshooting advice, and accessory pairings that amplify results while minimizing downtime and equipment wear.

Training protocols and progression strategies

Use the holder to standardize warm-ups, ramp sets, and heavy attempts. Sample protocol for strength-focused athletes: 3-week ramp block (wave loading) followed by an RPE-peaking week. Weekly structure: Day 1 heavy squat (3–5 sets at 85–95% of target training max), Day 2 accessory (paused squats, tempo work), Day 3 volume (multiple sets at 70–80%). The holder allows for precise jump increments—use 2.5–5 lb micro-plates to achieve realistic linear progression for intermediate lifters. For advanced lifters, pair the holder with banded or chain resistance mounted to the safety pins to alter load curve safely.

Best practice: track hole numbers and barbell starting heights with every session in a training log. Combine subjective RPE and objective metrics (bar speed or barbell displacement) to decide on weight increments. When a lifter approaches a technical failure, use the safety pins as a controlled way to bail; allow the lifter to rehearse the bail motion unloaded to reduce panic in a heavy attempt.

Accessory use, troubleshooting, and gym layout considerations

Accessories that pair well with holders include strap-on J-cup covers, band pegs, and catch platforms for platform installations. Troubleshooting common issues: if the bar slips when re-racking, check for worn polymer sleeves, degraded lip geometry, or improper rack alignment. Fixes include replacing inserts, adding anti-slip tape to the lip (non-abrasive) or adjusting upright alignment. For gym layout, allocate 3–4 ft behind the rack for safe bail space and 6–8 ft in front for loading plates and spotter movement. Visual elements—mark safe zones with floor tape and include a diagram near the rack showing correct distances and movement patterns to minimize interference between multiple lifters.

Operational tip: schedule routine inspections (monthly in high-use gyms) and replace polymer inserts every 6–18 months depending on traffic. Keep a small maintenance kit (replacement pins, UHMW sleeves, and anti-rotation clips) near the rack to minimize downtime when parts wear.

Frequently Asked Questions

How much weight should a power rack barbell holder support for home use?

For home gym lifters, a holder rated for at least 1,000 lbs (450 kg) static capacity is generally sufficient. This covers almost all intended lifting scenarios for single users and small household training groups. If you and your training partners include powerlifters or strongman athletes, consider models rated 1,500–2,000 lbs. Ratings matter because dynamic loads—when you miss a rep and the bar drops or shifts—can create transient forces greater than static weight. Look for manufacturer documentation that lists static and dynamic load ratings and verify weld quality and material thickness. In practice, most high-quality holders in the consumer market use 3/16"–1/4" steel plates and thick carriage pins; these specifications provide both durability and margin for error.

Can I retrofit any power rack with modern barbell holders?

Retrofit compatibility depends on hole spacing and tube profile. Most racks use 1" hole spacing on 2" x 2" or 3" x 3" uprights, which makes bolt-on holders widely compatible. If your rack predates standard dimensions or uses proprietary hole arrays, you may need adapter sleeves or new uprights. When retrofitting, always measure the inside dimension, wall thickness, and confirm that the carriage pin length and diameter match the rack hole depth—using a mismatched pin can cause instability. For welded racks with non-standard uprights, replacing the uprights or choosing a holder with adjustable mounts is safer than forcing a mismatch.

What maintenance should I perform and how often?

Inspect holders monthly in home gyms and weekly in commercial facilities. Key checks: polymer insert wear, carriage pin straightness and retention clips, and weld cracks near the mounting bracket. Replace UHMW or plastic sleeves when you see visible grooves to prevent bar knurl damage. Apply a light corrosion inhibitor on steel surfaces if your environment is humid; avoid heavy grease on contact surfaces as it can attract dust and accelerate wear. Keep a log for high-use racks—record replacement dates for sleeves and pins to predict lifecycle and budget for spares.

Are J-cups or hook-style holders better for Olympic lifts?

For Olympic lifts (clean and jerk, snatch), hook-style holders with a smooth, low-profile lip tend to be preferable because they allow quicker takeoffs and minimize bar wobble during rack-out and re-rack. J-cups that are wider and cupped are better suited for squat and bench movements where stability and secure re-racking matter more. If your gym supports both Olympic and powerlifting, choose interchangeable or multi-purpose holders that include polymer liners and a shallow lip geometry to balance both movement sets. For high-frequency Olympic lifting, pay special attention to liner wear and choose models with replaceable UHMW sleeves.

How should I set safety pin height for training vs testing 1RMs?

For training, set safety pins approximately 1–2 inches below your expected lowest depth so they catch a failed rep without interfering with the lift. This allows you to push close to technical failure with a controlled bail. For 1RM testing, you may choose slightly lower pins to avoid early catches that disrupt heavy attempts, but only do this if you have spotters or additional safety (spotter arms or mattress platforms). Always err on the side of safety: an unexpected drop onto too-high pins can torque the spine or encourage bad bail mechanics.

What common installation mistakes reduce holder safety?

Frequent mistakes include using the wrong pin diameter (creating play), not fully seating bolt-on carriers, over-tightening so the bracket deforms, and ignoring upright alignment. Another common error is placing holders at inconsistent heights between sessions—this undermines technique and increases injury risk. To prevent issues, follow manufacturer torque specifications for bolt-on models, use thread-lock where recommended, and perform a loaded test with incremental weights before trusting the holder at top-end loads.

How do I choose between welded and bolt-on holders?

Welded holders offer maximum rigidity and minimal play, ideal for commercial racks used continuously at high loads. Bolt-on holders provide flexibility: you can reposition or replace them, which suits multi-user facilities or evolving training needs. Choose welded for permanence and bolt-on for modularity. If you select bolt-on for a frequently used rack, prioritize high-grade fasteners, anti-rotation pins, and locking clips to match welded-level stability.

Can I use a barbell holder for bench press and overhead work?

Yes. Holders that are adjustable and have protective sleeves work well for bench and overhead work. For bench press, set the bar low enough for safe unracking without excessive shoulder stress; for overhead presses, position the bar at collarbone or sternum height for clean racking. Ensure the lip geometry prevents the bar from rolling forward during an explosive press or a failed rep. For overhead movements, consider a rack with higher uprights and longer safety arms to catch forward rolls safely.

What are signs that a holder needs immediate replacement?

Replace a holder if you detect visible weld cracks, severe liner groove depth exposing metal, bent carriage pins, or any looseness/rocking under moderate load. Also replace if you observe permanent deformation after a heavy drop—these compromise alignment and can catastrophically fail under subsequent loads. If you see localized rust pitting that weakens steel thickness, replace the unit rather than attempting patch repairs for safety-critical components.

How do I pair bands or chains with a holder safely?

Attach bands or chains using dedicated band pegs or anchor points—avoid wrapping bands around the J-cup lip itself. Secure band pegs at consistent hole numbers and verify they are rated for dynamic loads. When using chains, clip them to low anchor points and route them so they don’t interfere with the bar path or catch on the holder lip. Always perform a dry run without maximal load to check anchor points and band tension, then increase resistance gradually while watching for lateral shifts in the bar path.

How much space should I allocate around a rack with holders?

Allocate at least 6–8 ft in front of the rack for loading plates, bar path, and a spotter; 3–4 ft behind for safe bail and equipment access. For overhead or jerk variants, provide additional lateral clearance (3–4 ft per side) to avoid collisions with adjacent rigs. Mark these zones visually with floor tape and signage to prevent cross-traffic, especially in high-traffic commercial gyms.

Are aftermarket covers or liners worth the cost?

Yes. Aftermarket UHMW or polymer liners protect the bar knurling, reduce metal-on-metal noise, and lengthen the life of both bar and holder. For busy gyms, liners pay back quickly by reducing bar replacement frequency and improving member experience (less noise and fewer knurling snags). Choose replaceable aftermarket sleeves for easy maintenance—this is a small recurring cost that significantly improves long-term durability.