Ultimate Guide to Choosing and Using a Power Rack with Functional Trainer

What is a power rack with functional trainer and why it matters

A power rack with functional trainer combines the vertical, heavy-load capacity of a traditional power rack with the variable-resistance, cable-driven versatility of a functional trainer. This hybrid unit is increasingly popular in home gyms, small commercial studios, and rehabilitation clinics because it supports both high-load bilateral lifts—squats, bench presses, deadlifts—and single-joint, multi-plane movements using adjustable pulleys.

Market context: the fitness equipment market has diversified toward multi-use units. More owners prioritize space efficiency and programming flexibility: a single integrated unit can replace a standalone squat rack, cable column, and several accessory stations. Typical specifications to expect include a footprint of 4–7 ft (1.2–2.1 m) width and 4–8 ft (1.2–2.4 m) depth, a 1000–1500 lb (450–680 kg) structural load rating for the rack itself, and dual cable stacks or a plate-loaded pulley system offering 100–200 lb (45–90 kg) per side.

Practical benefits:

- Space efficiency: One footprint for heavy compound lifts, cable work, pull-ups, and attachments (dip bars, landmine, band pegs).

- Training versatility: Supports powerlifting-style progression and cable-based functional training within the same session.

- Safety and progression: Integrated safety arms and adjustable J-cups allow safe heavy sets and defined progression paths.

Real-world applications include:

- Home gyms: users investing in a long-term, all-in-one solution to support strength and conditioning.

- Personal training studios: trainers program clients across strength, hypertrophy, and mobility in one station.

- Rehab settings: clinicians use adjustable pulleys for controlled eccentric/concentric work and progressive resistance.

Key decision drivers when evaluating a power rack with functional trainer include load capacity, pulley ratios, cable stack weight (if present), footprint, and accessory compatibility. Balancing these factors against budget and space yields the best long-term investment in equipment that grows with the user or facility.

Key specifications and what they mean

Understanding the numbers prevents buyer’s remorse. Here are the most important specifications and how to interpret them for real-world use:

- Load capacity (structural): Expressed in lbs or kg, this is how much weight the frame will safely support under static or dynamic loads. For heavy lifters or commercial use, aim for a minimum 1000 lb (450 kg) rating; commercial racks commonly exceed 1500 lb (680 kg).

- Cable stack weight vs. plate-loaded: Cable stacks typically range 150–200 lb (68–90 kg) per side. Plate-loaded systems use Olympic plates—advantageous for incremental loading if you already own plates. Check the pulley mechanical advantage: 2:1 ratios halve the perceived load on the stack.

- Pulley ratio and travel: A 1:1 ratio delivers direct resistance; multi-shear systems adjust force and travel—important for exercises like seated row where range matters. Pulley height adjustability should cover low, mid, and high training positions with detents every ~2–4 inches for reproducible setups.

- Accessory compatibility: Verify hole spacing (e.g., 1-inch increments), J-cup type, pull-up bar diameter, and included attachments (landmine, dip bars, lat tower). Standardized hole spacing makes aftermarket add-ons easier to integrate.

- Footprint and clearances: Allow at least 2–3 ft (60–90 cm) of clearance behind the rack for cable excursions and 8–10 ft (2.4–3 m) of ceiling height for pull-up work and oly bar overhead movements.

Tip: Request a spec sheet with bolt patterns, welding standards, and tested load ratings from the manufacturer. For commercial installs, check UL or third-party testing documentation. Visual element description: include a dimensional schematic showing height, width, depth, and pulley travel to plan room layout and floor protection.

Setting up, using, and programming: practical steps and safety

Installation and safe use are as important as selecting the right unit. Follow a step-by-step setup and operational protocol to maximize lifespan and user safety.

Step-by-step installation checklist:

- Unpack and inventory: Confirm all parts and fasteners against the manufacturer parts list.

- Position and clear flooring: Place the rack on a level surface with protective flooring (rubber tiles 6–10 mm thick for home use, 10–20 mm commercial standard). Check floor load capacity if installing on elevated surfaces.

- Assemble with torque specs: Use a torque wrench where specified; over-tightening can strip threads, under-tightening creates instability. Tighten frame bolts in a crisscross pattern.

- Anchor if required: For commercial setups or very high loads, anchor to the floor per instructions. Use chemical anchors in concrete; do not anchor to light wood or hollow tiles.

- Install cables and test travel: Run a full range-of-motion test with a light load and visually inspect pulleys and cable routing for friction or rubbing.

Daily safety routine before training:

- Inspect cables for fray and pulleys for smooth rotation.

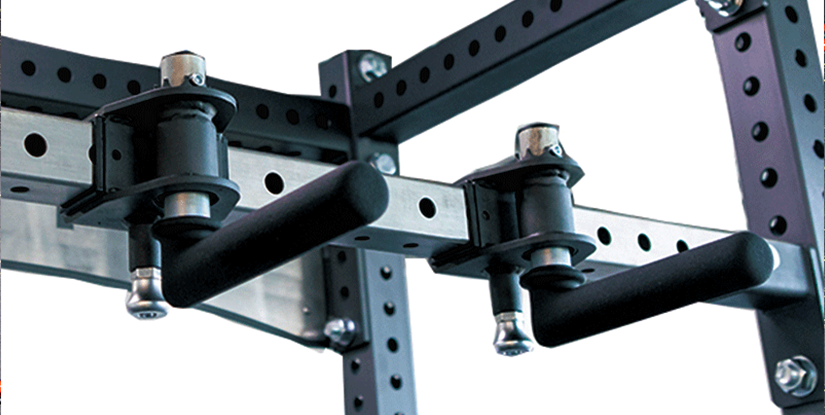

- Check J-cups and safety arms are seated and undamaged.

- Confirm pin-and-lock mechanisms are engaged; test cable stack pins for tight fit.

Programming best practices (practical):

- Combine heavy compound lifts in the rack (squat, bench, rack pulls) with cable-based accessory work (face pulls, cable rows, triceps pushdowns) to address strength and muscular balance within the same session.

- Use the functional trainer for tempo and isolation: slow 3–4 second eccentrics, controlled concentric, and varied angles to target the rotator cuff and scapular stabilizers—common weaknesses observed in lifters who only use barbells.

- Volume distribution: For strength phases, prioritize low-rep compound work (3–6 reps) and use 8–15 rep ranges with cables for hypertrophy and movement quality.

Case study (practical application): A 32-year-old recreational lifter implemented a 12-week combined program using a power rack with functional trainer. Baseline: 1RM squat 285 lb, bench 205 lb. Protocol: 3 weekly full-body sessions with one heavy day (3–5 reps), one volume day (6–10 reps), and one accessory + conditioning day (12–20 reps using cables). Result: +22 lb squat, +15 lb bench, improved shoulder health and decreased pain via targeted rotator cuff work—evidencing the value of combined heavy and cable-based accessory training.

Maintenance and longevity: checklist and tips

Routine maintenance preserves safety and reduces long-term cost. Monthly and annual checklists simplify the process.

- Monthly: Inspect cables for fraying, lubricate guide rods with silicone spray, check all fasteners for tightness, and wipe down surfaces to prevent corrosion.

- Quarterly: Inspect welding seams and powder-coating wear, replace worn pulleys, and verify pulley bearings spin freely.

- Annually: Re-torque structural bolts, replace cable housings if any signs of internal wear, and service or replace cable stacks in high-use commercial settings.

Visual element description: create a labeled maintenance diagram showing lubrication points, pulley replacement steps, and bolt locations to inspect. Practical tip: log maintenance dates and actions in a simple spreadsheet to track service intervals—this improves resale value and maintains warranty compliance.

Sample 8-week program, progression rules and tracking

This 8-week template uses the power rack with functional trainer for balanced strength and muscular development. It assumes a lifter with at least 6 months of consistent training who wants linear progression. Structure: 3 sessions per week (A/B/C), alternating heavy compound lifts in the rack with cable accessory work from the functional trainer. Keep records for sets, reps, RPE, and any technical notes.

Week structure overview:

- Week 1–3: Base phase — build volume and technique. Compound lifts at 70–80% 1RM, 3–5 sets of 3–6 reps. Cable assistance 3 sets of 8–12 reps.

- Week 4: Deload — reduce volume by 30–40% while maintaining intensity cues (use lighter loads, emphasize technique).

- Week 5–7: Intensification — increase load to 80–90% 1RM for primary lifts with lower volume (3–4 sets of 2–5 reps), increase cable intensity for hypertrophy 3–4 sets of 8–15 reps.

- Week 8: Test/Peaking — one-rep attempts if targeted, or repeat Week 4 for recovery depending on goals.

Sample Session A (Strength focus):

- Back squat (in rack): 4 sets x 5 reps @ 75% 1RM

- Bench press (in rack): 4 sets x 5 reps @ 75% 1RM

- Cable row (functional trainer, 1:1 travel): 3 sets x 10 reps

- Face pulls (high pulley): 3 sets x 15 reps

- Farmer carry or sled (optional): 2 rounds x 40 meters

Progression rules and tracking tips:

- Progress by load when you can complete all prescribed sets/reps at an RPE ≤8 for two consecutive sessions (add 2.5–5 lb upper body, 5–10 lb lower body).

- Use a simple tracking template: date, exercise, sets x reps, load, RPE, notes (e.g., bar speed, form issues). This allows objective decisions about autoregulation and deload timing.

- When accessory work stalls, manipulate volume (add a set) or reduce rest intervals rather than immediately increasing weight to protect joints.

Example metric: Track percent improvement across the cycle: if baseline 1RM squat is 300 lb and you increase training weights progressively and test at Week 8, a realistic target for intermediate lifters is a 3–8% increase (9–24 lb) depending on adherence and nutrition—use these benchmarks to evaluate equipment suitability and program effectiveness.

FAQs (专业)

Q1: Is a power rack with functional trainer suitable for commercial gym use?

A1: Yes, provided you choose a commercially rated frame (typically 11–14 gauge steel, 1500+ lb rating) and durable cable stacks or plate loading. Verify manufacturer commercial warranty and third-party test data.

Q2: What is the difference between a plate-loaded functional trainer and a stack-loaded one?

A2: Plate-loaded systems use standard Olympic plates for resistance—advantageous if you already own plates and prefer micro-loading. Stack-loaded systems offer quick weight selection with selector pins but may be limited by the stack’s maximum weight.

Q3: How much space do I need to install a hybrid unit safely?

A3: Minimum recommended is a 6 ft x 6 ft (1.8 x 1.8 m) footprint plus 2–3 ft (0.6–0.9 m) clearance around for cable travel and accessory use. Ceiling height should be at least 8–9 ft (2.4–2.7 m) for pull-ups and overhead work.

Q4: Are pulley ratios important for training outcomes?

A4: Yes. Pulley ratios affect perceived resistance and travel. A 2:1 pulley reduces load felt by the user but increases cable travel—helpful for emulating certain exercises. Confirm ratios when planning load prescriptions and selecting a machine.

Q5: What are common maintenance issues and costs?

A5: Typical issues include cable wear, pulley bearing failure, and bolt loosening. Annual maintenance is modest—expect replacement cables or pulleys every 2–5 years depending on usage; cost varies $50–300 per part for consumer units, higher for commercial-grade components.

Q6: Can I retrofit attachments later?

A6: Many manufacturers use standardized hole spacing and threaded inserts so add-ons (landmine, lat pulldown, extra handles) can be retrofitted. Confirm compatibility before purchase.

Q7: How do I calculate ROI for a small studio investing in this equipment?

A7: Calculate ROI by estimating additional revenue streams (personal training sessions, small group classes) enabled by the unit, minus acquisition and maintenance costs. Example: a $4,000 unit enabling 5 extra PT sessions/week at $50/session returns cost in ~20 weeks before maintenance—tailor the model to local pricing and utilization rates.