Complete Guide to Pull Up Bar Equipment: Selection, Installation, and Training

Understanding Pull Up Bar Equipment

Pull up bar equipment is a foundational tool for upper-body strength, core stability, and functional movement. Whether used in a commercial gym, garage, or doorway at home, a properly selected pull up bar enables progressive calisthenics, muscle-up training, and varied grip work that targets the back, shoulders, biceps, forearms, and core. Understanding the components, load ratings, and intended use scenarios is the first step toward safe and effective training.

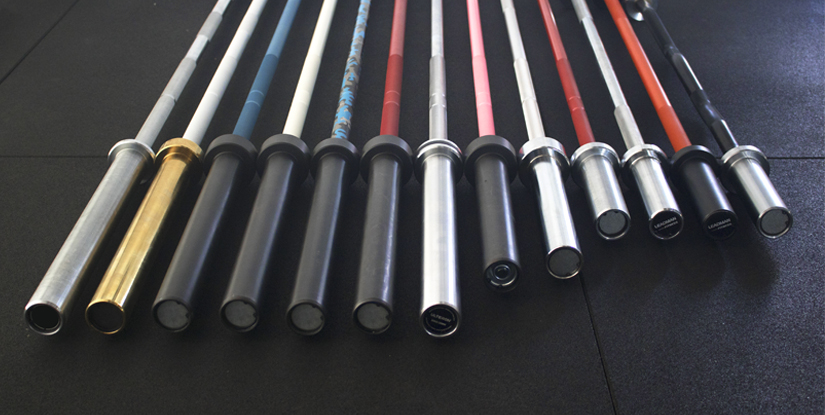

Modern pull up bars come in many forms—from freestanding rigs and wall-mounted bars to doorway and ceiling-mounted models. Each variant has trade-offs: portability versus stability, installation complexity versus range of exercises, and cost versus durability. Recognizing these trade-offs helps athletes, trainers, and home users match the equipment to their goals, space, and budget.

In practical terms, evaluate pull up bar equipment by four key attributes: maximum safe load, mounting method and surface compatibility, grip options and ergonomics, and accessory compatibility (such as dip handles, resistance band anchors, or pulley attachments). Selecting equipment that matches the intended use avoids common problems like excessive flex, installation failure, or limited exercise variety.

Types of Pull Up Bars and Where to Use Them

There are several common types of pull up bar equipment, each suited to different environments and training goals. Understanding these types helps you choose equipment that fits your space and training needs: a freestanding rig is ideal for commercial spaces and backyards; wall-mounted or ceiling-mounted bars suit permanent home gyms; doorway bars offer a temporary, space-saving solution; and modular multi-grips provide advanced athletes with varied hand positions for targeted strength work.

Key types and their best use cases include:

- Freestanding rigs and power racks: Best for cross-training, functional fitness, and multi-user gym settings. They offer high capacity, stability, and often multiple pull up stations and attachment points for rings and ropes.

- Wall-mounted bars: Suitable for permanent home or garage gyms where studs or concrete are accessible. They are low-profile, rigid, and ideal when ceiling height is limited.

- Ceiling-mounted bars: Provide more clearance and allow for kipping and muscle-up work. Require secure ceiling joists or concrete mounts and are common in dedicated training spaces.

- Doorway bars: Quick-install options for renters or small apartments. They are portable but typically limit dynamic movements and have lower load capacity.

- Adjustable and multi-grip bars: Offer neutral, wide, and narrow grips on the same unit. Great for reducing joint strain and emphasizing different muscle groups during programming.

Practical examples: a homeowner with a garage and concrete walls might choose a wall-mounted steel bar anchored with expansion bolts; an apartment dweller may use a properly fitted doorway bar for pull-ups and chin-ups but avoid kipping; a serious calisthenics practitioner will invest in a ceiling-mounted bar or freestanding rig to permit muscle-ups and bar transitions.

When selecting a type, consider the long-term training plan (static vs dynamic moves), the need for accessories (rings, bands, weights), and the environment (outdoor exposure, humidity). These specifics determine material choice (galvanized steel, powder-coated finishes) and protective measures to preserve equipment life and user safety.

Choosing and Installing Pull Up Bar Equipment

Choosing the right pull up bar equipment begins with a candid assessment of your goals, space, and structural surfaces. Define your primary use cases: rehabilitation and mobility, basic strength maintenance, weighted pull-ups, or dynamic gymnastics-style moves. This determines the required load rating and construction type. Next, audit your space for mounting points (studs, concrete walls, joists) and measure clearances—overhead space, depth from the wall, and surrounding room for kipping or swinging.

Budget considerations should account for both the purchase price and installation costs. Professional mounting may be required for ceiling or wall installations, especially when anchoring into joists or concrete. Installation quality directly affects safety; poorly anchored bars are the leading cause of equipment failure in home setups. Always match anchor hardware to the substrate and follow manufacturer torque and spacing specifications.

When comparing brands and models, look beyond aesthetics. Review rated maximum load and dynamic load certifications, material specifications (wall thickness for steel tubing), grip diameters (typically 28–34 mm for general use; larger diameters for grip strength), and warranty terms. Higher-grade finishes such as zinc or powder-coating resist rust and prolong service life in humid or outdoor conditions.

Mounting Options, Sizing, and Installation Best Practices

Installation details differ by mounting method. For wall-mounted bars, identify studs or use concrete anchors. Use a stud finder and probe to locate centerline of timber studs; prefer lag bolts through the stud rather than sheetrock-only anchors. Typical best practice for wood studs is using multiple 3/8" or 1/2" lag bolts spaced across the mounting plate and tightened to manufacturer torque specs. For concrete walls, use graded expansion anchors or sleeve anchors sized to the bar’s plate holes—follow anchor manufacturer recommendations for embedment depth.

Ceiling-mounted bars must be secured to joists or structural beams. Always verify joist orientation and spacing; mounting across two or more joists distributes load. If joists are shallow or compromised, consider adding cross-blocking or a mounting ledger to spread forces. For outdoor installations, use marine-grade hardware and seal penetrations to prevent rot or corrosion over time.

Doorway bars have their own guidelines: ensure the door frame is structurally sound, follow weight limits strictly, and avoid swinging or dynamic moves unless the product explicitly permits them. Some doorway units use tension and brackets; others compress against the frame. Inspect the frame condition—rotten or hollowed-out framing cannot reliably support load.

Specific installation tips and checks:

- Always pre-drill pilot holes for lag bolts to prevent wood splitting and ensure thread engagement.

- Use lock washers or thread-locking compound on bolts where vibration is expected (e.g., outdoor rigs).

- Confirm clearance for headroom and movement; at minimum, allow twice your arm span for dynamic exercises in a rig area.

- Torquing: follow manufacturer specs—over-tightening can strip threads or crack concrete; under-tightening reduces safety margin.

- After installation, perform a staged load test: hang with incremental weight, inspect hardware for movement, and re-torque after the first week of use.

When in doubt, consult a structural engineer or hire a certified installer. Professional assessment is especially important for ceiling mounts, outdoor rigs, and installations in older homes where joist integrity is uncertain.

Training, Programming, and Safety Using Pull Up Bar Equipment

Pull up bar equipment unlocks a wide range of training modalities—from basic strength work to complex gymnastic sequences. Effective programming balances technique, progressive overload, and recovery. For beginners, focus on building scapular control and productive movement patterns before chasing volume. For intermediate and advanced athletes, integrate grip variety, tempo variations, and weighted sets to continue driving strength adaptations.

Incorporate accessory work to address weak links: rows and face pulls for scapular strength, dead hangs and farmer carries for grip, and rotator cuff exercises to stabilize shoulders. Recovery strategies—such as mobility work, soft tissue release for the lats and forearms, and scheduled deload weeks—reduce injury risk and maintain consistent progress.

Progress tracking remains essential. Use objective metrics (reps, sets, time under tension, and added weight) and periodic testing (max unassisted reps or controlled weighted sets) to measure improvement and adjust programming. Maintain a log to identify plateaus and adapt training accordingly.

Programming Progressions, Exercises, and Recovery

Progressions provide a roadmap from unassisted attempts to advanced moves. A common beginner-to-advanced progression for pull-up strength can follow these stages: dead hang > active hang > scapular pull-ups > assisted pull-ups (band or machine) > negative eccentric pull-ups > full rigid pull-ups > weighted pull-ups > muscle-up progressions. Each stage emphasizes a key capacity—grip endurance, scapular strength, concentric power, or transition skill—and should be practiced until the movement is consistent and technically sound.

Sample exercises and programming tips:

- Dead Hang (30–90s): Build passive grip endurance and decompress the shoulders. Perform 2–3 sets at the start of sessions.

- Scapular Pull-Ups (8–12 reps): Train scapular depression and control. Keep arms straight and initiate movement from the scapulae.

- Negative Pull-Ups (3–6 reps): Slow 3–6 second descents to build eccentric strength; pair with assisted concentric reps.

- Assisted Band Pull-Ups (3–5 sets): Use appropriate band resistance to reach 6–12 reps with good form; reduce assistance gradually.

- Weighted Pull-Ups (3–5 reps): For strength, add weight with a dip belt or vest in low-rep sets.

- Muscle-Up Progressions: Combine false-grip ring work, high pulls, and transition drills; perform explosive pull-ups and dip practice on parallel bars or rings.

Weekly template (example for intermediate trainee):

- Day 1 – Strength: Weighted pull-ups 5x3, accessory rows, rotator cuff work.

- Day 2 – Volume: Multiple sets of bodyweight pull-ups 6–8 sets of 5–8, band-assisted if necessary.

- Day 3 – Skill: Muscle-up drills, false-grip holds, explosive pull-ups 4x4.

Safety considerations and maintenance: inspect grips and welds regularly, clean chalk and moisture to prevent slippage, and lubricate moving attachments as recommended. Replace worn straps, carabiners, or bolts immediately. Warm up shoulders, scapulae, and forearms before intense sessions; avoid aggressive kipping for beginners and check bar stability prior to dynamic moves.

FAQs

Q1: What load rating should I look for when buying pull up bar equipment?

A1: Choose equipment with a static load rating at least three times your bodyweight if you plan dynamic movements; for static and basic work, a twofold safety margin may suffice. Prefer certified ratings and verify whether the rating refers to static or dynamic loading.

Q2: Can I install a pull up bar on any wall?

A2: No. Install only on structural surfaces—solid studs or concrete. Avoid mounting solely into drywall. Use appropriate anchors and, if unsure, consult a professional to verify substrate capacity.

Q3: Are doorway pull up bars safe for kipping or muscle-ups?

A3: Most doorway bars are designed for static pull-ups only. Kipping and muscle-ups introduce high dynamic loads and should be executed only on bars designed and rated for such use (ceiling or rig-mounted bars).

Q4: How do I reduce shoulder strain while doing pull-ups?

A4: Prioritize scapular control with active hangs and scapular pull-ups, use neutral grips where possible, limit range or volume if painful, and incorporate rotator cuff strengthening and thoracic mobility work.

Q5: How often should I inspect and maintain pull up bar equipment?

A5: Inspect hardware monthly for rust, loose bolts, and wear. Re-torque bolts after initial installation and again after the first week of use. Replace straps and fasteners at the first sign of fraying or deformation.

Q6: What grip diameter is best for strength gains?

A6: A 28–34 mm diameter is standard for general strength training; larger diameters increase grip challenge and are used specifically for grip-strength adaptations. Choose based on specific training goals.

Q7: Can I use resistance bands with my pull up bar?

A7: Yes. Use bands for assisted pull-ups and mobility drills. Ensure bands are securely anchored and free from sharp edges. Attach bands to the bar or use a pull-up band anchor designed for the equipment to prevent slippage and damage.