How a Pull-Up Bar for Your Squat Rack Multiplies Strength Gains, Space Efficiency, and Program Variety

Why adding a pull-up bar to your squat rack multiplies training value

Adding a pull-up bar to a squat rack is one of the highest-return upgrades for home gyms and commercial facilities alike. The pull-up bar transforms a primarily vertical-loading station into a multi-plane training hub by enabling vertical and horizontal pulling, core anti-extension work, and functional movements such as toes-to-bar, muscle-ups, and band-assisted exercises. Practically speaking, a single, well-mounted pull-up bar increases exercise variety by at least 4–6 distinct movement families that complement squats, deadlifts, and presses—turning the rack from a single-purpose power tool into a full-body training anchor.

From a space-efficiency perspective, a pull-up bar leverages the existing footprint of the squat rack. Many home gyms report improved programming density: swapping one or two bulky pieces of equipment for a pull-up bar mounted to a rack increases usable exercise options without requiring extra floor area. For small gyms and garage setups, this is critical—roughly 80–90% of workouts can be completed using a squat rack plus a good pull-up bar and some small implements (bands, dumbbells, kettlebells).

Performance transfer is another major benefit. Vertical pulling enhances scapular control, posterior chain engagement, and grip strength—attributes that support heavier squats and safer deadlifts. For example, integrating weekly weighted pull-ups has been shown anecdotally in athlete programs to improve grip endurance and upper-back bracing; many strength coaches report measurable improvements in bar path stability in squat setups after 6–8 weeks of targeted pull/pull-up work. The pull-up bar also enables progressive overload in a simple and directly measurable way by adding weight via a dip belt or bands.

Key measurable attributes to evaluate when deciding to add a pull-up bar include: diameter (commonly 28–32 mm for optimal mixed grip and ring transitions), clearance height above the rack crossmember (minimum 12–18 inches for kipping and muscle-ups), and rated load capacity (quality racks commonly exceed 1000 lb / 450 kg, while a dedicated pull-up attachment often carries a 700–1000 lb / 318–450 kg rating). Choosing appropriate specs ensures the bar supports heavier athletes and dynamic movements without excessive flex.

Practical tips and quick wins:

- Start with neutral-grip training: If you’re new to pull-ups, neutral grip (parallel handles) reduces shoulder strain and helps build initial volume.

- Use bands for progressive assistance: Bands mounted from the rack allow micro-loading and high-rep work while protecting joints.

- Monitor clearance: Ensure 12–18 inches above the top of the rack to avoid head contact during kipping and complex movements.

Strength transfer and athletic carryover

Vertical pulling transfers to compound lifts by strengthening key posterior chain and scapular stabilizers. When athletes add structured pull-up variants—strict pull-ups, weighted sets, isometric holds, and eccentric emphasizes—coaches typically see improved upper-back tightness and bracing, which help maintain torso rigidity during heavy squats. A practical 8-week progression for an intermediate lifter might be: week 1–2: 3x8 band-assisted strict pull-ups; week 3–4: 4x6 strict pull-ups with added eccentric 3–4 seconds; week 5–6: 5x5 weighted pull-ups; week 7–8: mixed sets with strict + explosive reps. This progression systematically increases neural drive, hypertrophy, and tendon resilience, directly improving bar control under load.

Real-world application: a collegiate strength program recorded subjective improvements in squat depth consistency and upper-back posture in athletes who completed a twice-weekly pull-up block. While controlled studies vary, the practical evidence across gyms and teams supports pull-ups as a high-leverage accessory for compound lifts.

Space-efficiency, gym layout, and equipment economy

Integrating a pull-up bar into a squat rack reduces redundant hardware and maximizes workflow. For example, a typical garage gym with a single rack can run a full upper/lower split using the rack-mounted pull-up bar for vertical pulls, bands for assistance/resistance, and the rack itself for squats and presses. This eliminates the need for a separate power tower or lat machine. Economically, a high-quality pull-up attachment often costs 5–15% of a complete cable machine yet provides a wide range of functional movements.

Design considerations: ensure the rug or mat under the rack supports drop loads if you’ll perform weighted pull-ups or muscle-ups with fall risk; plan barbell staging so athletes can move between squats and pull-ups without interference; and keep accessory storage (bands, belts) adjacent to the rack for seamless programming.

Choosing and installing the right pull-up bar for a squat rack: specifications and step-by-step guide

Selecting the correct pull-up bar requires assessing compatibility, intended use, and safety margins. Compatibility starts with the rack’s mounting interface: many racks offer bolt-on or slide-in attachments, while others require custom welding or drilling. Confirm whether the rack’s top crossmember has pre-drilled holes or threaded inserts; if not, choose a clamp-on attachment that grips the upright without permanent modification.

Important specification checklist:

- Diameter: 28–32 mm (1.1–1.25 in) is widely used; thicker bars (35 mm) improve grip strength but may reduce repetition capacity for some athletes.

- Clearance: Minimum 12 inches of vertical clearance above the mounting point; 16–18 inches recommended for kipping and gymnastics moves.

- Load rating: Aim for a 700–1000 lb (318–450 kg) rating for commercial flexibility and safety margin.

- Finish and knurling: Powder coat or stainless steel for corrosion resistance; decide between smooth, lightly knurled, or diamond knurled surfaces depending on training needs.

Installation depends on the attachment type. Bolt-on models are most secure; clamp-on attachments are convenient but must be checked frequently for slippage. Welding is permanent and strongest but should be done by a qualified fabricator and may void rack warranties.

Materials, diameter, and mounting types explained

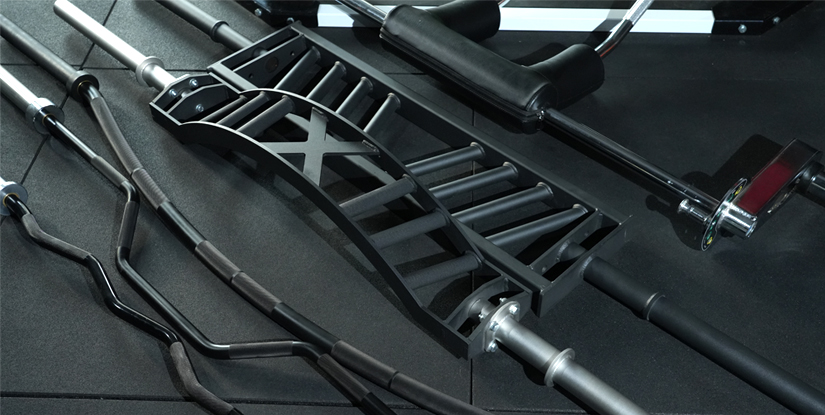

Materials range from solid steel tubing to chromed hollow tubing; solid steel reduces deflection but increases weight and cost. For home and commercial use, cold-rolled steel with a powder-coat finish balances durability and maintenance. Diameters influence hand mechanics: 28–32 mm allows mixed grip and ring-style transitions while 35 mm or thicker increases forearm recruitment and is favored in strongman-style training. Mounting types fall into three categories:

- Bolt-on: Uses rack’s threaded holes; most secure and recommended where available.

- Clamp-on: Grips the upright with mechanical clamps; requires frequent torque checks and anti-rotation measures.

- Welded: Permanent, highest strength; requires fabrication skills and can void warranties.

When choosing, check manufacturer-specified load ratings and verify hardware (grade 8 bolts preferred for heavy loads). If you plan dynamic movements (kipping, muscle-ups), prioritize bolt-on or welded mounting due to higher transient loads.

Step-by-step installation and safety checklist

Follow this procedure for a bolt-on pull-up bar attachment. Tools needed: torque wrench, grade-specified bolts, thread locker (medium strength), spirit level, measuring tape.

- Inspect rack uprights for weld integrity and pre-drilled inserts; document any cracks or deformities.

- Measure and mark the desired mounting height ensuring at least 12–18 inches of clearance above the top of the rack and allowing for athlete head clearance.

- Align the pull-up bar plate with the rack holes; hand-start bolts to ensure threading is correct.

- Tighten bolts crosswise to the manufacturer torque spec; use thread locker per instructions.

- Level the bar and torque all fasteners to spec using a calibrated torque wrench.

- Load-test with incremental weight: hang a 25 lb bag, then 100 lb, then bodyweight plus known added weight; inspect for movement or deformation.

- Perform a dynamic test—slow kipping or controlled muscle-up attempts—while spotting and observing for slippage.

Safety checklist (quick): confirm rated load > expected load + 30% safety margin, no visible deflection under static load, bolts torqued to spec, and periodic inspections scheduled every 1–3 months depending on use frequency.

Programming and practical workouts using a pull-up bar on a squat rack

A pull-up bar enables programming that complements heavy lower-body work. Balanced weekly templates combine pulling, pressing, and lower-body training to promote recovery and avoid overuse. Example split: Day A (Heavy Squat + Upper Pull), Day B (Deadlift + Horizontal Push), Day C (Accessory + Conditioning). Integrate pull-up variations on Day A and Day C to distribute volume.

Progression models include linear loading for novices and undulating periodization for intermediates. For beginners, a 3x/week approach with ascending volume works well: week 1: 3 sets of AMRAP assisted pull-ups, week 2: 4 sets, week 3: add eccentric emphasis, week 4: transition some sets to unassisted. Intermediates can cycle weighted pull-ups (5–6 sets of 3–6 reps) and hypertrophy-focused sets (4x8–12) on alternate weeks to develop both strength and size.

Examples of interval and conditioning work on the pull-up bar include EMOMs (every minute on the minute) of 6 pull-ups for 10 minutes, or ladder sets where athletes perform increasing reps up to a target and then descend. These protocols improve work capacity and grip endurance relevant to heavy lifting sessions.

Beginner-to-advanced progressions and sample microcycles

Beginner microcycle (4 weeks): Week 1: 3x6–8 band-assisted strict pull-ups twice weekly. Week 2: 4x5–7 strict pull-ups plus 2x10 negatives. Week 3: 5x4 weighted or paused chin-ups (light), plus 2x max-rep assisted. Week 4: Test max unassisted reps; adjust bands/weight accordingly. Intermediate microcycle (4 weeks): Week 1: Heavy day—5x5 weighted pull-ups; Volume day—4x8 strict. Week 2: Power day—6x3 explosive pull-ups (fast concentric); Hypertrophy day—5x10 tempo pulls. Week 3: Accumulation—6x6 with shorter rest; Week 4: Deload and test. Advanced athletes can integrate complex skill work (muscle-ups, L-sit pull-ups) and cluster sets for high tension training. Always pair heavy pulling with adequate posterior chain recovery.

Sample workouts and a short case study

Sample workout A (Strength focus):

- Back Squat: 5x5 at 80% 1RM

- Weighted Pull-Ups: 5x4 (add 5–10% bodyweight each week)

- Barbell Rows: 4x6–8

- Farmer Walks: 3x30m

- Front Squat: 4x8

- Neutral-Grip Pull-Ups: 4x10 (band-assisted if needed)

- Hanging Knee Raises: 3x12

- EMOM 10: 6 Pull-Ups

Maintenance, safety, and troubleshooting for rack-mounted pull-up bars

Maintenance routines are simple but essential. Monthly inspections should check for loose bolts, rust, paint chips, and any deformation. Wipe down knurled surfaces and remove chalk buildup to prevent corrosion. Lubricate moving clamps or pivot points per manufacturer guidance. Keep a log: date of inspection, findings, torque values, and corrective action taken.

Safety rules to enforce in any facility: always inspect the bar before dynamic use; avoid dropping from significant height where the bar, rack, or floor can be damaged; enforce maximum load limits and prohibit modified attachments that reduce rated capacity.

Common troubleshooting scenarios include lateral rotation of clamp-on bars, minor sag under heavy loads, and rubbing noises from plates. Most issues are resolved by retorquing fasteners, switching to bolt-on hardware, or adding reinforcement plates. For any visible crack in a rack upright or bar, remove the rack from service and consult a structural fabricator; do not attempt temporary repairs if load-bearing components are compromised.

Inspection checklist and load-rating verification

Use this checklist every 1–3 months (or weekly in high-use commercial settings):

- Visual inspection for cracks or weld separation around uprights and crossmembers

- Check bolt torque against manufacturer specs with a calibrated torque wrench

- Confirm no more than 3–5 mm of permanent deflection under bodyweight plus expected additional loads

- Validate manufacturer load rating label and compare to your heaviest planned load (aim for 30% safety margin)

- Inspect knurling wear and surface corrosion

Common problems and fixes

Problem: Bar rotates or slips during use. Fix: Re-torque bolts to spec, add anti-rotation welds (commercial only), or upgrade to a bolt-on attachment. Problem: Sag under load. Fix: Switch to solid steel or reduce span by using a shorter bar or reinforced crossmember. Problem: Athlete reports shoulder irritation. Fix: Reassess grip width, use neutral grip or rings, reduce volume, and ensure proper scapular mechanics are programmed.

When in doubt, consult the rack manufacturer. Avoid improvised repairs like adding sheet metal or using mismatched bolts—these introduce failure modes not considered in the original design.

FAQs

How high should a pull-up bar be mounted on a squat rack for average users?

Mount the bar so that there is at least 12–18 inches (30–45 cm) of vertical clearance between the top of the rack’s crossmember and the underside of the pull-up bar; this provides enough space for full range of motion during strict pull-ups and allows kipping or muscle-up transitions for more advanced athletes. Additionally, ensure the overall ceiling height in your space allows at least 6–8 inches of headroom beyond the top of the athlete’s reach to avoid contact during dynamic movements. For shorter athletes, you may mount slightly lower but keep sufficient clearance for full shoulder extension; for taller or dynamic users, err toward the higher end of the range. Always measure with the footwear and hairstyle the athlete will use during training to prevent surprises.

Can a clamp-on pull-up bar be as safe as a bolt-on model?

Clamp-on bars can be safe when properly installed, regularly inspected, and used within their rated loads, but bolt-on models are inherently more secure because they distribute loads through fixed threaded connections. Clamp-on attachments are convenient for modular racks or temporary setups, but they require routine torque checks and anti-rotation measures because repeated dynamic loads (kipping, muscle-ups, weighted pull-ups) can loosen clamps. If you intend to perform dynamic or heavy weighted exercises frequently, prefer bolt-on or welded attachments and ensure the hardware is high-grade (grade 8) and torqued to the manufacturer's specification.

What diameter pull-up bar is best for improving grip strength without sacrificing reps?

For a balance of grip development and repetition capacity, a diameter of 28–32 mm (about 1.1–1.25 inches) is optimal. A thinner bar favors high-rep capacity but less forearm loading; thicker bars (35 mm and above) increase grip challenge and are favored when the training goal is maximal grip strength and thick-bar adaptation. If your program includes transitions to gymnastic rings or rope climbs, 28–32 mm provides smoother carryover. Consider using interchangeable grips (fat bar handles, fat grips) when you want to vary grip stimulus without permanently changing the bar diameter.

How should I program pull-ups around heavy squat or deadlift days?

Schedule pull-up sessions to complement, not compete with, heavy lower-body loading. A common approach: pair heavy squat days with moderate-volume pulling (e.g., weighted 5x4) to exploit CNS readiness, and place high-volume or technique pull-up work on accessory or conditioning days. Ensure total weekly pull volume aligns with recovery capacity—novices typically tolerate 2–3 pull-up sessions per week, while advanced athletes may handle 3–4. Prioritize pushing maximal leg effort and follow with pulling that supports posture and grip, not exhaustive failure that undermines subsequent lower-body sessions.

Are muscle-ups safe to perform on a rack-mounted pull-up bar?

Muscle-ups can be safe if the bar and rack are rated for dynamic loads and there is sufficient clearance and floor protection. Kipping and muscle-up motions introduce higher transient loads; therefore, use a bolt-on or welded bar and inspect for lateral movement. Ensure there is at least 24 inches of unobstructed space behind the bar to prevent rack contact during transition. For facilities with unknown hardware ratings, perform progressions on gymnastics rings (which allow shoulder-friendly transitions) or on a rig specifically rated for dynamic gymnastics work.

How often should I inspect a pull-up bar and what should I look for?

Inspect the pull-up bar monthly for home use and weekly in commercial or high-traffic settings. Look for loose or corroded bolts, paint chips that reveal rust, any bending or permanent deflection, unusual noises under load, and wear on knurling or grips. Perform a light static load test (hang bodyweight and then add known increments) to reveal subtle movement. Keep a maintenance log of inspections and corrective actions; this habit prevents small issues from becoming dangerous failures.

Can I add a pull-up bar to any squat rack or are there compatibility constraints?

Most modern squat racks accommodate some form of pull-up attachment, but compatibility depends on hole spacing, upright thickness, and presence of threaded inserts. Racks with standardized hole patterns and threaded hardware are easiest to adapt with bolt-on bars. Older or custom racks may require clamp-on solutions or professional welding. Before purchase, measure upright width, hole spacing, and confirm the rack’s material and wall thickness; consult the rack manufacturer for approved attachments when possible to ensure warranty compliance and safety.

What are the best accessory attachments to pair with a pull-up bar on a squat rack?

Accessories that amplify the pull-up bar’s utility include gymnastics rings (for unilateral and transitional work), band pegs for variable resistance, dip handles, and a landmine for rotational pressing movements. A dip belt enables progressive weighted pull-ups; a set of varying-thickness bands allows graduated assistance. Storing these accessories within arm’s reach of the rack creates efficient circuits and keeps transitions fast, improving workout density and adherence. Choose accessories rated for the same load capacities as the rack to maintain overall safety.