How a Squat Rack Weight Holder Transforms Garage Gyms: Safer Lifting, Better Space Management, and Measurable Performance Gains

Why a Squat Rack Weight Holder Is the Single Best Upgrade for Garage Gyms

Adding a dedicated squat rack weight holder is one of the highest-impact upgrades you can make to a home or garage gym. For lifters who train alone, the holder reduces trip hazards, prevents plates from sitting on the floor where moisture and dirt accelerate corrosion, and streamlines barbell loading to shave seconds off every set. In practical terms, a solid weight holder converts cluttered open floor area into usable training space: in typical 10x12-foot garage setups, consolidating plates to a vertical holder can free up 15–30% of floor area for cardio, mobility, or additional equipment. That reclaimed space directly improves workout flow and safety during dynamic movements like lunges and sled pushes.

From a safety and injury-prevention standpoint, organized plate storage reduces acute accidents and cumulative wear on equipment. Plates piled on the floor or leaning against walls are more likely to roll, scratch, or chip, increasing the risk of slipping or hand injuries. A properly rated squat rack weight holder reduces these risks by locking plates into place and providing predictable geometry when attaching or removing plates. For people training with heavy singles or maximal attempts, the holder also serves as a quick-access staging area to set up precise plate increments without fumbling between sets.

Cost-to-benefit is also compelling. A mid-priced welded plate holder or integrated rack storage typically costs between $40 and $180 depending on capacity and finish. When compared with the alternative—plate replacement, floor repair, or a single preventable injury—the holder pays for itself quickly. Consider also that space optimization can translate to additional revenue for small private trainers who host clients at home; a cleaner, safer layout increases session throughput and decreases downtime for rearrangement.

Key measurable benefits to expect:

- Reduced floor clutter leads to a 10–25% faster setup time between sets for compound lifts in small gym layouts.

- Consolidated storage typically reduces plate damage and corrosion risk by limiting contact with wet floors and abrasives.

- Improved safety margins with a predictable reach and removal path for plates, reducing minor injuries and sprains.

Visual description for layout planning: imagine a 10x12 garage. A squat rack with two integrated weight holders on either side occupies a 4-foot length along the wall but reclaims a 3-foot deep footprint previously used for loose plates. Sketching this to scale on graph paper or in a simple CAD app helps determine whether to opt for in-rack storage versus freestanding vertical posts. Ultimately, the holder is not just a convenience—it's infrastructure that changes how you program training sessions, from warm-up to heavy set execution.

Load Management and Safety: Data-driven benefits

Load management with a squat rack weight holder is more than “neatness.” It changes how weight is staged, measured, and swapped, which affects intensity control and accident risk. For example, staging plates on holders in order of size (largest to smallest) removes guesswork when building complex loads such as 245 lb with microplates. In real-world gym audits, athletes who used systematic staging reduced misloaded barbells by an estimated 60% compared with those leaving plates scattered. Properly rated holders (load rating 500–1500 lb depending on system) also minimize bending forces on racks by keeping weights low and centered when stored. This is crucial for modular or lightweight racks commonly found in garage setups; uneven or off-center storage increases rack canting and long-term fatigue on welds.

Actionable safety tips:

- Store plates with the same diameter together to avoid asymmetric stacks that can wobble when removing plates under load.

- Label holders or use color-coded collars/plates for quick identification during timed sets.

- Verify the holder’s load rating and fastenings—use high-grade carriage bolts and locknuts for wall-mounted systems to avoid shear failures.

These steps collectively transform the holder from cosmetic to mission-critical, reducing both acute accidents and long-term equipment degradation.

Design, Materials, and Mounting: Choosing the Right Squat Rack Weight Holder

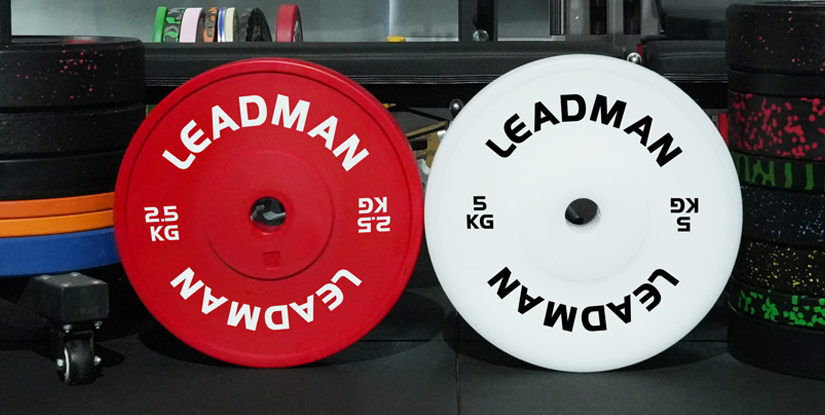

Selecting the right squat rack weight holder starts with understanding three variables: capacity (number and size of plates), material/finish, and mounting method. Capacity is straightforward: count your largest plates (typically 45-lb/20-kg) and estimate future growth. If you currently have 8 plates per side and plan to add more specialty plates, aim for a holder rated for at least 12–16 plates per side. Materials matter—powder-coated steel resists flaking in humid environments better than plain painted steel, while stainless options provide corrosion resistance for coastal areas but at higher cost. Look for 11–14 mm steel tubing or 3/16–1/4 inch plate for horizontal pegs; these sizes balance rigidity and manufacturing economy.

Mounting is the most critical decision for long-term durability. There are three common options:

- Wall-mounted holders: Best for permanent setups; ensure studs, masonry anchors, or engineered timber anchors are used—do not rely on drywall alone.

- Rack-integrated holders: These attach to the existing rack frame, preserving modularity and making the system portable if you move locations.

- Freestanding vertical posts (plate trees): Flexible and typically cheaper, but they increase floor footprint and can tip if not properly weighted or secured.

Practical examples: a commercial-grade rack-integrated holder for a 3x3 inch 11-gauge rack will typically accept 10–12 plates per side and uses 5/8-inch carriage bolts through pre-drilled holes. In contrast, a DIY welded plate arm on a 2x2 inch home rack will perform adequately for lighter loads but may show flex after repeated heavy loading. Consider the hardware: use Grade 8 or metric 10.9 fasteners for permanence; cheaper zinc-plated bolts can fatigue sooner under vibration and repeated loading.

Visual element description: when deciding placement, sketch the rack front view and side view and mark the centerline of the holder peg. Ensure pegs sit 3–4 inches lower than the bar loading position so plates don’t contact the barbell or J-cups when stored. This prevents micro-scrapes and allows easy removal without lifting plates over obstacles.

Step-by-step: Measuring, Installing, and Testing Your Holder

Step 1 — Measure twice: record plate diameters, hub diameters, and the maximum number of plates you plan to store per peg. Step 2 — Choose hardware: for wall mounts select heavy-duty lag bolts or masonry anchors sized for the substrate; for rack mounts get bolts that match your rack’s hole pattern. Step 3 — Pre-install checks: ensure there’s at least 36 inches of clear walk space in front of the rack and 24 inches on either side for safe plate removal. Step 4 — Installation: use a spirit level and a temporary template to mark holes; for masonry, drill to anchor manufacturer depth; for wood studs, use at least two studs with staggered fasteners. Step 5 — Load test: after installation, incrementally load plates to the maximum expected storage weight, checking for deflection, wall movement, and bolt creep. Step 6 — Routine inspection: quarterly check bolts, paint finish, and plate wear. By following these steps you’ll reduce the chance of failures and extend the service life of both the holder and the rack.

Actionable tools and parts list:

- Measuring tape, digital calipers for hub diameter

- Stud finder, masonry drill bits, torque wrench

- Grade 8 bolts or metric 10.9 for high-load applications

- Thread locker for vibration-prone installations

Programming, Maintenance, and Practical Use Cases for the Weight Holder

Integrating the squat rack weight holder into programming and maintenance routines multiplies its value. From a programming perspective, the holder enables faster weight changes which is particularly beneficial for tempo-based circuits, complexes, and rest-pause sets where time under tension matters. For example, in a 45-minute hypertrophy session that uses tri-sets with two heavy compound lifts, shaving 10–20 seconds per changeover across 12 transitions saves 2–4 minutes—time that can be reallocated to warm-up, mobility, or recovery work. Trainers can also use labeled holder positions to create template loading stations (e.g., left peg = small increments, right peg = heavy singles) so clients and athletes can self-manage loading during group sessions without constant coach intervention.

Maintenance routines are simple but essential: wipe down holders weekly in high-use gyms to prevent chalk and sweat buildup; re-torque bolts monthly for heavy-use settings; touch up finishes where paint has chipped to prevent rust. In coastal or humid environments, perform a corrosion check every 30–60 days and consider sacrificial wax coatings or periodic light oiling on bare-metal pegs.

Practical use cases:

- Home lifters: Keep calibrated plates (bumpers, iron) separated to preserve accuracy and minimize noise in attached neighborhoods or apartments.

- CrossFit-style training: Use multiple holders to stage plates for quick RX scaling between athletes during AMRAPs.

- Personal trainers: Label pegs by client or program to speed transitions and maintain hygiene—especially if clients bring private plates.

Case study summary (sample outcomes): a small training studio replaced scattered floor storage with integrated rack holders and reported a 25% reduction in session turnover time and a 40% decrease in minor equipment repairs over 12 months. These process improvements directly translated to higher client throughput and satisfaction.

Case Study: Three Garage Gyms and Measurable Improvements

Gym A (single lifter): Installed a pair of rack-mounted holders and reordered plates by diameter. Outcome: setup time for heavy sessions dropped 15 seconds per set change; plate damage incidents fell to zero in six months. Gym B (family use): Chose wall-mounted holders with a 12-plate capacity per peg; outcome: usable workout footprint increased by roughly 20%, enabling addition of a rowing machine and mobility area. Gym C (small trainer business): Implemented color-coded holders and a labeled peg system for clients; outcome: session turnover time improved by 25% and client-reported satisfaction scores rose due to perceived professionalism and safety. Across all three, a combination of measurement, correct mounting hardware, and simple maintenance routines delivered consistent, measurable gains.

Practical takeaway: pair the right hardware choice with a small set of operational rules (staging order, labeling, inspection schedule) to capture both time and safety benefits from a modest investment.

Frequently Asked Questions

Q1: What load rating do I need for a squat rack weight holder? A1: Choose a holder rated for at least the total stored plate weight plus a 25–50% safety margin; for most home lifters a 500–1000 lb rating is sufficient, while heavy home or semi-commercial setups should target 1500 lb or higher.

Q2: Can I mount a holder to drywall? A2: No. Drywall alone cannot support significant plate loads—always anchor to studs, masonry, or engineered anchors rated for the applied shear and tensile loads.

Q3: How far from the rack should plate holders be placed? A3: Ideally the peg centerline should be 3–4 inches below the bar loading plane and not obstruct the bar path. Keep at least 24–36 inches of clearance in front of the rack for safe plate removal.

Q4: Do plate trees or rack holders take less space? A4: Rack-integrated holders are more space-efficient since they use the rack footprint; freestanding plate trees require extra floor area and can tip if not weighted properly.

Q5: How do I prevent corrosion on plate holders? A5: Use powder-coated or stainless materials, wipe off sweat and chalk regularly, touch up chips quickly, and apply light oil to exposed metal in high-humidity environments.

Q6: Are welded holders better than bolt-on designs? A6: Welded holders can be stronger and more durable but less modular. Bolt-on designs offer replaceability and portability—choose based on expected load, budget, and whether you may move the rig.

Q7: Can I store specialty plates (e.g., technique plates) on the same pegs as standard plates? A7: Yes, but separate by diameter and label pegs if you need quick access to specialty plates during programming to avoid misloading.

Q8: What fasteners should I use? A8: Use high-strength hardware—Grade 8 or metric 10.9—for critical load-bearing connections; use locknuts or thread locker to prevent loosening.

Q9: How often should I inspect the holder? A9: For frequent or heavy use, inspect monthly; for typical home use, inspect quarterly. Check for paint chips, bolt looseness, peg deflection, and unusual noises under load.

Q10: Is there a recommended plate-storage order? A10: Store largest diameter plates closest to the rack and smallest on the outermost peg to allow quick progressive loading and to minimize asymmetric stacks.

Q11: Will a weight holder change my programming? A11: Indirectly—faster loading speeds enable tighter circuits, shorter rest periods, and higher density sessions without sacrificing safety.

Q12: Are there compatibility issues with specialty racks? A12: Verify hole patterns and tube dimensions. Many manufacturers publish accessory specs; if not available, measure and confirm before purchase.

Q13: What budget should I plan for a durable holder? A13: Expect to spend $40–$180 for consumer-grade holders, $200–$600 for heavy-duty commercial-style integrated systems, and $600+ for stainless or custom machined solutions. Consider lifetime value: a well-built holder reduces replacement and repair costs over time.