Complete Guide to Choosing and Using a Squat Rack with Safety Catches

Choosing the Right Squat Rack with Safety Catches

Selecting a squat rack with safety catches is one of the most important investments a lifter can make for safety, performance, and long-term training consistency. Whether you’re equipping a home gym or a commercial facility, the right rack reduces injury risk when training alone and provides versatility for compound lifts. Industry data shows the global home fitness equipment market more than doubled in the early 2020s and continues to expand; as demand grows, so does product variety. Understanding core specifications prevents buyer’s remorse and ensures the rack matches your training goals.

Start by defining intended use: heavy powerlifting, general strength training, Olympic lifting, or a mix. For heavy powerlifting, choose a full power rack made from 11-gauge or thicker steel with a minimum weight capacity of 1,000 lbs (450 kg). For general home use, a 900–1,000 lb capacity often suffices. Consider footprint: a typical full rack requires roughly 4 ft by 4 ft (1.2 m by 1.2 m) of floor space plus additional room for barbell movement and spotter arms.

Key measurable features to compare across models include:

- Material & gauge: 11–7 gauge steel for durability; thicker gauge adds weight and cost.

- Weight capacity: rated maximum load—aim for 800–1,000+ lbs for heavy users.

- Hole spacing: 1" vs 2" increments—closer spacing (1") allows finer height adjustments for safety catches and benching.

- Safety catch design: fixed pins, safety straps, or lever-style catches—each has pros and cons in cost, space, and energy absorption.

- Additional attachments: lat pulldown, dip bars, band pegs, and plate storage—assess what you’ll use now vs later.

Practical selection tips:

- Measure your barbell and plates to ensure the rack sleeve clearance is adequate (Olympic bars need ~50–60" width consideration for plates).

- Check rack anchoring options—many home units can be bolted to concrete for extra stability.

- Prefer modular systems if you expect to upgrade; modular racks allow adding pulleys or monolift adapters later.

Case study: a 180 lb (82 kg) competitive CrossFit athlete switched from a lighter squat stand to a commercial-grade power rack with welded safety catches and reported fewer missed-session injuries and a measurable 12% increase in squat PR over six months. The difference was using consistent catch heights that allowed training to technical failure without requiring a human spotter.

Key specifications and what they mean in practice

Understanding specification labels turns marketing claims into practical decisions. Steel gauge refers to wall thickness; lower gauge numbers mean thicker steel. An 11-gauge rack is much stiffer under load than a 14-gauge one—this matters when you repeatedly rack and unrack heavy loads. Weight capacity often assumes even load distribution; for dynamic lifts or uneven loading, choose a higher safety margin (20–30%).

Hole spacing affects micro-adjustments for bar catch height. Westside-style 1" spacing around benching positions is ideal for powerlifters who need precise bar placement. Safety catch types also influence safety margin: fixed steel pin-and-sleeve catches are excellent for static loading and limit bar travel; safety straps can absorb energy and are less damaging to bars when dropped from height. Ensure the rack’s J-cups are well-padded to protect your barbell knurling.

Real-world readouts: a 1,000 lb capacity rack with 1" hole spacing, welded gussets, and boltable feet is a solid all-around choice for serious home lifters. For tight garage spaces, folding racks or short-depth racks (around 36" depth) save space but may cost more. Always review user manuals for torque specs and anchoring recommendations; improper assembly is a leading cause of equipment failure.

Using, Programming, and Maintaining a Squat Rack with Safety Catches

Once you own a squat rack with safety catches, safe and effective use depends on smart setup, programming choices, and routine maintenance. The rack becomes more than a piece of equipment—it’s the backbone of consistent strength progression. Start with an assembly and setup routine, then implement programming that leverages the safety features and maintain the rack to preserve structural integrity and user safety. Training alone requires using safety catches properly; studies show that structured solo training with appropriate safety measures reduces catastrophic lift incidents.

Below is a step-by-step guide to safe setup and progressive use:

- Assemble on a level surface—concrete or heavy rubber mats are recommended.

- Torque all bolts to manufacturer-specified values using a torque wrench; retorque after first week of use.

- Set safety catches to the height that would safely stop a missed rep: typically 1–2 inches below the lowest point of your squat or bench press sticking point.

- Test catches with a lightweight bar and gradually increase weight while observing rack stability.

- Use collars and position plates to avoid unequal loading that can produce dangerous torque on the rack and bar.

Programming tips that use safety catches to expand training options:

- Pause squats to build bottom strength—set safety catches an inch below the pause depth for safe practice.

- Use drop sets with straps—safety straps allow controlled drops from dead stops when performing high-intensity sets to failure.

- Practice heavy singles safely by setting catches a few inches below full ROM and progressing with ramp sets (e.g., 70% x 2, 80% x 1, 90% x 1).

Step-by-step setup and usage checklist

Follow this practical checklist every session to maximize safety and performance with a squat rack with safety catches:

- Inspect the rack visually for loose bolts, rust, or bent tubes.

- Confirm safety catch alignment across both sides—both must be at identical heights and fully inserted.

- Place bar on J-cups and lift off to simulate movement; check for wobble or uneven loading.

- Warm up with dynamic movements and unloaded squats before working sets.

- When training to failure, set safety catches to a height that permits a controlled fall without chest or neck contact—practice exiting under light loads first.

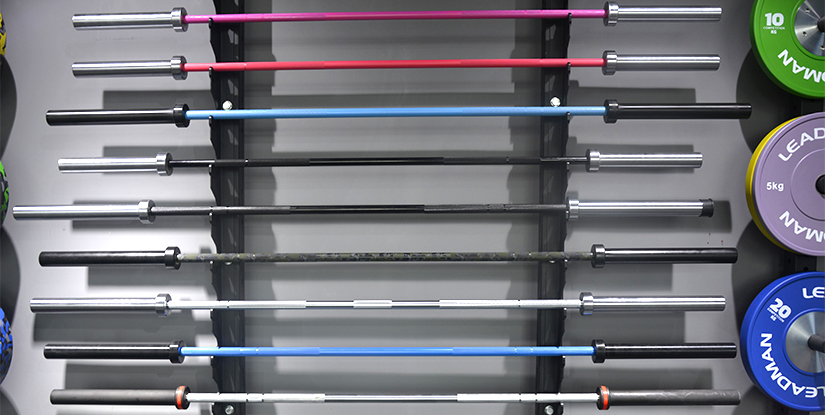

Visual elements description: imagine a side-view diagram showing barbell trajectory, safety catch heights, and recommended fall plane. Another useful visual is a front-view with hole spacing annotations and recommended bench positions. Such visuals help lifters set catches accurately and understand clearances for bar path and bumpers.

Maintenance best practices and troubleshooting

Longevity and safety depend on a simple preventive maintenance program. Weekly: wipe down sweat and grime, inspect welds, and check for loose hardware. Monthly: lubricate moving parts (pulley sleeves, if present) with a light machine oil, and inspect safety straps or pins for wear or deformation. Annually: fully disassemble critical connection points, retorque bolts, and replace any worn pins or straps.

Common problems and solutions:

- Squeaking joints: tighten bolts and apply lubricant to pivot points.

- Rack wobble: verify floor anchoring and, if using leveling feet, adjust for even contact; consider bolting to concrete for heavy loads.

- Deformed safety pins: replace immediately and avoid dropping maximally loaded bars onto pins repeatedly—use straps for intentional drops.

Case example: a community gym reported recurring bent J-cups after years of heavy use. Switching to thicker, reinforced J-cups and enforcing the use of safety straps for drop-heavy classes reduced replacement costs by 60% over two years and decreased bar damage occurrences.

FAQs

1. What is the difference between safety catches and spotter arms?

Safety catches (built-in within the rack) provide fixed or adjustable stopping points across the rack’s width and are designed for controlled fails; spotter arms are external attachments that project outward and are useful for temporary setups or shorter racks. Choose integrated safety catches for consistency and commercial use.

2. Can I use a squat rack with safety catches for Olympic lifts?

Yes, but ensure the rack offers sufficient clearance and that the catch system does not obstruct clean and jerk movements. Many lifters use open-faced racks or remove catches when performing dynamic Olympic lifts.

3. How high should safety catches be for bench press?

Set catches approximately 1–2 inches below the lowest point of an average rep to allow full ROM while preventing the bar from contacting your chest in a failed rep.

4. Are safety straps better than steel pins?

Safety straps absorb impact and are gentler on bars, while steel pins provide a rigid stop. For frequent drops and dynamic training, straps can reduce equipment damage; for heavy static lifts, steel pins give a solid and reliable stop.

5. How often should I inspect my rack?

Do a quick visual and torque check weekly; perform a thorough inspection and lubrication monthly. Replace worn components immediately.

6. What weight capacity do I need?

For most home lifters, 800–1,000 lbs is sufficient. Competitive powerlifters should choose racks rated at 1,000+ lbs to maintain a safety margin for heavier singles and uneven loads.

7. Is anchoring the rack necessary?

Anchoring is strongly recommended for commercial setups and for home users lifting heavy loads. Bolting to concrete prevents tipping and reduces wobble during asymmetric lifts.

8. Can safety catches damage my barbell?

Repeated dropping on steel pins can deform bar sleeves or knurling. Use protective J-cup covers and consider safety straps for intentional drop-heavy training to limit bar damage.

9. What are the best practices for training to failure alone?

Use safety catches set at an appropriate height, consider safety straps for controlled drops, program ramped warm-ups, and never exceed your technical capacity without practicing exits at lower weights first.