Straight Pulldown Bar: Buying Guide, Technique, Programming, and Maintenance

Choosing a Straight Pulldown Bar: Types, Materials, and Compatibility

Selecting the right straight pulldown bar starts with understanding the subtle differences in design that affect comfort, durability, and exercise outcomes. A straight pulldown bar is a fundamental cable attachment used primarily for lat pulldowns, seated rows, triceps pressdowns, and other vertical or angled pulling motions. Choosing a model that matches your training goals and equipment setup ensures safer lifts and more reliable performance over time.

Consider three primary decision areas: the bar type and shape, materials and finish, and machine compatibility including weight and attachment points. Farmers, personal trainers, and equipment buyers should examine these aspects closely because each influences grip feel, joint stress, and long-term wear.

Bar types and shapes

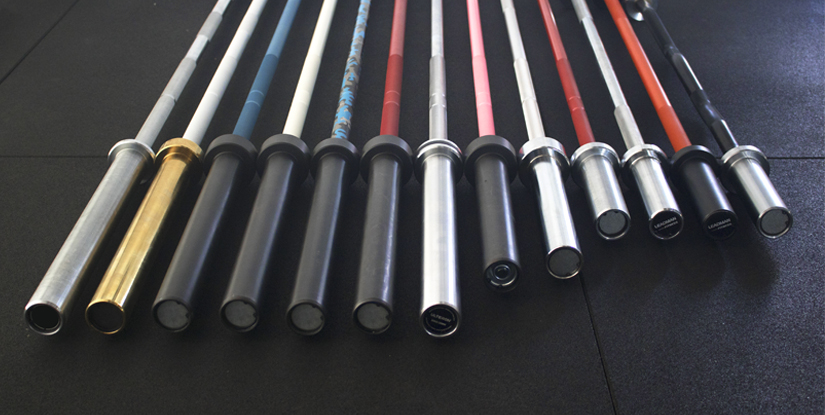

Not all straight pulldown bars are identical; variations include single-piece straight bars, slightly cambered bars, and multi-handle bars with small offsets or knurled sections. A true straight pulldown bar typically measures between 36 and 48 inches in length with a consistent diameter across the length. Shorter straight bars (24–36 inches) are more space-efficient and can be preferable for home gyms, while longer commercial bars (42–48 inches) allow for wider grip variations and greater lat engagement.

Cambered or slightly bent bars change the wrist angle and can reduce strain for lifters with shoulder or elbow issues. Multi-grip models combine straight and angled sections, offering more exercise variety without switching attachments. When selecting a type, prioritize how you plan to use it: pure lat focus benefits from a wide straight bar, while diverse cable work calls for adaptable shapes.

Materials, grip, and finish

Material choice impacts durability and feel. Most straight pulldown bars are made of solid steel — mild steel for affordability, or chrome-plated and stainless steel for corrosion resistance. Stainless steel resists rust in humid climates and commercial settings, while chrome plating offers a slick, easy-clean surface but can chip if poorly applied. For heavy daily use choose thicker steel with welded ends and a commercial-grade finish.

Grip is equally important. Knurled sections provide secure hand placement and reduce slippage with sweaty palms; look for uniform knurl patterns with rounded edges to avoid cutting into the hands. Some bars include rubber or urethane sleeves for comfort and to reduce noise when dropped or moved. Grip diameter typically ranges from 25 mm to 35 mm — thicker grips increase forearm engagement and can be beneficial for grip strength training but may be harder to hold for lifters with small hands.

Compatibility with machines and weight limits

Check attachment interface and load ratings. Most straight pulldown bars use a standard 0.5–1 inch diameter eyelet for carabiner attachment to cable machines. Verify the eyelet diameter matches your cable’s carabiner or purchase a compatible swivel attachment. Also confirm the bar’s maximum load rating — commercial-grade bars often exceed 1000 lbs static load, while consumer bars might range 300–700 lbs. While lat pulldowns rarely reach these top loads, choosing a bar with higher capacity ensures longevity and safety, especially when performing dynamic movements or drop sets.

Additionally, consider the swivel mechanism. A rotating swivel reduces torque on the cable and reduces binding during unilateral or multi-angle pulls. If your machine lacks a smooth swivel, invest in a high-quality swivel to preserve cable integrity and improve range of motion. Finally, measure clearance: ensure the bar length and your machine’s tower height allow full contraction and extension without hitting the stack or top of the cage.

Using the Straight Pulldown Bar Safely and Effectively: Technique, Programming, and Variations

Mastering the technique for the straight pulldown bar involves more than pulling weight down. Proper biomechanics protect the shoulders and neck, maximize lat activation, and translate more effectively to other pulling movements like pull-ups. A disciplined approach to rep tempo, grip width, and body position will improve muscle recruitment and reduce injury risk.

This section covers movement cues, common mistakes, detailed programming strategies tailored to goals (strength, hypertrophy, endurance), and practical exercise variations that use a straight pulldown bar to its full potential.

Proper form and common mistakes

Start with a controlled setup: sit tall on the machine, brace your core, and set your feet flat with slight posterior tilt of the pelvis. Grip the straight pulldown bar with a pronated (overhand) grip at shoulder width or slightly wider. Initiate the movement by retracting the scapulae before pulling; this cue emphasizes lat engagement rather than relying primarily on the arms.

Pull the bar down to the upper chest or just below the chin depending on your shoulder mobility. Avoid pulling behind the neck — this increases shoulder impingement risk and reduces lat activation in many lifters. Control the eccentric (return) phase for 2–3 seconds to maximize time under tension. Common mistakes include leaning excessively backward (turning the exercise into a row variation), using momentum or a jerking motion, and allowing the elbows to flare out excessively, which shifts load away from the lats to the rear deltoids.

Cues to improve form: “drive elbows into the ribcage,” “pull the elbows down and back,” and “lead with the elbows, finish with the chest.” Use lighter loads with perfect technique before adding weight to maintain joint health and muscular balance.

Programming tips and progressions

Programming with a straight pulldown bar depends on your objectives. For hypertrophy, aim for 3–5 sets of 8–15 reps with controlled eccentrics and 60–90 seconds rest. Strength-focused programs benefit from heavier loads in the 4–6 rep range for 4–6 sets, longer rest (2–3 minutes), and emphasis on maximal concentric effort. Endurance or conditioning protocols can use 2–4 sets of 15–25 reps with short rest intervals and faster but controlled tempo.

Progressive overload strategies include adding weight, increasing time under tension (slower eccentrics), increasing reps, or adding sets. Incorporate periodization: 4–6 weeks of hypertrophy followed by 3–4 weeks of strength-focused work can produce balanced gains. Unilateral variations using single-handle attachments or staggered stances help correct left-right imbalances. Use drop sets or rest-pause techniques sparingly to push past plateaus while managing recovery.

Exercise variations and practical examples

The straight pulldown bar adapts to multiple movements beyond classic lat pulldowns. Examples include:

- Close-grip pulldowns: Move hands closer to emphasize lower lats and biceps; use underhand or neutral grips where applicable.

- Tri-set back routines: Combine straight pulldowns with seated rows and face pulls to target multiple planes and scapular stabilizers.

- Triceps pushdowns: Attach the bar lower on the cable stack to perform pressdowns focusing on triceps long head engagement; modify grip width to shift emphasis.

- Straight-arm pulldowns: Keep arms extended to isolate lats and control scapular movement; useful for finishing sets.

Sample workout: 4 sets of 10 lat pulldowns (2–0–1 tempo), superset with 3 sets of 12 straight-arm pulldowns for a complete lat-focused session. For strength days: 5 sets of 5 heavy pulldowns at a controlled tempo with 2–3 minutes rest. Track progress with weekly load or rep increases and adjust accessory work (rotator cuff, scapular pull-aparts) to maintain shoulder health.

Installation, Maintenance, Troubleshooting, and Care for Your Straight Pulldown Bar

Proper installation and regular maintenance extend the life of a straight pulldown bar and keep training sessions safe. Basic care includes visual inspections, cleaning, lubrication of swivels, and timely replacement of worn components. This section outlines step-by-step installation, routine maintenance schedules, and troubleshooting common problems like swivel binding, noisy operation, and finish wear.

Whether you manage a commercial facility or a home gym, a small maintenance routine protects your investment and reduces downtime. Maintenance is straightforward but should be performed systematically: monthly for heavy-use commercial settings and quarterly for light home use.

Installation and safe setup

Begin installation by verifying component compatibility — bar eyelet must match your cable carabiner, and the cable travel should allow full range of motion without hitting the stack or frame. Use a high-quality carabiner and a rotating swivel to reduce twisting forces. For overhead towers, ensure the pulley and cable are aligned to prevent side-loading; misalignment can prematurely wear the bar eyelet and cable sheath.

Firmly secure the carabiner and perform a dry run: pull the bar through its complete range at light loads to verify smooth rotation and full clearance. Check for any play in the eyelet or excessive wobble; if present, replace the swivel or tighten fasteners. Label the bar with a maximum safe load if it will be used in a commercial environment to guide users.

Routine maintenance and troubleshooting

Cleaning: Wipe the bar weekly with a damp cloth and a mild detergent to remove sweat and oils. For knurled surfaces, use a soft-bristled brush to remove grime from grooves. Avoid abrasive chemical cleaners that strip protective finishes.

Lubrication and pivot care: Apply a light machine oil to swivels and moving hardware every 1–3 months depending on usage. If the bar begins to bind or make grinding noises, inspect the swivel for corrosion and replace if lubrication does not resolve the issue.

Addressing wear: Check for chips in chrome plating and surface rust. For minor rust, use a nylon brush and apply a rust inhibitor, then recoat with a protective spray. For deep damage or cracked welds, retire the bar and replace it — structural integrity is critical for safety. Regularly inspect the eyelet and any welded joints; fatigue cracks often start at weld seams.

FAQs

Below are 10 professional-style frequently asked questions with thorough answers addressing practical and technical aspects of straight pulldown bars.

- Q1: What grip width should I use on a straight pulldown bar?

A1: Grip width depends on training goals and shoulder health. Shoulder-width to slightly wider optimizes lat recruitment. Use a narrower grip for lower-lat emphasis and an overhand shoulder-width grip for balanced lat and upper-back work. Avoid extreme wide grips if you have limited shoulder mobility. - Q2: Can I perform behind-the-neck pulldowns with a straight bar?

A2: Behind-the-neck pulldowns increase shoulder impingement risk and are generally not recommended. Pulling to the front upper chest with controlled scapular motion is safer and more effective for lat activation. - Q3: How do I choose between chrome and stainless steel bars?

A3: Stainless steel offers superior corrosion resistance and is ideal for humid or heavy-use commercial settings. Chrome is cost-effective and offers a smooth finish but may chip over time. For longevity choose stainless or high-quality chrome with thick plating. - Q4: What is the typical lifespan of a commercial straight pulldown bar?

A4: With proper maintenance and moderate use, commercial bars can last 5–15 years. Heavy daily use in commercial gyms shortens this, making monthly inspections and timely replacement of swivels and connectors essential. - Q5: Is knurling necessary on a pulldown bar?

A5: Knurling improves grip security, especially during high-rep sets or sweaty sessions. Choose moderate knurling depth to balance grip and hand comfort; aggressive knurling can tear skin during high-volume use. - Q6: How often should swivels be lubricated?

A6: Lubricate swivels every 1–3 months in regular use. In commercial settings with constant daily use, inspect weekly and lubricate monthly. Use a light machine oil to prevent grime buildup. - Q7: Can a straight pulldown bar be used for triceps pressdowns?

A7: Yes. Position the bar on a high pulley and use a controlled wrist position to target triceps. Narrower grips emphasize medial and lateral heads, while wider grips distribute load differently along the triceps. - Q8: What should I do if my pulldown bar wobbles?

A8: Wobbling can indicate loose fasteners, a worn swivel, or a damaged eyelet. Tighten hardware first; if wobble persists, replace the swivel or retire the bar to avoid a sudden failure during lifts. - Q9: Are there ergonomic alternatives for lifters with wrist pain?

A9: Yes. Use angled attachments, neutral-grip handles, or add rubber sleeves to reduce wrist extension. Also consider reducing load, adjusting grip width, and improving form to minimize strain. - Q10: How do I test the load capacity of my straight pulldown bar?

A10: Refer to manufacturer specifications for certified load capacity. Do not perform ad-hoc load testing beyond rated limits. If no documentation exists, assume conservative loads (300–500 lbs) and prioritize visual inspections and professional replacement when in doubt.