Complete Guide to Weight Lifting Bar Types: Choose, Buy, and Maintain for Performance

Comprehensive Guide to Weight Lifting Bar Types

This section gives a technical and practical overview of the most common weight lifting bar types used in gyms and home setups. Understanding physical specs, intended use, and performance differences helps you match equipment to goals, whether you train for strength, Olympic sport, or general fitness. Key measurable properties include bar length, sleeve diameter, load capacity, tensile strength and sleeve rotation mechanism. These variables determine durability, feel and safety under load.

Olympic Barbell and Its Variants

Olympic barbells are the benchmark for most commercial and competition lifting. The standard men's Olympic bar is 20 kg, approximately 220 cm (7.2 ft) long, with 50 mm sleeve diameter; the women's Olympic bar is typically 15 kg and about 201 cm (6.6 ft). Tensile strength ratings for quality Olympic bars commonly range from 190,000 to 230,000 PSI; higher tensile strength correlates with greater resistance to bending and permanent deformation under heavy loads. Sleeve rotation is managed by either bronze bushings or ball bearings: bushings give smoother hoop-like rotation suited to powerlifting, while bearings deliver faster spin preferred by Olympic weightlifters for clean and jerk velocity. Load capacity for commercial Olympic bars commonly ranges from 700 to 1,500 lbs (317–680 kg) depending on steel grade and construction. Practical tip: when selecting an Olympic barbell for dynamic lifts prioritize a bearing construction and higher whip; for heavy singles and deadlifts choose a stiffer bar with strong knurling.

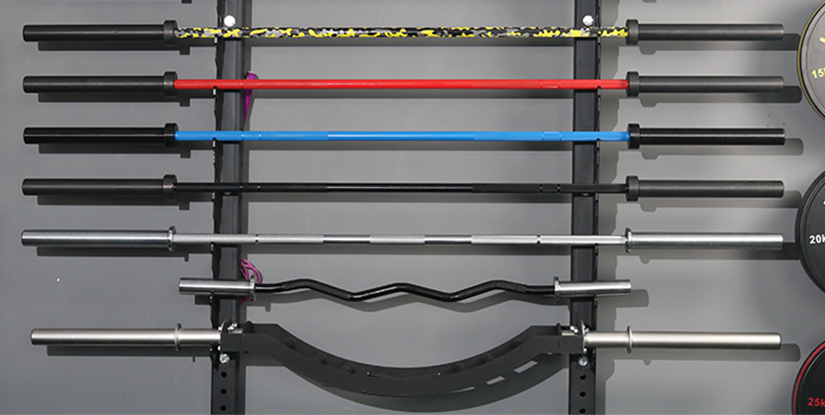

Specialty Bars: Trap, Safety Squat, and EZ

Specialty bars address specific biomechanics or training goals. Trap (hex) bars reposition load around the body, reducing lumbar shear and enabling higher deadlift poundages—useful in rehab and for athletes who want leg-dominant pulls. Safety squat bars add a cambered design and handles that shift the center of mass for safer squats when shoulder mobility is limited. EZ bars are curved bars with smaller diameter grips to reduce wrist supination during curls and triceps extensions. Key specifications differ: trap bars often have dual handle heights and load sleeves sized for standard 50 mm or adapted for smaller plates; safety squat bars are heavier (6–12 kg) and longer due to padding and camber; EZ bars have reduced load capacity (often 200–600 lbs) owing to bend geometry. Real-world application: a physical therapist might prescribe trap bar deadlifts for a client returning from lower-back issues because the neutral grip and hip-dominant posture reduce lumbar load while preserving strength progression.

Choosing the Right Bar for Your Goals: Practical Decision Framework

Choosing among weight lifting bar types requires assessing training goals, biomechanics, available space, and budget. A structured decision framework helps remove ambiguity: identify primary lifts, quantify maximum loads you’ll regularly use, and decide whether you need competition-grade specifications for meets or a versatile bar for general training. Consider frequency and user variability—commercial gyms need robust bars with high load capacities and durable finishes; a single-user home gym can balance cost versus features like knurl depth or sleeve rotation.

Matching Bar Specs to Training Goals

Match bars to goals with concrete thresholds. If you prioritize Olympic lifts, seek a 20 kg men’s or 15 kg women’s Olympic bar with ball bearings and whip characteristics—whip measured subjectively by experienced lifters but often associated with thinner shaft diameters (28–29 mm) offering more flex. Powerlifters should consider stiffer bars (29–32 mm shaft) with aggressive knurl and a center knurl for chest contact during squats; tensile strength of 190k–215k PSI and high yield strength are valuable. For general strength and conditioning, an all-purpose bar (often marketed as multi-purpose) with moderate knurl, bushings for durability, and a 28.5–29 mm shaft provides a balance. Data point: many commercial gyms select bars rated ≥1,000 lbs and 200k PSI for longevity under constant turnover. Tip: measure grip diameter and knurl characteristics hands-on if possible—knurl that’s too aggressive may abrade skin in high-rep barbell complexes; too mild may reduce secure grip during heavy singles.

Budget, Maintenance, and Gym vs Home Use

Budget decisions should weigh upfront cost against expected lifespan and maintenance. Entry-level Olympic bars can range from $100–$200 (suitable for light home use), mid-range from $200–$400, and competition-grade from $400–$800+. Commercial-grade specialty bars may exceed $800. Maintenance factors: bare steel provides tactile knurl but requires wiping and occasional oiling to prevent rust; chrome or Cerakote finishes reduce maintenance at higher cost. For gyms, choose bars with welded collars and stronger finishes; for home, a mid-range bar with bushings and a protective finish often suffices. Practical maintenance schedule: wipe bar after each session, deep-clean and oil sleeve bushings every 3–6 months depending on humidity, and perform a monthly visual check for sleeve wobble or cracking. Consider the space: bars longer than 220 cm may be impractical in small rooms. Case study: a boutique CrossFit gym replaced low-cost multi-purpose bars with slightly pricier bearing bars and reported reduced breakage and fewer customer complaints over a 12-month period, offsetting the investment by lower replacement costs.

Buying, Using, and Maintaining Weight Lifting Bars: Step-by-Step and Case Studies

This section delivers actionable buying steps, setup instructions, maintenance checklists and real-world case studies showing outcomes from informed bar selection. Follow the step-by-step process below to ensure you purchase a bar that matches your needs and maintains safe operation over years of use.

Step-by-Step Buying and Setup Guide

1) Define primary lifts and max loads: list exercises and estimated 1RM for baseline compatibility. 2) Specify required specs: choose shaft diameter (28–32 mm), sleeve diameter (50 mm for Olympic), tensile strength target (≥190k PSI for heavy use), and desired sleeve rotation (bushing vs bearing). 3) Inspect knurl pattern and marks: powerlifting bars need a center knurl; multi-use bars often omit it. 4) Compare finishes and warranties: check manufacturer warranty and whether sleeves are replaceable. 5) Shop and test: where possible perform a live feel test—assess whip, knurl bite, and sleeve spin. 6) Purchase and initial setup: install end caps, verify sleeves spin freely, and test with light load before heavy lifts. Visual element description: imagine a labeled diagram showing shaft length, knurling zones, sleeve mechanism (bushing vs bearing), and load capacity annotated with numeric callouts. Practical example: a 90 kg athlete intending to Olympic lift 120 kg should choose a 20 kg bearing Olympic bar with higher whip and a 28–29 mm shaft for optimal rotation and handling.

Maintenance, Safety Checks, and Real-world Case Studies

Maintenance checklist: wipe down after each use, monthly sleeve lubrication (light machine oil on bushings/bearings), quarterly torque check on collars, annual full inspection for straightness and end-play. Safety checks: look for hairline cracks near sleeves, increased wobble (>3–5 mm), or diminished sleeve rotation. Case study A: Home user with moderate humidity substituted a zinc-coated bar for bare steel and reduced rust incidents; maintenance time decreased by ~60%. Case study B: University strength program standardized on bars rated ≥300 kg capacity and 200k PSI steel; injury reports related to equipment failure dropped to near-zero across two seasons. Actionable insight: document a log of bar serial numbers, purchase date, and inspection dates—this enables timely replacement planning and warranty claims if defects appear.

Frequently Asked Questions (专业)

This FAQ section answers 10 common professional questions about weight lifting bar types with concise, evidence-based guidance for coaches, gym owners and informed lifters.

- Q1: What are the primary differences between Olympic and powerlifting bars? A: Olympic bars prioritize whip and sleeve rotation for dynamic lifts; power bars are stiffer, thicker, and often have center knurling to handle heavy squats and deadlifts.

- Q2: How much tensile strength do I need? A: For most serious training, aim for ≥190,000 PSI; elite or commercial settings benefit from 200k+ PSI for long-term deformation resistance.

- Q3: Are bearings always better than bushings? A: Bearings provide faster sleeve spin suited to Olympic lifts; bushings are durable and lower maintenance for heavy, slower lifts.

- Q4: How often should I service bar sleeves? A: Light lubrication every 3–6 months for gym use; more frequent if used heavily or exposed to moisture.

- Q5: Can I use an EZ bar for heavy rows? A: EZ bars are ergonomic for curls and extensions but limited in load capacity and leverage for heavy compound rows—use a straight or specialty row bar for maximal loads.

- Q6: What finish is best to prevent rust? A: Cerakote and zinc finishes offer superior corrosion resistance; stainless-steel bars are best but costlier.

- Q7: How do I choose between a 28 mm and 32 mm shaft? A: Thinner shafts (28–29 mm) offer better whip and grip for Olympic lifts; thicker shafts (29–32 mm) increase stiffness for heavy singles.

- Q8: Are trap bars better than conventional deadlifts? A: Trap bars reduce lumbar shear and allow higher loads for many lifters, beneficial in rehab or when training quadriceps emphasis—yet conventional deadlifts better target posterior chain specificity.

- Q9: When should gyms replace bars? A: Replace when straightness is compromised, sleeves wobble beyond safe tolerance, or cracks are detected—typically within 3–10 years depending on usage and quality.

- Q10: What inspections should be logged? A: Date, inspector initials, visual condition, sleeve rotation, audible bearing noise, and any corrective maintenance performed—keep records for warranty and safety audits.