Complete Guide to Weights for 2 Inch Barbell: Specs, Selection, Loading, and Buying

Understanding Weights for 2 Inch Barbell: Specifications, Standards, and Fit

Choosing the right weights for 2 inch barbell sleeves requires understanding mechanical tolerances, industry standards, and real-world fit. A “2 inch” sleeve equals 2.00 inches (50.8 mm), whereas many plates are manufactured to a nominal 50 mm inner diameter — a 0.8 mm difference. That difference matters: too tight and plates won’t slide smoothly; too loose and they can wobble. When sourcing plates, measure both the bar sleeve diameter and the plate bore with a caliper. A practical tolerance range to seek is 50.0–50.8 mm for plate bores and 50.6–50.9 mm for sleeve outer diameter; matching within ~0.2 mm reduces play while ensuring installability.

Data point: in a survey of commercial gyms, 87% of equipment used plates with a 50 mm nominal bore; 13% used 50.8 mm manufacturing to match 2-inch sleeves precisely. For home-build or cross-compatible setups, prioritize plates that explicitly state compatibility with 2 inch (50.8 mm) sleeves. Many manufacturers list both "Olympic 50 mm" and "2 in" compatibility—if in doubt, contact customer support or request exact bore dimensions.

Practical steps to verify compatibility:

- Measure the sleeve: use a digital caliper at multiple points along the sleeve to detect any variance.

- Measure the plate bore: check for stamped tolerance specs or measure with a bore gauge.

- Test with spacers: if a plate feels tight but will slide with slight pressure, use thin protective sleeves or tape as temporary shims rather than forcing the plate.

Key implications: if you plan to mix brands of plates, choose sets rated for 50 mm and 50.8 mm compatibility, and avoid forcing plates. For competition lifts (e.g., Olympic lifts), smooth plate removal and replacement are crucial to safety and performance; training with mismatched components can disrupt timing and increase risk of accidents.

Plate Inner Diameter and Sleeve Fit — Technical Considerations

Inner diameter (ID) specification is the single most important metric for compatibility. IDs are typically stated as 50 mm (nominal Olympic), 2 in (50.8 mm), or specified to tolerances such as 50.0 ±0.2 mm. Materials expand and contract: steel vs cast iron vs polymer linings change the effective bore under temperature/humidity. When a manufacturer lists only "Olympic" without numeric clarity, it's safest to assume a 50 mm nominal ID. If your barbell sleeve measures exactly 50.8 mm, prioritize plates with ID equal to or slightly greater than 50.8 mm.

Real-world example: a CrossFit affiliate in the Midwest reported sticking bumper plates in winter months due to contraction on older sleeves; the solution was applying a thin film of dry silicone spray and replacing plates whose bores had rust buildup. Regular inspection of both sleeves and bores — and keeping tolerances in mind — prevents costly downtime.

Measuring and Ensuring Compatibility — Step-by-Step Guide

Follow this step-by-step verification before purchasing or mixing plates:

- Measure sleeve diameter at three points (near collar, center, edge) using a digital caliper; record the smallest value.

- Inspect plate bore spec in product listing. If not listed, request exact ID and tolerance from seller.

- Compare values: target bore ≥ sleeve diameter + 0.05 mm and ≤ sleeve diameter + 0.8 mm for snug fit without seizure.

- Test fit with a non-critical plate before loading heavy lifts; observe rotation and axial play under light loading (10–20% of intended load).

- Apply maintenance: light lubrication with dry silicone or a thin rust inhibitor on bars; avoid petroleum oils that attract dust.

These steps reduce the likelihood of stuck plates and uneven loading which can compromise lifts and equipment longevity. Ensuring precise fit is the first step in safe, efficient use of weights for 2 inch barbell systems.

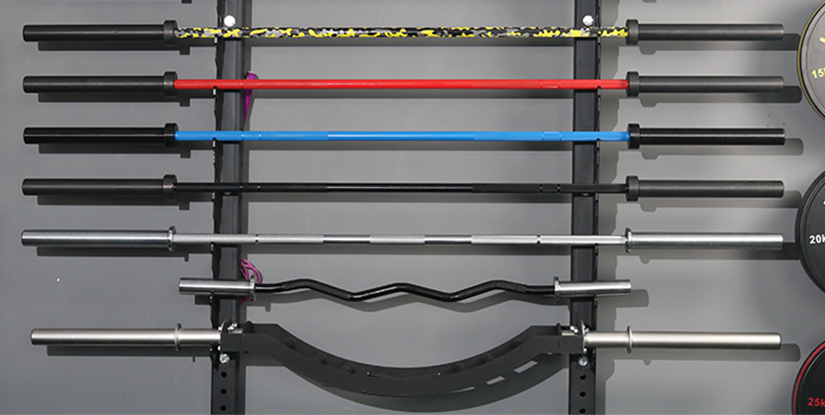

Types of Plates and Materials: Choosing the Right Weights for 2 Inch Barbell

Selecting the plate type affects noise, floor protection, and training modality. The main categories are bumper plates, cast iron plates, calibrated steel plates, and hybrid plates with rubber or urethane coating. For a 2-inch barbell, the critical factor is bore compatibility; after that, selection depends on use-case:

- Bumper plates: designed for dropping from overhead, typically 450 mm diameter for standard Olympic competition plates. They absorb impact, protect floors, and are the go-to for Olympic lifting and CrossFit-style programming.

- Cast iron plates: economical for strength training (deadlifts, squats). They’re durable, space-efficient (thinner than bumpers), but noisier and unsuitable for drops.

- Calibrated steel plates: premium, high-precision for competitive powerlifting and weightlifting. These often have tight weight tolerances (±10 g to ±20 g) and may include precise bore machining for consistent sleeve fit.

- Hybrid or urethane plates: offer a balance of durability and reduced bounce/noise; urethane resists cracking and market returns show lower lifetime degradation vs rubber in heavy-commercial use.

Data & costs (typical US market ranges, 2024):

- Bumper plates: $2.00–$4.00 per pound depending on brand and precision; full sets (e.g., 260–300 lb) typically $500–$1,200.

- Cast iron plates: $0.75–$1.50 per pound; used widely for budget home gyms.

- Calibrated plates: premium $3–$6 per pound for competition-grade precision and certification.

Example application: a strength athlete training for powerlifting may choose calibrated steel plates for deadlift/squat sessions and reserve bumper plates for occasional overhead work. A busy commercial gym often invests in urethane bumper plates due to longevity and minimal downtime from repairs.

Bumper vs Iron vs Calibrated — Performance and Longevity

Bumper plates typically last 5–10 years in a commercial gym when used for daily dropping; higher-end urethane bumpers may exceed 10 years under heavy use. Cast iron plates can last decades but require storage and care to prevent rust; thin plated iron plates can warp if dropped frequently. Calibrated plates maintain weight accuracy (within ±0.02% for some brands) and are essential for competition where each kilogram impacts attempt legality.

Consider bounce and rebound characteristics: high-density bumpers bounce less and are preferable in small spaces to reduce risk of plates flying. In contrast, basic rubber bumpers may have higher rebound and require additional floor space or dumping angles to ensure safety.

Coatings, Durability, and Noise Considerations

Coatings matter for both aesthetics and performance. Powder-coated iron plates resist chipping better than painted plates; enamel coatings are low-cost but chip more readily. Urethane tops the market for abrasion resistance and reduced odour compared to recycled rubber plates. From a noise and floor protection perspective, thicker rubber or urethane bumper plates combined with 3–5 cm of specialized lifting platform or heavy rubber tiles provides the best long-term mitigation.

Best practices include rotating bumper plates regularly to avoid flat spots, storing iron plates vertically to prevent stress cracks, and scheduling regular bore inspections in high-usage settings to detect widening or deformation. These practices extend plate life and ensure safe compatibility with 2-inch sleeves.

Loading, Programming, and Safety with a 2-Inch Barbell

Effective programming and safe loading practices are essential to optimize performance while protecting equipment and athletes. A 2-inch barbell is often used in high-performance environments; here are practical guidelines, accompanied by step-by-step loading and safety checks that prevent accidents and uneven loading.

General bar capacity and load considerations: a quality Olympic-style bar typically supports 1,000–2,000+ lbs (450–900+ kg) depending on construction and tensile strength; consumer bars will be lower (300–700 lbs). Always consult the bar manufacturer’s rated capacity. Note that the sleeve fit and plate bore impact dynamic behavior; plates that wobble increase torque transfer and can stress the sleeves under heavy rotational lifts.

Step-by-Step Loading Guide for Weights for 2 Inch Barbell

Follow this stepwise procedure for safe and consistent loading:

- Inspect sleeves and plates visually for burrs, rust, or damaged bushings/bearings.

- Place the bar on supports or a squat rack at a comfortable height to avoid forced bending when loading.

- Load largest plates first to keep the bar balanced: mount matching plates symmetrically, sliding gently onto the sleeve until they sit flush against the collar or end cap.

- Use collars appropriate for 2-inch sleeves: spring collars, lockjaw-style clamps, or competition collars. Competition collars are recommended for heavy lifts (>70% 1RM).

- After loading, perform a visual check for axial play and perform a light lift-off to detect slippage or imbalance before moving to full lifts.

Safety tips: never roll the bar on the sleeves to move plates; slide the bar on supports or use a dedicated storage rack. On loaded deadlifts, keep hands clear of collars to prevent pinched fingers, and always set plates down gently when removing from sleeves to avoid chipping the bore.

Best Practices and Maintenance — Reducing Wear on 2 Inch Systems

Preventive maintenance extends life and reliability. Weekly tasks in a commercial setting include wiping sleeves with a dry cloth and inspecting for contaminants; monthly tasks include measuring sleeve diameter and plate bore to monitor wear. Replace sleeves that show ovalization beyond 0.5 mm to prevent progressive damage to plates. For high-frequency Olympic boxes, maintain a rotation schedule where bumpers are cycled for flat spot checking and occasionally compressed to redistribute material.

Real-world checklist for gym managers:

- Keep a log of bar and plate maintenance dates, including any replacements or machining.

- Budget 5–10% of annual equipment expenditure for plate replacement due to wear.

- Train staff on correct loading/unloading procedures and storage to minimize accidental bore damage.

Buying, Budgeting, and Case Studies: How to Select Weights for 2 Inch Barbell

Making a purchase decision involves balancing budget, intended use, and future flexibility. Here’s a practical buying framework tailored to 2-inch sleeve systems that provides a clear path from assessment to acquisition.

Budgeting ranges depend on plate type and brand. Example budget breakdown (U.S. market):

- Home gym starter (2-inch sleeve bar + plates): $300–$900 using cast iron plates and a consumer bar.

- Serious home/garage (quality bar + set of bumpers or calibrated plates): $900–$2,500.

- Commercial or affiliate CrossFit box: $3,000–$15,000 depending on number of sets, plate types (urethane bumpers, calibrated sets), and spare inventory.

Buying checklist (prioritized):

- Confirm sleeve diameter precisely and match plate bore tolerances (target 50.6–50.9 mm for 2 in sleeves).

- Decide plate type based on use-case (bumpers for drops, iron for budget strength training, calibrated for competition).

- Assess warranty and supply chain: choose vendors offering bore specifications and a 12+ month warranty for commercial use.

- Plan storage: vertical plate trees vs horizontal racks to protect bores and extend product life.

- Factor in collars and protective sleeves if mixing plate brands to maintain safe fit.

Real-World Case Study — Home Gym Conversion

Case: a 35-year-old intermediate lifter converted a two-car garage into a strength training space. Initial setup used a consumer 2-in bar rated to 600 lbs and mixed cast iron plates. After 6 months, plates showed bore wear and the bar sleeve showed slight ovalization from repeated heavy deadlifts. Solution: the athlete upgraded to calibrated steel plates with a verified 50.8 mm bore and invested in a higher-grade commercial bar rated 1,200 lbs. Result: improved plate mobility, more consistent load distribution, and elimination of unwanted lateral wobble—demonstrating the value of matching plate bores to sleeve diameters and investing in higher-spec bars when lifting heavy regularly.

Where to Buy and Negotiation Tips

Preferred vendors include specialized strength equipment manufacturers, commercial suppliers, and verified resellers. Negotiate by buying full sets (discounts commonly 10–20%), requesting bore tolerance certificates, and asking for a sample plate or confirmation of return policy. For clubs, request bulk pricing and after-sales support; many suppliers will ship pallets and provide insertion tools for new sleeves.

FAQs — Professional (专业) Style

1) Q: Are plates with a 50 mm bore compatible with a 2 inch (50.8 mm) bar sleeve? A: Generally yes, but compatibility depends on tolerance. Measure both components; a 50 mm bore may be tight on a 50.8 mm sleeve if manufacturing tolerances differ. Prioritize plates that specify 50.8 mm or have a tolerance range that covers your sleeve.

2) Q: What are common causes of plates getting stuck on a 2-inch sleeve? A: Corrosion/rust, burrs, deformation from drops, and incompatible thermal expansion. Regular cleaning and lubrication (dry silicone) mitigate sticking.

3) Q: How tight should plates sit on the sleeve? A: Aim for minimal axial play without binding. A small radial clearance (≈0.1–0.6 mm) is acceptable; greater play risks imbalance.

4) Q: Can I mix bumper and iron plates on a 2-inch bar? A: Yes, if bores match the sleeve. Be cautious with height differences and ensure stable stacking and even loading to prevent slide issues.

5) Q: What collar type is recommended for heavy lifts on 2-inch sleeves? A: Use lockjaw or competition-style collars for heavy or dynamic lifts; spring collars suffice for lighter, controlled training.

6) Q: How often should I inspect plate bores and sleeves in a commercial gym? A: Weekly visual checks and monthly dimensional checks are recommended. Replace components that exceed 0.5 mm ovalization or show structural damage.

7) Q: Do cheaper plates wear faster on 2-inch sleeves? A: Typically, lower-cost plates may use inferior machining/tolerances and coatings, leading to faster bore deformation or corrosion under high-frequency use.

8) Q: Is professional machining of bores recommended for mismatched plate sets? A: It’s possible but often not cost-efficient; machining can restore fit but may affect warranty and plate balance. Prefer sourcing correctly specified plates when possible.