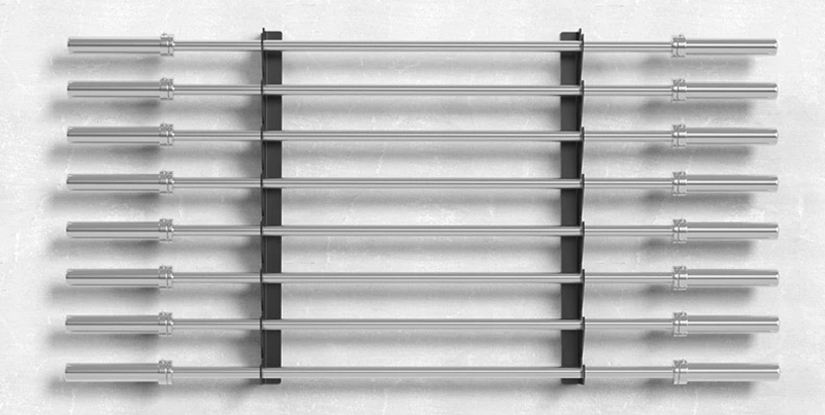

Complete Guide to Fitness Equipment: Choosing and Using Weight Bar Clamps Safely and Effectively

Overview: Fitness Equipment Safety and the Role of Weight Bar Clamps

In any strength-training environment—commercial gyms, home setups, CrossFit boxes, or physical therapy clinics—equipment safety is a foundational concern. Weight bar clamps are often underrated components that directly affect training safety, barbell performance, and workout flow. Proper clamps secure plates, reduce noise and imbalance, and prevent plate migration during dynamic lifts like cleans, snatches, and Olympic-style jerk drives.

Why focus on clamps? Small, inexpensive, and often overlooked, weight bar clamps mitigate risks that cause both acute injuries and chronic equipment wear. For example, a slipping plate during a heavy clean can alter bar path and force vectoring, which increases the chance of shoulder or lower-back strain. In addition to safety, clamps influence training efficiency: quick-change collars speed load changes in circuits and superset sessions, reducing rest time and improving metabolic stimulus.

Market data indicates a steady rise in home-gym investments since 2020; with more non-commercial users lifting at higher intensities, the demand for reliable clamps has risen proportionally. Different training populations need different solutions. Powerlifters prioritize secure, heavy-duty locking collars that eliminate movement under thousands of pounds of force, while CrossFit athletes may prefer quick, positive-locking designs that enable frequent transitions between movements.

Key benefits of quality weight bar clamps:

- Plate retention under high acceleration (clean/snatch/jerk)

- Reduced bar wobble and improved balance during unilateral or explosive lifts

- Lower noise and equipment wear from plate contact

- Faster load changes during interval-style training with quick-release models

When assessing clamps, consider: clamp type (spring, lever/lockjaw, screw-collar), material (steel, aluminum, polymer), fit (standard 28–29mm Olympic vs standard 25mm sleeves), and rated holding capacity. A practical rule: match the clamp's rated capacity and form factor to your heaviest anticipated loads and training cadence. Below we detail types, performance metrics, and tangible selection criteria.

Types of Weight Bar Clamps and Materials

There are three primary categories of weight bar clamps used across fitness settings: spring clips, lever-lock (lockjaw) collars, and screw/bolt collars. Each has strengths and trade-offs.

Spring clips are the classic, low-cost option. They are typically steel with a spring hinge and are easy to install by squeezing and pushing onto the sleeve. Pros: inexpensive, lightweight, and broadly compatible. Cons: lower rated retention under high dynamic loads; springs can fatigue over time. Manufacturers often list a holding range rather than a specific weight capacity—expect effective retention for everyday lifting up to ~150–300 lbs per side in many use-cases, but this varies.

Lever-lock or lockjaw collars use a cam mechanism and are common among Olympic lifters. They provide fast installation with a positive locking action and higher retention than basic spring clips. Many are made from aircraft-grade aluminum with rubber inserts to protect sleeves. Good lever-lock collars can handle frequent load changes and repeated impact; they’re often used in CrossFit and weightlifting settings due to speed and durability.

Screw or bolt collars (threaded collars) offer the tightest fit for maximum security. These are used where plate movement cannot be tolerated—heavy powerlifting sessions, strongman training, or plate storage. Installation is slower (screw to tighten), but they provide near-constant compression and can be rated for the heaviest loads.

Material choices matter: steel collars are robust and low-cost; aluminum collars are lighter and resist corrosion; polymer or nylon collars are quieter and gentle on bar sleeves but may deform under extreme loads. For multi-user facilities, prioritize corrosion-resistant finishes and replaceable components (springs, cam pads) to extend service life.

How to Choose the Right Weight Bar Clamps for Your Gym or Home Setup

Choosing the correct clamps requires a systematic approach. Start by cataloging your bars and plates: determine sleeve diameter (Olympic 50mm sleeves vs standard 28–29mm shaft diameters), typical load ranges, the frequency of load changes, and transport/storage needs. From there, select clamps that meet the following practical criteria:

- Compatibility: Ensure the clamp fits your sleeve diameter. Many modern Olympic bars use 50mm sleeves but have a 28–29mm shaft; universal fit isn't guaranteed.

- Retention Rating: Look for manufacturer-specified holding metrics or read user reviews reporting real-world performance under dynamic lifts.

- Speed: If you conduct high-intensity interval sessions or competitions, choose quick-release lever collars to minimize downtime.

- Durability: Prioritize materials and replaceable parts for high-traffic gyms.

- Ergonomics: Comfortable levers and easy-to-grip designs reduce installation errors and user frustration.

Step-by-step selection guide:

- Inventory your equipment—list bar model(s), sleeve diameters, and max plate loads.

- Decide on primary use—heavy, static lifts (powerlifting) versus dynamic, fast-change workouts (CrossFit/weightlifting).

- Set a budget that factors in per-pair cost and replacement frequency. Expect to pay $10–$60 per pair, depending on type and material.

- Test sample clamps on one bar: evaluate installation time, fit, noise, and perceived hold under a rehearsal set of lifts.

- Standardize across the facility to streamline maintenance and spare-part inventory.

Practical examples and real-world recommendations:

- Home lifter focused on Olympic lifts: choose aluminum lever-lock collars with rubber liners for quick changes and sleeve protection.

- Commercial gym with heavy powerlifting clientele: invest in threaded collars or heavy-duty lockjaw collars rated for higher static loads.

- Facility with mixed programming: maintain two sets—quick-lock collars for classes and threaded collars for max-effort lifts.

Procurement best practices for gyms:

- Buy clamps in pairs with matching serial numbers to avoid incompatibility.

- Keep a spare set on-site; replace springs and liners on a scheduled basis (every 6–12 months for heavy-use gyms).

- Track incidents of plate movement. If you record regular slippage events, upgrade clamp type or check bar sleeve wear.

Installation, Maintenance, and Best Practices

Proper installation and regular maintenance ensure clamps perform reliably. A step-by-step installation for common lever-lock collars:

- Confirm sleeve diameter and clear debris from sleeve surface.

- Open the lever and align the collar on the sleeve directly adjacent to the plates.

- Close the lever until it seats firmly; do not overtighten to the point of deforming plates or sleeves.

- Perform a light shake test—simulate movement to confirm no plate play.

Maintenance checklist (monthly for heavy-use gyms, quarterly for home gyms):

- Inspect for cracks, bent cams, or fatigued springs.

- Lubricate pivot points with a light machine oil for metal cams; avoid oils that attract dirt on rubber liners.

- Replace worn rubber liners or springs promptly—do not continue using compromised clamps.

- Document replacements and incidents to spot patterns (e.g., repeated liner wear on a particular bar indicates sleeve damage).

Safety tips to reduce user error:

- Train staff and members on correct installation—visual guides over racks are effective.

- Use color-coded collars for specific bars to avoid mismatches.

- Enforce a no-drop policy for collars that aren’t designed for impact; many quick-lock collars can be damaged by dropping heavy loads on the bar ends.

Training Applications, Case Studies, and Safety Protocols

Weight bar clamps are integral across a spectrum of training modalities. Below we outline practical applications, a case study from a mixed-use gym, and safety protocols supported by measurable outcomes.

Use-case examples:

- Olympic Weightlifting: Lever-lock collars that can be applied quickly between warm-up sets maintain momentum and tempo during heavy sessions.

- Powerlifting: Threaded collars used for maximal attempts ensure plate stability during slow, high-force lifts.

- Functional Fitness/CrossFit: Quick-change collars enable short transition times; durability matters due to frequent impacts.

- Rehabilitation Clinics: Lightweight polymer collars prevent damage to rehabilitative bars and allow therapists to focus on patient mechanics rather than equipment handling.

Case study — mixed-use community gym (anonymized): Over a 12-month period, a 300-member gym replaced inexpensive spring clips with lockjaw lever collars on ten Olympic bars. Key outcomes recorded:

- Plate slippage incidents dropped by 80%—from 10 recorded events across the year to 2.

- Average time between clamp replacements increased from 5 months to 14 months.

- Member-reported confidence during fast-paced classes improved in member surveys, and class throughput increased by 7% due to reduced equipment delays.

Safety protocols and checklists for facility managers:

- Pre-session: quick visual check of clamps and sleeves before peak hours.

- Post-incident: remove and tag any compromised clamp for inspection and replacement.

- Training: quarterly workshops on proper clamp use for staff; provide quick-reference cards for members.

Performance metrics worth tracking:

- Incidents of plate movement per 1,000 training hours.

- Clamp replacement frequency and cost per year.

- Member satisfaction scores related to equipment reliability.

Real-world application tip: prioritize a small inventory buffer (10–15% above active clamp count) to accommodate wear-and-tear replacements and special events. Also, invest in higher-quality clamps for bars used in competitions or high-intensity classes—this small upfront cost often reduces long-term maintenance and liability exposure.

Alternatives, Upgrades, and Future Trends

Alternatives to traditional clamps include magnetic collars, electro-mechanical locking systems (rare and pricey), and oversized storage collars for plate handling. Magnetic collars are still niche—convenient but currently limited by holding capacity and cost. For most facilities, lever-lock and threaded collars remain the gold standard.

Upgrade considerations:

- Move from spring to lever-lock for frequent dynamic workouts.

- Consider anodized aluminum lever collars for corrosion resistance and lower weight in humid environments.

- Adopt modular collars with replaceable liners and springs to minimize disposal costs.

Emerging trends include smart gym components that log bar use and detect plate movement via sensors, though these are not yet mainstream for clamps. For now, best practice is using proven mechanical solutions and robust maintenance protocols.

FAQs (专业)

- Q1: What are the safest types of weight bar clamps for heavy Olympic lifting?

A1: Lever-lock (lockjaw) collars with rubber liners are widely preferred for Olympic lifting due to their combination of fast application and strong retention. For maximal static loads, threaded collars provide the tightest fit.

- Q2: How often should I replace weight bar clamps in a commercial gym?

A2: Inspect monthly; replace springs, liners, or worn cams proactively. Typical heavy-use service life ranges from 6–18 months depending on clamp type and gym traffic.

- Q3: Can clamps damage bar sleeves?

A3: Poorly fitted or overtightened clamps can abrade or dent sleeves. Choose collars with protective liners and avoid excessive torque during installation.

- Q4: Do quick-lock collars hold as well as threaded collars?

A4: Quick-lock (lever) collars hold very well for dynamic lifts and frequent load changes, but threaded collars provide superior static compression and are preferred when plate movement must be minimized entirely.

- Q5: Are polymer collars a good option for home gyms?

A5: Yes—polymer collars are quiet, lightweight, and affordable for home use. Ensure the model you choose is rated for your heaviest loads and check for deformation under stress.

- Q6: How do I test a clamp's holding capability?

A6: Perform a practical test: secure a representative load, apply the movements typical to your training (e.g., explosive pull, drop the bar to platform), and observe plate stability. Record any slippage and replace if observed.

- Q7: What maintenance extends clamp life?

A7: Regular cleaning, lubrication of pivots (where applicable), prompt replacement of liners and springs, and avoiding dropping the bar onto collars will extend service life significantly.

- Q8: Can I mix clamp types on the same bar?

A8: Functionally yes, but consistency is recommended. Different clamp geometries can affect balance and user familiarity; standardizing simplifies training and maintenance.

- Q9: Where should gyms document clamp-related incidents?

A9: Maintain an equipment log—date, bar ID, clamp ID, description of incident, and corrective action. This data helps identify systemic issues and plan replacements.