Functional Trainer Rack: Complete Guide to Buying, Programming, and Maintaining

Introduction: Why a Functional Trainer Rack Belongs in Every Gym

A functional trainer rack is one of the most versatile pieces of fitness equipment for both commercial and home facilities. Designed around dual adjustable pulleys, integrated storage, and multiple anchor points, a functional trainer rack supports hundreds of exercises including bilateral and unilateral movements, anti-rotation drills, and sport-specific conditioning. Recent industry surveys show functional training formats are among the fastest-growing categories in boutique and full-service clubs—facilities that prioritize movement quality and client retention rely on racks to deliver measurable results.

Practical advantages include compact footprint relative to multi-station machines, scalable resistance for users from 5 kg to 200+ kg, and the ability to progress strength, power, and mobility without switching equipment. For example, a single functional trainer rack can replace a leg press, cable crossover, and smith machine stack in many programs, saving space and capital. Real-world data: a mid-size 1,200 sq ft studio that replaced three legacy machines with two racks increased usable training area by 25% while maintaining hourly throughput.

Understanding specifications matters when specifying a functional trainer rack for your facility. Key metrics to evaluate are pulley travel range, stack weight (or plate loading), carriage adjustment increments, frame load rating, and included attachments. A commercial-grade rack will typically list static load ratings of 1,000–2,000 kg for uprights and anchor points, accommodate 160–200 lb stacks (or dual 200–400 lb plate loading), and offer pulley positions in 12–20 cm increments to fine-tune line of pull. For home users, simplified racks that use band pegs and 150 lb equivalent stack systems give most of the functional benefits at lower cost and footprint.

Case study: A corporate wellness program equipped with two commercial functional trainer racks reported a 40% increase in employee participation in guided sessions and a 12-week average strength increase of 8–12% measured via normalized cable chest press and single-arm row tests. These results underscore how the right equipment choice—coupled with structured programming—drives both engagement and outcomes.

Key Components, Specifications, and Metrics

Breaking down a functional trainer rack into its components helps purchasers and trainers match equipment to needs. Core components include: two independently adjustable pulleys on vertical tracks, weight stacks or plate-loading posts, a pull-up bar or multi-grip top crossmember, storage pegs for handles and bars, and floor anchors for stability. Typical specification ranges to expect:

- Pulley height range: 10 cm above floor to 210–240 cm (adjustable in 2–10 cm steps).

- Weight stack: 70–200 lb per stack for consumer models; 160–300 lb per stack for commercial models; plate-loaded options up to 400–600 lb per side.

- Frame footprint: commercial models 1.2–2.0 m wide × 0.8–1.2 m deep; multi-rack configurations increase depth.

- Static frame load rating: 1,000–2,000 kg on commercial-grade steel.

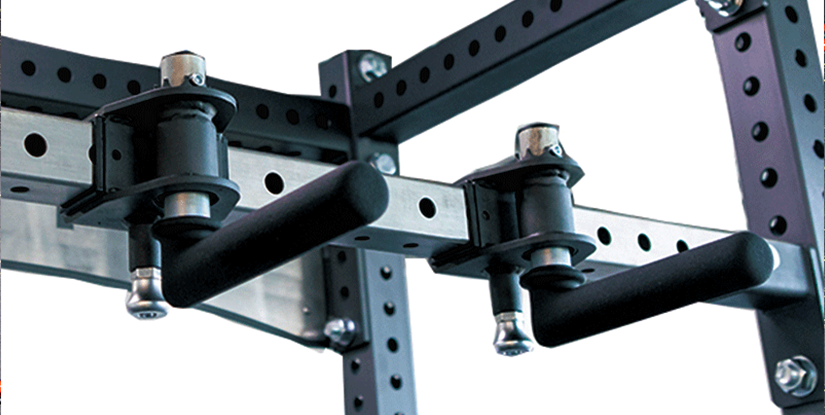

Additional features to compare: carriage locking mechanisms, low-friction pulley bearings (sealed vs exposed), included accessory kits (lat bars, ankle straps, D-handles, triceps ropes), and warranty terms. High-frequency commercial environments require sealed bearings and thicker gauge steel (10–14 mm brackets) to minimize maintenance and downtime. Visual inspection tips: look for welded gussets at high-stress junctions, powder-coat finish for corrosion resistance, and easy-access inspection plates for cable replacement.

Practical tip: measure your intended installation area and add 0.5–1.0 m clearance for cable travel and user movement. For multi-user commercial spaces, place racks back-to-back with a 1.5–2.0 m aisle to maintain safety and flow.

Programming: Designing Effective Workouts with a Functional Trainer Rack

The functional trainer rack shines for its ability to create movement-specific training plans. When programming, think first in movement patterns—push, pull, hinge, squat, rotation, and carry—then select cable angles and attachment configurations to target those patterns. Start sessions with an activation circuit (5–7 minutes) using low-load unilateral movements and anti-rotation holds; progress to strength sets, then finish with metabolic or conditioning work if desired.

Step-by-step sample session (intermediate gym-goer):

- Activation (6 minutes): banded pull-aparts, single-arm cable external rotations, hip hinge with light cable resistance—2 rounds.

- Strength (25 minutes): A1 single-arm cable chest press 4x6–8 per side (progress load 2.5–5% per week); A2 cable Romanian deadlift 4x8; rest 90s between supersets.

- Accessory (10 minutes): B1 standing single-leg cable row 3x10 per side; B2 pallof press 3x12 each side.

- Conditioning finisher (6–8 minutes): EMOM of 6: 10 cable woodchops alternating + 6 slam-cable rotations.

Programming tips with measurable outcomes:

- Use percentage-based progression for plate-loaded racks (e.g., increase 2.5–5% when form is maintained for two consecutive sessions).

- Track unilateral imbalances by measuring 1RM equivalents using submaximal testing—e.g., a 6-rep max on a single-arm cable press can estimate 1RM using the Epley formula adjusted for cable resistance curves.

- Incorporate tempo and time-under-tension variables on cable moves (e.g., 3-1-1 eccentric-pause-concentric) to emphasize hypertrophy without heavy absolute loads.

Real-world application: collegiate strength coaches often use functional trainer racks to replicate athletic positions—single-arm diagonal chops for baseball hitting velocity transfer, or split-stance cable lunges for soccer-specific acceleration. In rehabilitation settings, the adjustable line of pull lets clinicians prescribe precise ranges of motion with progressive resistance, enabling safe return-to-play protocols.

Exercise Selection, Progressions, and Testing Protocols

Exercise selection should be systematic: choose a primary movement, a posterior chain or stabilizer accessory, and a mobility or conditioning finisher. Progressions can be linear (add load each week), undulating (alternate intensity across sessions), or conjugate (rotate movements while maintaining load). Example 8-week progression for a novice-to-intermediate client focused on upper-body strength and anti-rotation control:

- Weeks 1–2: focus on technique—light loads at 60% of perceived max, 3x8–10 unilateral presses and rows, 2 pallof press sets per session.

- Weeks 3–5: load increase to 70–80% perceived max, introduce tempo work and eccentric emphasis, test 6RM at week 5 to re-calibrate loads.

- Weeks 6–8: peak weeks—work sets at 80–90% 6RM, reduce volume, perform post-cycle testing: 1) single-arm press 3RM, 2) unilateral cable row 3RM, 3) timed pallof hold for core endurance.

Testing protocols: use submaximal reps and validated prediction equations to estimate 1RM when direct maximal testing is impractical. Track improvements in absolute load, reps at a fixed load, and movement quality metrics such as deviation in trunk angle during unilateral pulls (use video for quantification).

Buying, Installing, and Maintaining Your Functional Trainer Rack

Purchasing a functional trainer rack requires balancing budget, user load, anticipated frequency, and space. Price ranges vary: consumer models suitable for home use often start at $700–$1,800, light commercial models at $2,000–$4,000, and heavy-duty commercial racks from $4,000–$10,000 depending on modular add-ons. Consider total cost of ownership—warranty terms, expected maintenance (cable replacement every 2–5 years under commercial use), and spare parts availability. A simple ROI calculation: if a rack enables an additional 3 PT sessions per week at $50 each, that’s $7,800 revenue in a year—enough to justify even a mid-tier commercial purchase.

Installation checklist and step-by-step guide:

- Site survey: measure ceiling height, floor strength, and traffic flow. Ensure 0.5–1.0 m clearance around the rack for cable travel.

- Unpack and inventory: confirm included parts (stacks, pulleys, hardware, attachments).

- Assemble on a flat surface, following torque specs in the manual; use a calibrated torque wrench for critical bolts.

- Anchor or weight the base per manufacturer guidance—commercial installations commonly require floor anchors or bolting to reinforced concrete.

- Test: run full-range pulley movement and max stack loads, inspect for cable rub, abnormal noises, and secure stops.

Maintenance schedule and best practices:

- Daily: quick wipe-down of high-touch points and handles, visual inspection of cables and carriages.

- Monthly: clean pulleys, inspect cable condition, lubricate guide rods per manufacturer spec.

- Annually: full professional inspection—replace cables every 2–5 years depending on usage, check weld integrity, replace worn bearings.

Case study: a boutique gym with 300 weekly members logged a single annual maintenance visit plus quarterly self-inspections and reduced downtime by 80% compared to peers who deferred maintenance until failure. Budget 1–2% of equipment cost annually for maintenance to maximize uptime.

Commercial vs Home Setup: Specific Considerations

Deciding between commercial and home configurations hinges on usage profile. Commercial racks are engineered for 8–12+ daily sessions and include thicker frames, dual 200+ lb stacks or plate-loading, sealed bearings, and extended warranties. Home racks prioritize compact design and value features like integrated storage and foldable pulleys. Key distinctions:

- Space and footprint: commercial: allow 2 m clearance; home: consider low-profile or single-stack models with 1.2–1.5 m footprint.

- Anchoring and flooring: commercial installations often require bolting to concrete and specialized gym flooring; home setups can use rubber tiles and weight distribution plates.

- Noise and vibration: cable systems in commercial racks reduce vibration, while budget home units can transmit more noise—important in apartment settings.

Liability and compliance: commercial facilities should implement usage policies, signage on maximum safe loads, and staff training. For home purchasers, focus on user education—include the manual, a clear progressive training program, and periodic checks of cable integrity to reduce injury risk.

FAQs

- Q: What is the primary difference between a functional trainer rack and a traditional cable crossover?

A: A functional trainer rack combines adjustable pulleys with a robust frame, storage, and usually more attachment points; it often supports plate-loading or dual weight stacks and is designed for multi-directional functional movements not just transverse cable crosses.

- Q: How much space do I need for a functional trainer rack?

A: Minimum footprint is typically 1.2 m wide × 0.8 m deep for home models; add 0.5–1.0 m clearance for cable travel and user movement. Commercial placements should plan for 1.5–2.0 m aisles between racks.

- Q: What stack weight is recommended for general fitness?

A: For most users, dual 160–200 lb stacks provide ample resistance; athletes or heavy lifters may prefer plate-loaded options allowing 400+ lb per side.

- Q: How often should I replace cables and pulleys?

A: Inspect cables monthly; replace every 2–5 years under moderate to heavy commercial use. Pulleys with sealed bearings typically last longer; replace when grinding or play is detected.

- Q: Can a functional trainer rack replace free weights?

A: It can replace many machine-based exercises and add unilateral and anti-rotation options, but free weights still excel for maximal strength lifts like heavy deadlifts and squats unless you have a plate-loaded option and rig attachments.

- Q: Is installation difficult for non-professionals?

A: Basic home models can be assembled with common tools by one or two people. Commercial installations frequently require professional installers, floor anchoring, and compliance checks.

- Q: How do I program progressive overload on a functional trainer?

A: Use small incremental loads (2.5–5%), increase reps at fixed load, manipulate tempo, and track unilateral balances. Plate-loaded racks allow precise percentage-based progressions.

- Q: What attachments should I prioritize?

A: D-handles, single-hand grips, ankle straps, triceps rope, lat bar, and a multi-grip pull-up bar are essential. Specialty attachments like rotating handles expand exercise options.

- Q: Are functional trainer racks suitable for rehabilitation?

A: Yes—adjustable pulleys allow controlled ranges, eccentric emphasis, and unilateral work that physical therapists use for progressive rehab protocols.

- Q: How much does a commercial-quality rack cost?

A: Expect $4,000–$10,000 for heavy-duty commercial racks with warranties and service agreements. Mid-range commercial units can be $2,000–$4,000.

- Q: What maintenance budget should I plan for?

A: Allocate 1–2% of equipment cost annually for parts and professional servicing; DIY maintenance reduces cost but requires knowledge.

- Q: Can I configure multiple racks together?

A: Yes—many facilities connect racks back-to-back or in linear arrays for group training; ensure structural ratings and anchoring meet manufacturer guidance.

- Q: How do I select between cable stacks and plate-loaded options?

A: Choose cable stacks for simplicity and quick load changes in busy studios; select plate-loaded models when you need higher top-end resistance and more precise incremental loading for athletes.