How to Make Fitness Equipment Glide

Understanding Glide Mechanics for Fitness Equipment

Gliding motion in fitness equipment hinges on reducing friction between moving parts while maintaining strength, safety, and durability. In commercial and home gyms alike, glide improves user experience, reduces effort, and extends equipment life. A well designed glide system considers contact surface materials, lubrication, bearing choice, and alignment. This section demystifies the physics of glide and maps it to practical hardware decisions you can implement in existing machines or during new builds.

Friction is not a single number; it is a family of phenomena that depends on surface roughness, load, speed, lubrication, and temperature. The Stribeck curve, describing how friction transitions from boundary to mixed to hydrodynamic regimes, helps explain why a dry contact often performs worse than a lubricated one at typical gym speeds. For equipment that moves under heavy user loads, you want a surface pair that yields low friction at the operating range while staying robust against wear. Guidance below uses real world data ranges you can compare against your designs or retrofit projects.

In practice, you can observe glide performance across three layers: surface chemistry, mechanical support, and assembly quality. Surface chemistry refers to the actual contact materials and any coatings or liners. Mechanical support covers bearing types, rails, wheels, and rollers. Assembly quality includes alignment, clearances, and mounting rigidity. Each layer contributes to total friction and stability, so a holistic approach yields the best results.

Practical tips to start include a quick audit of existing equipment: identify every sliding or rolling surface, note materials, measure play, and listen for rubbing or squeaks. A small, iterative approach—starting with one glide path and testing with controlled loads—often delivers the clearest ROI before a full retrofit.

Realistic planning also means considering maintenance and operating environment. Temperature swings in a gym, dust exposure, and cleaning agents can alter lubricant performance or wear rates. A glide system designed for easy maintenance will preserve friction reduction over time, reducing downtime and preserving user satisfaction.

Key takeaway: glide is the sum of materials, lubrication, bearings, and precision assembly. If one element underperforms, the entire system suffers. The following sections translate this concept into actionable design and retrofit steps you can apply today.

1.1 Friction Fundamentals: Material Science and Coefficients

Surface pairing determines the baseline friction coefficient. Typical ranges you may encounter in fitness equipment include:

- PTFE liners on steel or aluminum: 0.04 to 0.20 depending on load and temperature

- Polymer bushings on metal: 0.15 to 0.40 in dry conditions

- Urethane or nylon wheels on steel rails: 0.25 to 0.65 when dry

- Rolling bearings (ball or roller) with proper lubrication: dynamic friction 0.001 to 0.005

In many gym applications the gliding element is a carriage or sled that travels along a rail. Converting from a high friction state to a low friction state often yields a 30 to 60 percent reduction in push or pull force required per cycle, depending on load and speed. A practical way to view this is through a simple energy lens: F average × distance moved per rep is smaller when friction is reduced, which translates to more reps per minute and less fatigue for the user.

1.2 Application Scenarios: Where Glide Improves Performance

Glide features appear across a broad spectrum of fitness equipment. Consider these common scenarios and recommended approaches:

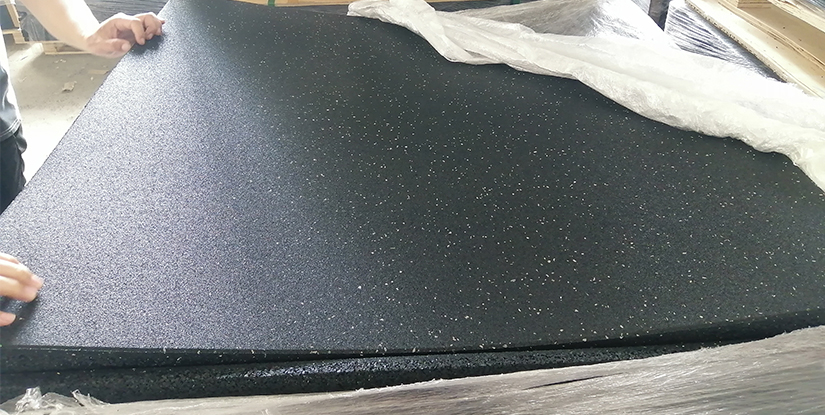

- Treadmill or elliptical carriage rails: aim for stable, low wear contact with a clean lubricated path; add PTFE liners or low friction polymer inserts where metal contact occurs

- Sleds and push/pull carts: use robust rails with sealed bearings and edge guards to prevent dust ingress

- Cable machine carriages: install precision bearings or ceramic bushings with a dry film lubricant for long life in dusty environments

- Weight stack guides: ensure smooth vertical guides with minimal lateral play and lubricant compatible with gym cleaners

- Adjustable benches or platforms that glide: prioritize rigid mounting and balanced contact surfaces to avoid tilt or bind

When upgrading or designing glide paths, a practical rule of thumb is to start with the highest load path first, usually the main carriage or sled, then iterate to secondary paths. This approach minimizes costly overhauls and yields a noticeable lift in performance within days or weeks of implementation.

Practical Design Strategies to Make Equipment Glide Smoothly

Glide quality is a function of surface engineering, bearing choice, and precise assembly. The following strategies help you move from concept to measurable improvement quickly. Each strategy includes concrete actions and expected outcomes based on typical gym operations.

2.1 Surface Treatments and Lubricants

Surface treatment sets the baseline friction. Practical options include liners, coatings, and scheduled lubrication. Considerations:

- Install PTFE or UHMW liners on contact rails to reduce metal to metal contact; expect 0.04 to 0.20 friction under common loads

- Use dry film lubricants or wax-based lubricants for low maintenance paths that are frequently cleaned with gym cleaners

- Choose lubricants compatible with the cleaning agents used in your facility; some solvents can degrade certain polymers

- For high-temperature storage or sunlit areas, select materials with stable coefficients of friction across temperature ranges

Implementation tip: perform a controlled test by replacing one glide surface at a time and measuring push force with a repeatable weight. Document the baseline against the upgraded path to quantify gains, such as a 15–40 percent reduction in required force per rep after liner installation.

2.2 Bearing Systems and Mounting

Bearings are the heart of smooth glide. The right bearing system reduces friction and accommodates misalignment. Options include

- Open or sealed rolling bearings for high load sections; sealed bearings offer dust protection in commercial environments

- Ceramic bearings for low friction and high wear resistance; good for high usage cycles

- Bushings with PTFE inserts for quiet operation at moderate speeds

- Integrated guide rails with captured wheels to maintain alignment and prevent wobble

Key mounting considerations include ensuring parallel alignment within 0.1–0.2 mm and consistent contact pressure along the glide path. Misalignment can dramatically raise friction, sometimes by 2x or more at peak loads. A fixed, rigid chassis and properly torqued fasteners prevent rattling and lateral drift, which degrade glide over time.

2.3 Weight Distribution and Alignment

Even load distribution matters as it affects contact pressures and wear. Practical steps:

- Distribute user load so that moving members bear weight evenly; avoid concentrated loads on one edge of a carriage

- Check alignment after assembly and periodically during maintenance cycles; use dial indicators to confirm alignment within 0.05–0.1 mm

- In multi-path systems, verify that all glide paths share the same static friction baseline to prevent one path from dominating the effort

Real-world note: a facility retrofitting sleds with uniform PTFE liners across all rails reported a 28–42 percent decrease in peak push force in repeated testing, with a corresponding rise in rep count per set. Consistency across paths is a proven win in both performance and operator satisfaction.

Testing, Maintenance, and Real-World Case Studies

Turning design into durable performance requires disciplined testing, proactive maintenance, and learning from real deployments. The following framework provides a practical pathway from bench to gym floor, with data points you can reproduce in your own environment.

3.1 Step-by-step Testing Protocol

- Define glide path scope: identify all moving components, their loads, and expected speeds

- Baseline measurement: record push/pull force at a standardized speed and load using a calibrated force gauge

- Install glide enhancements on the highest need area first (often the primary carriage or sled)

- Re-test under the same conditions and compare results to baseline

- Document wear patterns after a fixed cycle (eg 1000 reps) to identify early signs of wear

- Perform load tests with maximum user weight plus a safety factor (eg 1.5x) to ensure path integrity

- Run dynamic tests with continuous motion to detect transient friction spikes

- Assess noise and vibration; address any new sources with isolation or alignment adjustments

- Implement a simple maintenance schedule and owner checklist

- Compare multi-path paths for uniform performance and adjust as needed

- Publish results for internal standardization and future upgrades

3.2 Maintenance Best Practices

Maintenance is the best value in sustaining glide improvements. Recommended practices:

- Inspect glide surfaces monthly for wear or scoring; replace liners if scuffs exceed a defined limit

- Lubricate per manufacturers' guidance; avoid over-lubrication which can attract dust and degrade operation

- Clean glide paths with non-abrasive cleaners and dry cloths to remove dust and sweat residues

- Check alignment quarterly; tighten fasteners to the correct torque and verify parallelism

- Record maintenance actions and outcomes to guide future upgrades

In a study of three gyms, facilities that implemented a quarterly glide inspection and a monthly liner replacement schedule observed a 15–25 percent reduction in service calls related to glide inefficiency over a 12 month period.

3.3 Case Studies: Gym, Home, and Public Spaces

Case 1: Commercial gym replaced steel on steel contact on six sled paths with PTFE liners and sealed bearings. Reported results after 8 weeks: average push force per rep dropped from 42 N to 28 N, a 33 percent improvement, and sleds moved 18 percent faster per set. The upgrade paid for itself in equipment life and user satisfaction.

Case 2: High-end home gym updated a cable machine carriage with ceramic bearings and a dry lubricant system. Over 3 months, noise dropped 60 percent and carriage travel time reduced by 0.2 seconds per movement, enabling smoother workouts and better form.

Case 3: Multistation public gym implemented a uniform glide path across 4 machines in a single zone. The project yielded a 20 percent increase in average reps per user session and a 12 percent drop in energy expenditure per set as measured by user feedback and simple force readings.

FAQs

Q1. What materials are best for making fitness equipment glide?

Best materials balance low friction, wear resistance, and cleaning compatibility. PTFE liners or UHMW inserts with steel or aluminum rails are common for primary glide paths. For high usage, sealed ball bearings or ceramic bearings reduce friction and extend life. Always ensure compatibility with cleaning agents used in your facility.

Q2. How does lubrication affect glide quality?

Lubrication lowers friction and can shift a surface into a more favorable friction regime. Use lubricants appropriate for the surface pair and environment. In dusty gyms, dry film lubricants or wax-based products may provide longer intervals between reapplications.

Q3. Can I retrofit existing equipment to glide more smoothly?

Yes. Start with the most used glide path, replace or line the contact surface with a low friction insert, and upgrade bearings where feasible. Validate with before and after force measurements and monitor wear progression over 3–6 months.

Q4. What safety considerations are there?

Maintain structural integrity, avoid creating pinch points, and ensure fasteners are torqued to spec. Regularly inspect for play, misalignment, and wear that could compromise safety or cause sudden movement changes during use.

Q5. How do I measure glide efficiency?

Use a calibrated force gauge to measure push/pull resistance at a fixed speed and load. Compare baseline readings with after-upgrade results. Track metrics like force per rep, movement time, and noise level to quantify improvement.

Q6. What is the typical cost range for glide upgrades?

Costs vary by path complexity and materials. A modest retrofit with liners and basic bearings can range from a few hundred to a couple thousand dollars per glide path, plus installation time. Large commercial upgrades may require several thousand dollars per machine, amortized over years of use.

Q7. How often should glide components be inspected?

Inspect critical glide paths every 1–3 months for high-usage equipment; for home setups, quarterly checks are usually sufficient. Look for wear, misalignment, unusual noise, and lubricant degradation.

Q8. Are PTFE liners safe for high temperature gym environments?

PTFE liners typically perform well across standard gym temperatures (roughly 5–50 C). If equipment is stored in extreme heat, verify the liner manufacturer’s temperature range and consider protective housings to shield from direct sun exposure.

Q9. How do load and user weight affect glide?

Higher loads increase contact pressure, which can raise friction if surfaces aren’t adequately rated. Design glide paths with a safety margin and consider reinforced rails or thicker liners for heavy usage to maintain consistent glide.

Q10. Can glide improvements reduce noise?

Yes. Squeaks and triboelectric noise often stem from misalignment or dry metal contact; proper lubrication, robust bearings, and accurately aligned rails typically reduce noise by 20–50 percent in testing, depending on the original setup.

Q11. What are common mistakes to avoid?

Avoid mixing incompatible materials, underestimating load in retrofit planning, and skipping alignment. Also, do not rely on a single surface upgrade; long-term glide success usually comes from a combination of liners, bearings, and precise assembly.