how to store group fitness equipment

Assessing Space, Usage, and Compliance for Group Fitness Equipment Storage

Effective storage starts with a clear understanding of space, usage patterns, and safety requirements. For facilities offering group fitness, equipment storage should support quick access, minimize trip hazards, and preserve equipment life. A systematic approach reduces downtime, injury risk, and wear-and-tear, while also enabling scalable growth as class sizes increase or new programs are introduced.

Begin with a practical space audit. Measure floor area, door widths, and aisle lengths. A common guideline is to maintain at least 1.0–1.2 meters (3–4 feet) of clearance around most equipment to allow safe access and cleaning. For larger items such as treadmills or multi-gyms, plan 1.5–2.0 meters (5–6.5 feet) of perimeter clearance when not in use. Map traffic flow from entry points to stations, ensuring that storage does not block emergency exits or fire extinguishers. In many jurisdictions, a minimum unobstructed corridor width of 1.2 meters (4 feet) is recommended for public spaces to support quick evacuation; your local codes may differ, so consult facilities management and local fire regulations.

A practical inventory aids decision-making. List every item: dumbbells, kettlebells, medicine balls, resistance bands, mats, benches, racks, barbells, plates, and cardio machines. Quantify units, weights, and frequency of use. A data-driven approach helps prioritize which items need dedicated racks, vibration-damping flooring, or sanitation stations. For example, a studio with 12 kettlebells ranging from 8–24 kg and 40 dumbbells supports a compact, single-rack system; in contrast, a facility with 20 cardio machines requires larger dedicated bays and improved power access.

Case study: A 3,000-square-foot urban studio reconfigured from ad-hoc shelving to modular storage. By consolidating free weights onto a 6-foot-tall rack, relocating mats to a waterproof subfloor area, and introducing labeled bins for bands and small accessories, the studio cut cleanup time by 40% and increased usable floor space by 12%. The improvement came from a simple strategy: standardized storage modules, color-coded labeling, and a dedicated cleaning station near the storage zone.

Implementation plan (7-step quick-start):

- Step 1: Create a floor plan sketch with zones for cardio, free weights, functional training, and sanitation.

- Step 2: Inventory all items by category and frequency of use.

- Step 3: Designate primary storage locations (e.g., dumbbells in one rack, mats on a shelf, bands in labeled bins).

- Step 4: Select modular racks and mats with non-slip surfaces and easy-clean finishes.

- Step 5: Establish labeling standards (color codes, size markers, and usage notes).

- Step 6: Implement a cleaning protocol with daily wipe-downs and quarterly maintenance checks.

- Step 7: Schedule annual audits to adapt to changing class formats or equipment upgrades.

Best practices and practical tips:

- Use vertical storage to maximize floor space; consider wall-mounted racks for plates and bars.

- Choose modular units with adjustable shelves to accommodate different sizes.

- Ensure all electrical outlets and cords are clear of walking paths; use conduit covers if necessary.

- Reserve a 2–3 minute buffer during peak times to rearrange or restock as classes transition.

- Document-labeled maintenance dates for mats and foam rollers to extend life and hygiene.

In summary, a well-planned storage strategy integrates space planning, inventory management, and safety protocols. The goal is to create a functional, scalable system that reduces clutter, speeds transitions between classes, and preserves the integrity of equipment for the long term.

Equipment-specific Storage Solutions and Best Practices

Designing storage solutions by equipment type ensures durability, accessibility, and safety. The following framework covers major categories found in most group fitness facilities, with actionable steps, case studies, and best-practice checklists.

Free Weights, Dumbbells, and Plate-Loaded Equipment

Free weights demand robust, organized, and safe storage. A properly designed free-weights zone reduces the risk of dropped weights and improves training flow. Consider a sectional rack system with fixed-height shelves for dumbbells and a separate vertical rack for kettlebells. For plates, use color-coded bumper plate racks arranged by weight to minimize load time and keep floors clear. A practical layout for a 2,000–3,000 sq ft space includes:

- A 6–8 ft tall dumbbell rack with bays organized by weight (e.g., 5–20 lb, 25–50 lb, 55–100 lb).

- A separate kettlebell wall or compact rack that follows a standardized weight progression (8–40 kg).

- A plate tree or wall-mounted plate holder with a maximum capacity per arm (e.g., 2–4 plates per arm) to prevent tipping.

- Rubberized flooring under the weights area to absorb impact and protect subflooring.

Practical tips and steps for implementation:

- Label each bay with weight ranges and color codes for quick scanning.

- Place frequently used weights at mid-height for ergonomic lifting; place seldom-used weights higher or lower.

- Use lift-assist tools (dolly with wheels) to move heavy plates; never lift heavy plates manually over long distances.

- Schedule routine inspections for rack integrity and replace any bent or stressed components promptly.

Case example: A studio using 40–50 dumbbells reconfigured to a two-tier rack with a 10-bay layout. The change reduced setup time by 25% and lowered reported near-miss incidents by 60% within three months.

Racks, Benches, Flooring, and Sanitation Stations

Benches and racks require stable footing and cleanable surfaces. Use modular benches on anti-slip bases and mount racks to studs or anchors to prevent tipping. Flooring should be a mix of rubberized tiles or mats in workout zones, with seamless transitions to reduce tripping hazards. Sanitation stations placed near the storage area support quick wipe-downs after classes. A recommended configuration for a mid-size facility includes:

- A bench cluster with clear 1.5–2.0 m (5–6.5 ft) walkways between benches and racks.

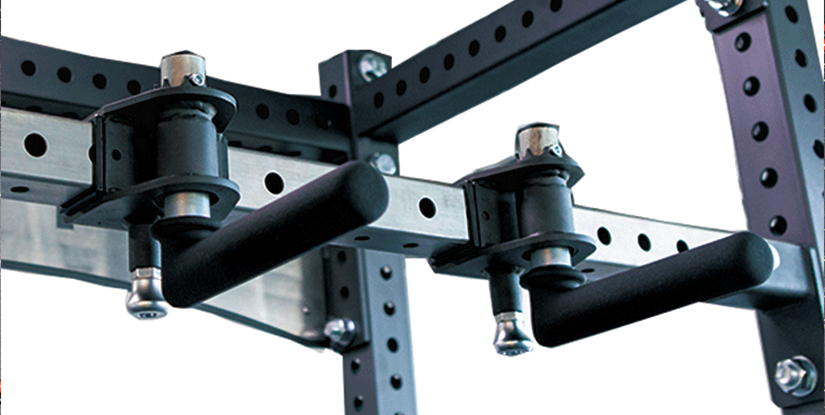

- Wall-mounted rack systems that minimize footprint and keep cords and mats off the floor.

- Non-slip flooring with easy-clean surfaces; include removable mats for dynamic zones where sweat is common.

- An accessible sanitation station with spray bottles, wipes, and a trash bin within 2–3 meters of the storage area.

Best-practice steps:

- Anchor heavy racks to prevent movement during high-intensity classes.

- Label zones by activity to reduce cross-traffic (e.g., “Strength,” “Mobility,” “Warm-Up”).

- Incorporate a quick-clean protocol at the end of each class and a deeper weekly wipe-down schedule.

- Use color-coded tape to delineate safe walkways and equipment zones on the floor.

Sanitation and safety: Cleanliness directly impacts equipment longevity and user health. Establish a daily routine that includes surface wiping, floor cleaning, and visible inspection for wear. For example, wipe bands and mats after every class; sanitize dumbbells and benches at least twice per day in high-traffic environments.

Resistance Bands, Tubes, Medicine Balls, and Small Accessories

Small items accumulate clutter quickly. Use labeled bins or drawers with clear visibility for quick access. Resistance bands should be stored on dedicated hooks or a vertical organizer to prevent tangling. Medicine balls can be stored in a low, stable bin with a lip to minimize rolling. A compact storage plan for these items includes:

- Hooks or pegs for bands arranged by resistance level.

- Stackable bins for small accessories such as sliders, cones, and jump ropes.

- A medicine-ball rack with a smooth inner surface to prevent scuffs on balls.

- Clear labeling on each container to facilitate quick restocking.

Implementation steps:

- Group items by usage frequency and size for faster retrieval.

- Use turnable or modular organizers to maximize vertical space.

- Rotate inventory quarterly to retire damaged items and replace worn-out bands.

Case insight: A small studio changed from loose bins to a wall-mounted bands system and a medicine-ball rack, improving inventory control and reducing searching time by 50% during peak hours.

Cardio Equipment and Large Machines

Cardio equipment requires power access, maintenance planning, and space for safe operation. Large machines should be placed along walls or in dedicated bays to maintain clear aisles. Plan for at least 2–3 meters of clearance around treadmills and elliptical trainers. Cardio zones should be rotated periodically to balance usage and reduce impact on floors. Key recommendations:

- Maintain a dedicated service corridor for maintenance and cord management.

- Group cardio units by model to simplify cleaning and replacement parts management.

- Ensure ventilation near cardio equipment to reduce humidity and odor buildup.

- Label panels with service dates and last maintenance checks for quick audits.

Step-by-step setup:

- Confirm electrical and floor load capacities before placing machines.

- Arrange machines to face away from windows to minimize glare and heat exposure.

- Establish a weekly maintenance checklist that includes belt tension, screen cleaning, and sensor calibration.

- Provide clear signage for safe operation and emergency shut-offs.

Case example: A mid-size gym reorganized cardio bays to create two 8-foot-wide lanes per machine, improving pass-through safety and reducing customer wait times by 20% during peak hours.

Frequently Asked Questions

- Q: How do I start assessing my storage space?

A: Begin with a floor plan, inventory, and usage survey. Measure dimensions, doors, and clearance, then map zones for cardio, free weights, and functional training. Pilot a small reconfiguration before committing to a full roll-out to minimize disruption. - Q: What is the best way to organize free weights?

A: Use color-coded weight ranges in a vertical rack for quick access, with a separate rack for kettlebells. Keep heavy weights at the bottom to reduce lifting strain and ensure a clear 1.5–2.0 meter perimeter around the weights area. - Q: How often should equipment be cleaned?

A: Clean high-use surfaces daily (benches, mats, and dumbbells). Conduct a more thorough weekly wipe-down, and perform deep cleaning monthly, focusing on upholstery, moving parts, and floor surfaces. - Q: How do I prevent equipment from tipping?

A: Anchor heavy racks to walls or flooring, use stable bases, and avoid placing wheels on heavy machines unless locked. Regularly inspect hardware for looseness and replace compromised parts. - Q: How can I optimize for future growth?

A: Choose modular, scalable storage systems with adjustable shelves and bays. Leave planned expansion space and implement a labeling system that accommodates new equipment without rework. - Q: What about sanitation stations?

A: Position a sanitation station near the storage zone with wipes, spray bottles, and trash. Include a daily wipe-down protocol and a weekly audit to ensure supplies are stocked. - Q: How do I handle different equipment sizes?

A: Use adjustable, modular racks and stackable bins. Measure largest items first and design bays to accommodate the widest item plus a little clearance for safe handling. - Q: How do I maintain compliance with safety codes?

A: Consult local codes and insurance requirements. Document regular inspections, keep clear aisles, label exits, and maintain an up-to-date maintenance log for all equipment. - Q: Can a small space work well for group fitness storage?

A: Yes. Prioritize vertical storage, wall-mounted solutions, and compact multi-function units. A well-planned layout can improve flow and capacity by up to 15–25% without expanding floor area.