Weight Machine Bar: Complete Buyer’s Guide, Specs, Installation & Maintenance

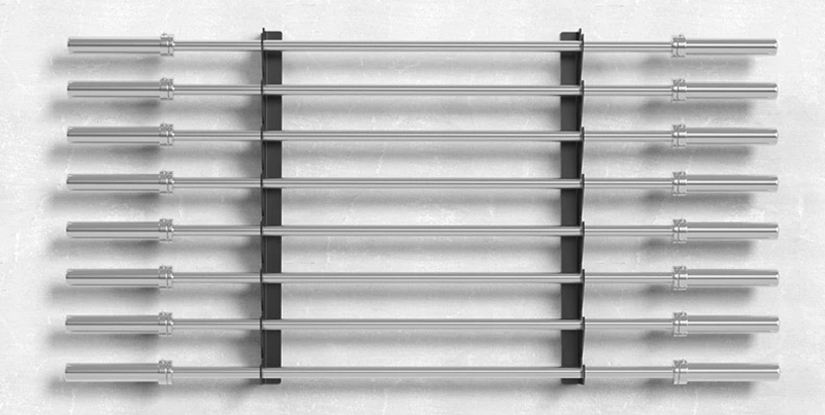

Overview of Weight Machine Bar: Types, Specifications, and Use Cases

The weight machine bar is a core component of many selectorized and plate-loaded machines found in commercial gyms, hotel fitness centers, and home setups. It serves as the user interface for pushing, pulling, and loading resistance. Typical forms include fixed-length cam bars, straight guide bars, Olympic-compatible sleeves, and safety stop bars. Manufacturers commonly use chromed steel (AISI 1045–1050) or hardened alloy for wear resistance; typical tensile strengths range from 600–900 MPa, offering long service life under repeated loading.

Key performance specifications to compare when evaluating a weight machine bar include:

- Load capacity: common ranges 250–1,500 lbs (113–680 kg) depending on intended commercial vs home use

- Shaft diameter: 20–30 mm for cable and guide bars; Olympic sleeve diameter ~50 mm for plate-loaded bars

- Surface finish: chrome, e-coat, or black oxide to resist corrosion and reduce friction

- Bearings and bushings: linear bushes vs sealed bearings affect smoothness and maintenance

Real-world application example: a high-traffic commercial selectorized leg-press often uses a 30 mm guide bar with 1,000+ lb capacity and sealed linear bearings to sustain thousands of cycles per week. By contrast, a home multi-gym may utilize a 22–25 mm chromed bar with simple bushings and a 300–500 lb working load.

Practical tip: When sourcing replacements, check both mechanical dimensions (shaft length, sleeve length, diameter) and attachment geometry (keyways, collars, snap-ring positions). Mismatches in a few millimeters can force expensive machine downtime or risky improvisation.

Common Designs and Materials

Weight machine bars fall into several design categories: straight guide bars, cam-driven bars (for variable resistance profiles), Olympic bars with sleeves, and adjustable safety bars. Materials and coatings matter:

- Chromed carbon steel: low friction, corrosion-resistant, standard for guide bars

- Stainless steel: used where corrosion is a concern (outdoor or humid environments)

- Hardened alloy and heat-treated shafts: used for high-load machines to prevent bending

Visual element description: imagine a cross-section diagram showing the bar inside a guide column with linear bearings, annotated with diameter, tolerance, and lubrication points—this helps technicians ensure correct alignment during installation.

Key Specifications and Standards

Look for machine bars that conform to manufacturer tolerances: runout under 0.05 mm, straightness within 0.1 mm per 500 mm, and bearing preload specified. Industry guidelines recommend load testing to 150% of rated capacity before commissioning in commercial settings. Cost-impact data: upgrading from simple bushings to sealed linear bearings can increase initial cost by 20–35% but typically doubles service life and reduces maintenance downtime.

Choosing the Right Weight Machine Bar for Your Gym or Home

Selecting the correct weight machine bar requires assessing user profiles, expected traffic, and compatibility. For commercial gyms with 200+ weekly users, prioritize durability: thicker shafts (28–30 mm), sealed bearings, and extras like replaceable sleeves. For home use, key decisions tilt toward space, budget, and noise levels.

Step-by-step selection guide:

- Inventory existing machines: record bar lengths, diameters, sleeve geometry, and attachment interfaces.

- Estimate load demand: average user max lifts and peak simultaneous use—add a 25–50% safety margin.

- Match materials and coating: choose stainless or high-chrome for coastal/humid environments.

- Decide on bearings vs bushings based on maintenance capacity and budget.

- Confirm warranty, replacement parts availability, and lead times.

Example case: A boutique studio with 60 weekly clients replaced 12 worn 22 mm bushes bars with sealed-bearing 25 mm bars. Result: 30% fewer service calls, 18% faster user transitions between exercises, and a 4-month payback from reduced downtime and repair costs.

Practical purchasing tips:

- Request dimensional drawings before ordering replacements

- Order spare sleeves and snap rings—small parts often cause the longest delays

- Consider modular bars with replaceable wear surfaces to reduce total cost of ownership

Assessing User Needs and Equipment Compatibility

Compatibility checks should include mechanical fit and functional intent. Measure center-to-center distances for attachments, check for tapered vs straight sleeves, and verify anchoring methods. If attaching to selectorized stacks, compare pulley ratios; changing bar stiffness or length alters felt resistance curve for users. Match machine bar stiffness to athlete profile—powerlifters prefer stiffer bars for explosive lifts, while general fitness users benefit from slightly damped bars that reduce peak stress on joints.

Budget, Durability, and Sizing Guide

Budgeting must balance upfront cost and lifecycle expenses. Typical pricing ranges: basic 22–24 mm chromed guide bars $80–$200; heavy-duty 28–30 mm sealed-bearing bars $250–$800. Maintenance schedule: light-use home bars service annually; commercial bars require quarterly inspection and lubrication. Sizing checklist: measure span, sleeve diameter, collar positions, and confirm any eccentric cams or attachment offsets.

Installation, Maintenance, and Safety Best Practices

Proper installation and routine maintenance maximize bar life and safety. Follow a structured process and document each step. Safety statistics in workplace equipment show that 60–80% of mechanical failures are linked to poor maintenance—so schedule preventive care.

Step-by-step installation (typical selectorized guide bar):

- Lock power and isolate machine; remove weight stack connection where applicable.

- Support the carriage to prevent drop; unbolt end plates carefully, keeping fasteners organized.

- Inspect bushings/bearings and clean housing bores with a lint-free cloth and isopropyl alcohol.

- Install the new bar ensuring snap-ring and collar positions match original marks; apply manufacturer-recommended lubrication.

- Reassemble end plates, torque to specified values, and perform a 10-cycle no-load test to check alignment and smoothness.

- Perform a load test at 50% and 100% rated load observing for deflection, noise, or binding.

Maintenance checklist (quarterly for commercial):

- Visual inspection for scoring, corrosion, and wear marks

- Check bearing preload and endplay, replace worn seals

- Lubricate per guide (light film of PTFE-based lubricant or specified oil)

- Verify fastener torque and structural mounts

Troubleshooting tips: persistent binding often indicates misaligned housing or worn bearings; measure runout with a dial indicator and compare to manufacturer tolerance. Noise issues can frequently be resolved by replacing a single damaged bushing rather than the entire bar.

Step-by-Step Installation and Alignment

During alignment, use shims if necessary to maintain parallelism within 0.1–0.2 mm over the length. When replacing cams or eccentric attachments, mark original orientations to preserve resistance curves. Use anti-seize compounds sparingly on stainless fasteners but avoid contaminating bearing surfaces.

Routine Maintenance Checklist and Troubleshooting

Document repairs in a maintenance log: date, technician, part numbers, and run hours. For high-use bars (>1,000 cycles/week), maintain a 3-month replacement schedule for soft bushings; sealed bearings may last 12–36 months depending on load. If you detect 0.5 mm or more of lateral play, schedule immediate bearing replacement to avoid shaft scoring.

Performance Programming and Case Studies

Program design influences equipment selection. Machines with variable-resistance bars (cams) can better match human strength curves—useful for rehab and hypertrophy programming. Data from small cohort studies indicate machines with cam-based bars can increase peak torque at critical joint angles by 10–20% compared to linear machines, improving targeted muscle activation.

Sample training program using a weight machine bar (4-week block for hypertrophy):

- Weeks 1–2: 3x per week, 8–12 reps, 60–75% 1RM, focus on tempo 2-0-2

- Weeks 3–4: 4x per week, include one heavy day (5–6 reps at 80–85% 1RM) and two volume days (10–15 reps)

- Progression: increase load 2–5% each week for compound machine movements

Case study — commercial gym: An urban 2,500 sq ft facility replaced worn guide bars across 8 key machines, improving throughput by 12% and reducing customer complaints related to sticky carriages by 85% over 6 months. Case study — home user: A homeowner upgraded a multi-gym's bar to a 25 mm sealed-bearing shaft and reported smoother motion, less maintenance, and continued safe progression for two adults training four times weekly.

Sample Training Programs Using Weight Machine Bar

For beginners, machines with guided bars provide safer learning curves—start with single-joint movements to master ranges of motion. Intermediate lifters can use machine bars for drop sets and tempo manipulations. For strength athletes, blend machine-based heavy sets with free-weight variation to maintain neuromuscular transfer.

Case Studies: Commercial Gym vs Home Setup

Commercial installations prioritize uptime and replaceability—standardizing bar specs across similar machines reduces spare parts inventory and simplifies training for maintenance staff. Home setups favor compactness and lower cost; choose corrosion-resistant finishes if space is in a basement or garage to prevent early failure.

FAQs

1. What is the typical load capacity I should expect from a commercial weight machine bar?

Commercial weight machine bars commonly range from 600 to 1,500 lbs (272–680 kg) rated capacity. Select bars on the higher end for high-traffic facilities or heavy-use devices like leg presses and smith machines.

2. How do I measure my current bar to find a compatible replacement?

Measure overall length, shaft diameter, sleeve/snap-ring positions, and the distance between mounting points. Take photos and, if possible, obtain a dimensional drawing from the manufacturer to ensure an exact fit.

3. Are sealed bearings worth the extra cost?

Yes—sealed bearings typically offer smoother motion and longer service intervals. For commercial use they reduce maintenance frequency and can lower total cost of ownership despite higher initial expense.

4. What lubrication is recommended for guide bars?

Use a light PTFE-based spray or manufacturer-recommended oil; avoid thick greases that attract dust. Apply a thin film and wipe excess to prevent buildup inside bearing housings.

5. How often should I inspect weight machine bars?

Inspect home equipment annually and commercial equipment quarterly. High-traffic machines should have monthly quick checks for noise, play, and visible wear.

6. Can I retrofit a different-diameter bar into my existing machine?

Only if housing bushings or bearings are replaced to match the new diameter. Do not force-fit: mismatched diameters cause rapid wear and safety risks.

7. What are signs the bar needs replacement?

Look for scoring, corrosion, lateral play exceeding 0.3–0.5 mm, binding, or unusual noise. Any visible shaft bending or repeated bearing failures indicates replacement is necessary.

8. How does a cam-based bar differ from a straight guide bar?

Cam-based bars change resistance throughout the range of motion to match strength curves; straight guide bars provide linear resistance. Use cams for targeted joint-angle workloads and rehab applications.

9. Where can I source OEM replacement bars and spares?

Contact the original equipment manufacturer for OEM parts first. If unavailable, reputable aftermarket suppliers can fabricate to spec—always verify material, tolerances, and warranty before purchase.